Oil and water separation method and oil and water separator

A technology of oil-water separation and oil-water separator, which is applied in separation methods, filtration separation, liquid separation, etc., and can solve problems such as costing a lot of manpower and material resources and consuming huge energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

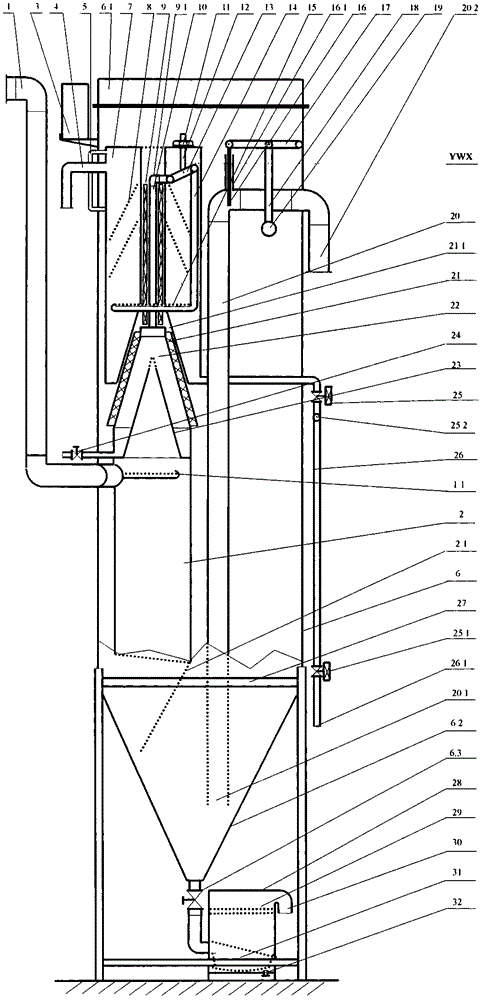

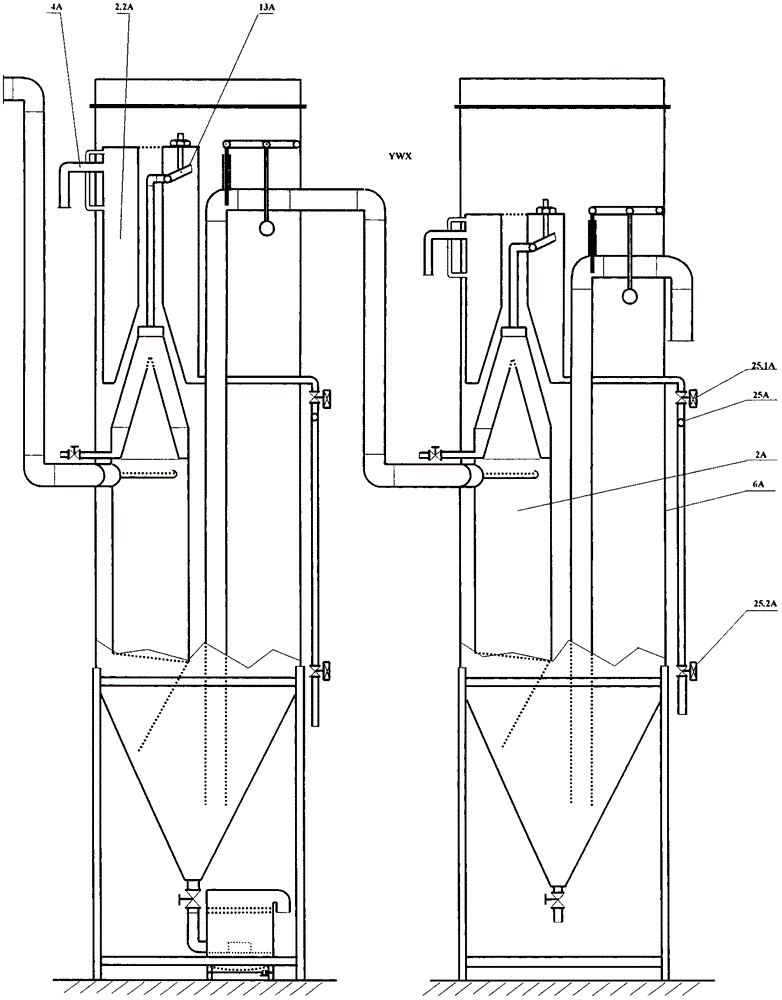

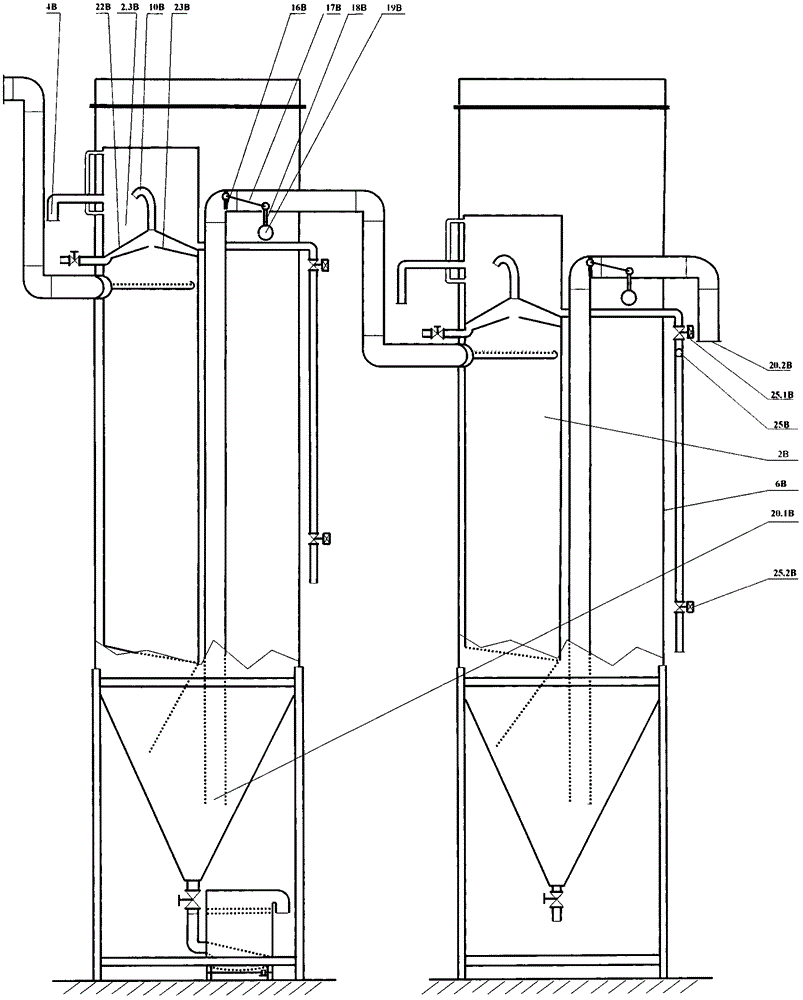

Image

Examples

Embodiment Construction

[0051] In order to realize the purpose of the present invention, the present invention has taken the following specific measures.

[0052] Measure 1, the vertical oil-water separation chamber is preferred, so that the vertically downward earth's gravitational force acting on the oil droplets and water droplets will appear without component force at all times.

[0053] The second measure is to determine the sufficient height of the oil-water separation chamber to ensure the multiples of the mechanical effect produced under the condition that the action time of oil-water separation, the separation stroke and the force of the water drops remain unchanged.

[0054] The third measure is to set a special-shaped U-shaped tube with an appropriate cross-sectional area ratio.

[0055] Measure 4: Set up the flow channel of the special-shaped U-shaped pipe to ensure that the oil with low density enters the branch pipe with a small cross-sectional area, and the water body with a high densi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap