Temperature-stable high-Q-value niobium tantalite microwave dielectric ceramic and preparation method thereof

A microwave dielectric ceramic and temperature-stable technology, applied in the field of niobium tantalate microwave dielectric ceramics and their preparation, can solve problems such as poor temperature stability, and achieve the effects of no pollution in the process, broad application prospects and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

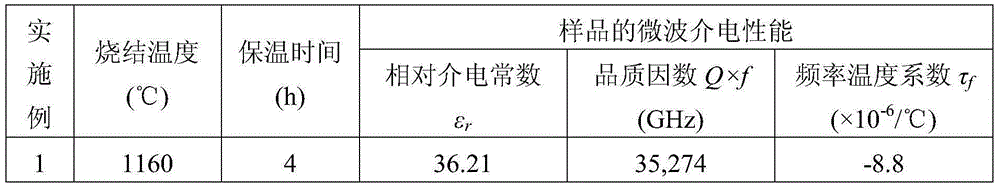

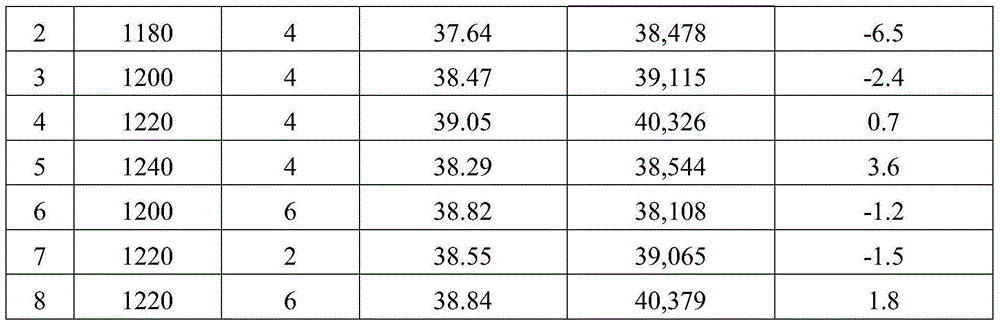

[0018] The present invention is further illustrated by specific examples below. The raw materials used in the examples are all commercially available analytical reagents (purity greater than 99.9%). Specific examples are as follows.

[0019] (1) The raw materials ZnO, CoO, ZrO 2 , Nb 2 O 5 , Ta 2 O 5 Respectively weigh the ingredients by massaging ratio 0.85:0.15:1:1:1;

[0020] (2) Mix the powders prepared above and put them in a ball milling tank, add zirconia balls and deionized water, and mill them on a planetary ball mill for 6 hours. The mass ratio of powder, zirconia balls and deionized water is 1 :1:1.5; Place the ball milled raw materials in an infrared drying oven at 100°C and dry them, and then pass through a 40-mesh sieve after drying to obtain a powder with uniform particles;

[0021] (3) Pre-fire the above-mentioned uniformly mixed powder at 950°C for 2 hours to synthesize frit;

[0022] (4) Add 2.05% polyvinyl alcohol by mass to the pre-fired frit, and then press 0.43 (Zn

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap