Pile shoe of drainage plate pile driver

A drainage board and pile driver technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of reducing belt-back rate, high belt-back rate, and low work efficiency, so as to reduce belt-back rate and prevent belt-back Awards, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

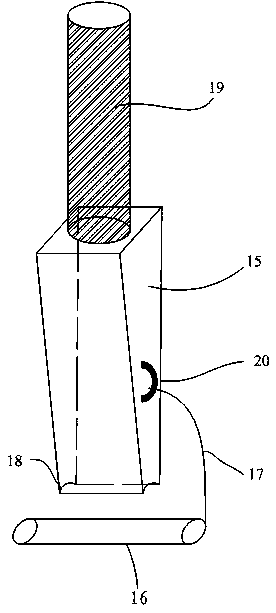

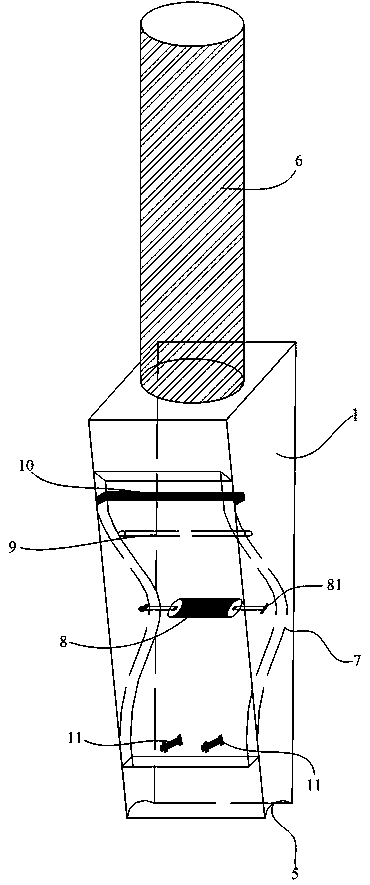

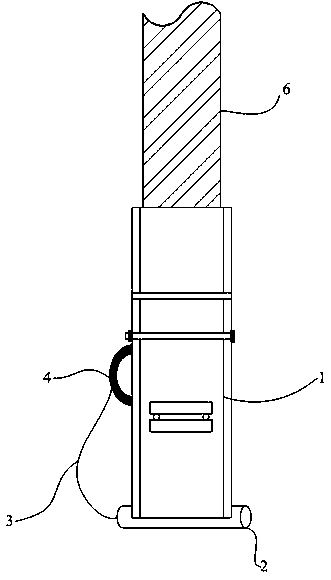

[0021] see Figure 2-Figure 5 , an embodiment of the nozzle of a drainage board pile driver according to the present invention, comprising a nozzle housing 1, a fixing pin 2 and a connecting chain 3, one side of the nozzle housing 1 is provided with a fixing part 4, and the nozzle The bottom end of the housing 1 is provided with a spout 5, the fixed pin 2 is clamped in the spout 5, one end of the connecting chain 3 is connected with the fixing piece 4, and the other end is fixed with the fixed pin 2 connection, the upper end of the pile nozzle housing 1 is fixedly connected with the pile pipe 6, and also includes a drain plate anti-retraction assembly, and the drainage plate anti-retraction assembly includes an arc-shaped elastic plate 7, an eccentric shaft 8 and a pressing member 9 , the inner wall of the pile nozzle housing 1 is provided with an insertion slot 10, the arc-shaped elastic plate 7 passes through the insertion slot 10 and its upper end is clamped in the insertion s

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap