Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Separation technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plant source alcohol soluble protein and its preparation method

InactiveCN1634613APro-proliferativePromote generationPharmaceutical containersSurgeryAlcoholSeparation technology

Owner:SHANGHAI JIAO TONG UNIV

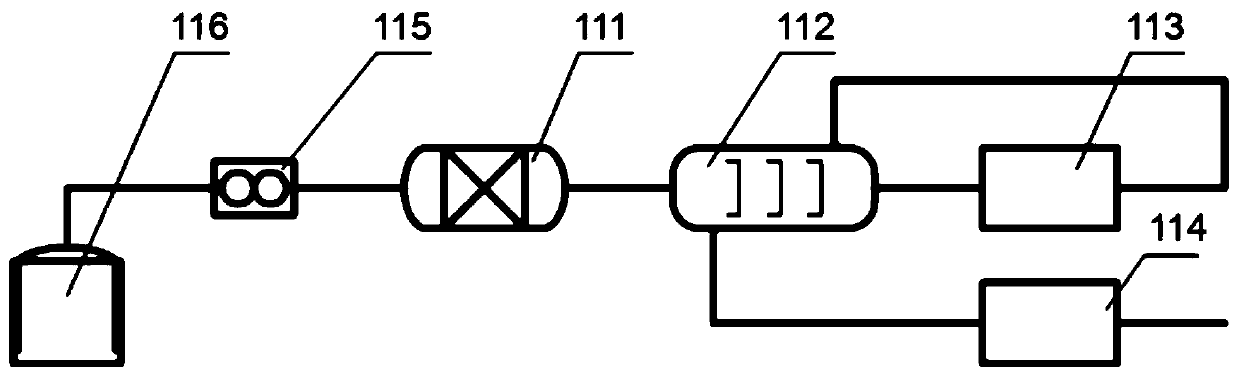

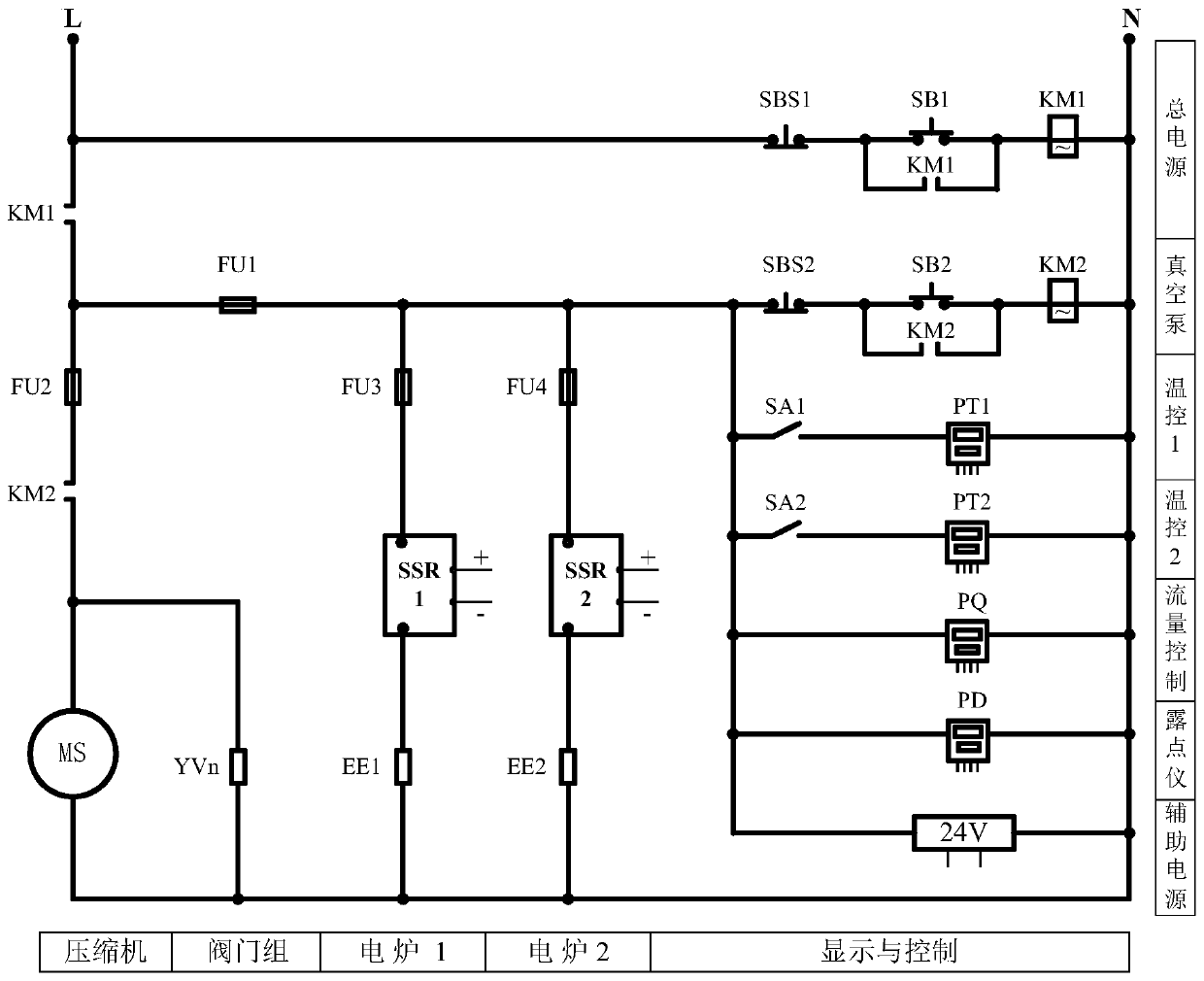

System for removing tritium from high-humid air

PendingCN109887632AAchieve protectionClear in timeRadioactive decontaminationSeparation technologyEngineering

Owner:绵阳大控科技有限公司

Refining and extracting method of dextran by membrane separation

ActiveCN102988989AHigh purityImprove product qualitySemi-permeable membranesBlood disorderFiltration membraneSeparation technology

Owner:JIANGSU JIUWU HITECH

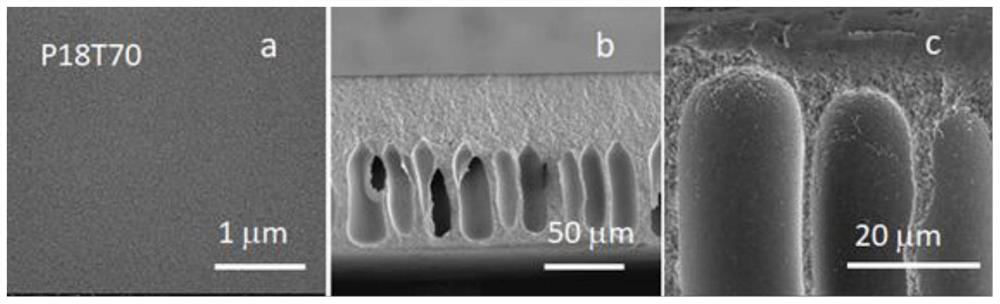

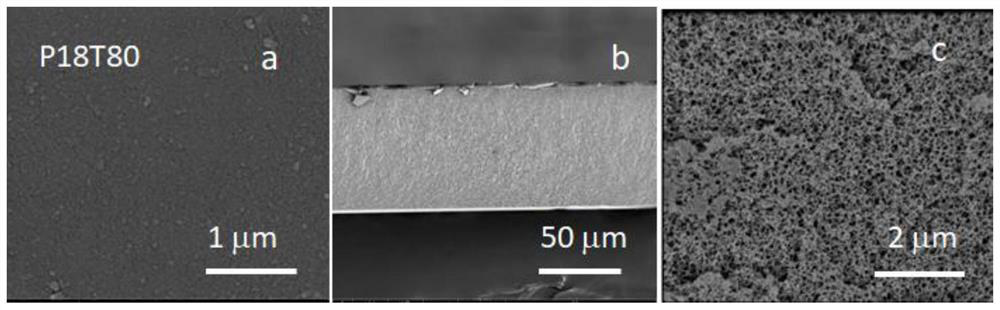

Method for preparing high-performance hydrophilic modified polyacrylonitrile membrane by combining in-situ modification with phase separation technology

InactiveCN111686595AReduce productionImprove development efficiencySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPolymer scienceChemical composition

Owner:XILONG SCI CO LTD

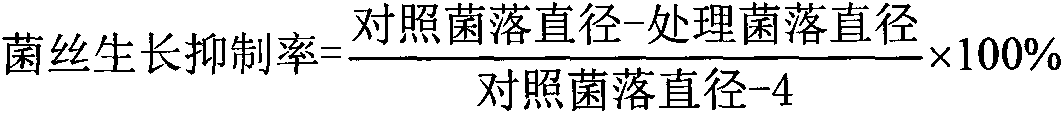

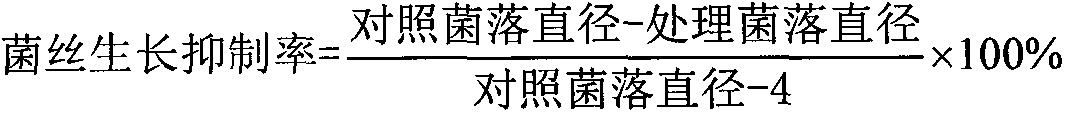

Use of Streptomyces sioyaensis metabolite in prevention and control of Botrytis cinerea

Owner:CHINA JILIANG UNIV

Method for separating and purifying ganoderan based on field flow separation technology

ActiveCN114874349AHigh purityHigh activityChemical industryUltrafiltrationUltrafiltrationSeparation technology

The invention provides a method for separating and purifying ganoderan based on a field flow separation technology. According to the method, extracted ganoderma lucidum crude polysaccharide is firstly subjected to protein removal for four times by adopting a Sevag method, then passes through an AF4 pool channel, is subjected to ultrafiltration for a period of time by adopting ultrapure water as a carrier liquid and adopting a 10kDa renewable cellulose membrane at an ultrafiltration flow rate of 0.2 mL / min, and finally is subjected to asymmetric field flow separation, ultrapure water is adopted as a carrier liquid during asymmetric field flow separation, and ultra-pure water is adopted as an ultra-pure liquid during asymmetric field flow separation. And the initial cross flow velocity index is reduced to 0.05 mL / min. According to the method, the protein removal frequency is reduced in the ganoderma lucidum polysaccharide separation and purification process, the carrier liquid in the whole process is ultrapure water, the dialysis desalting step is not needed, the separation and purification efficiency is improved on the basis of protecting the activity of the ganoderma lucidum polysaccharide, and the high-purity ganoderma lucidum polysaccharide is obtained.

Owner:HEBEI UNIVERSITY

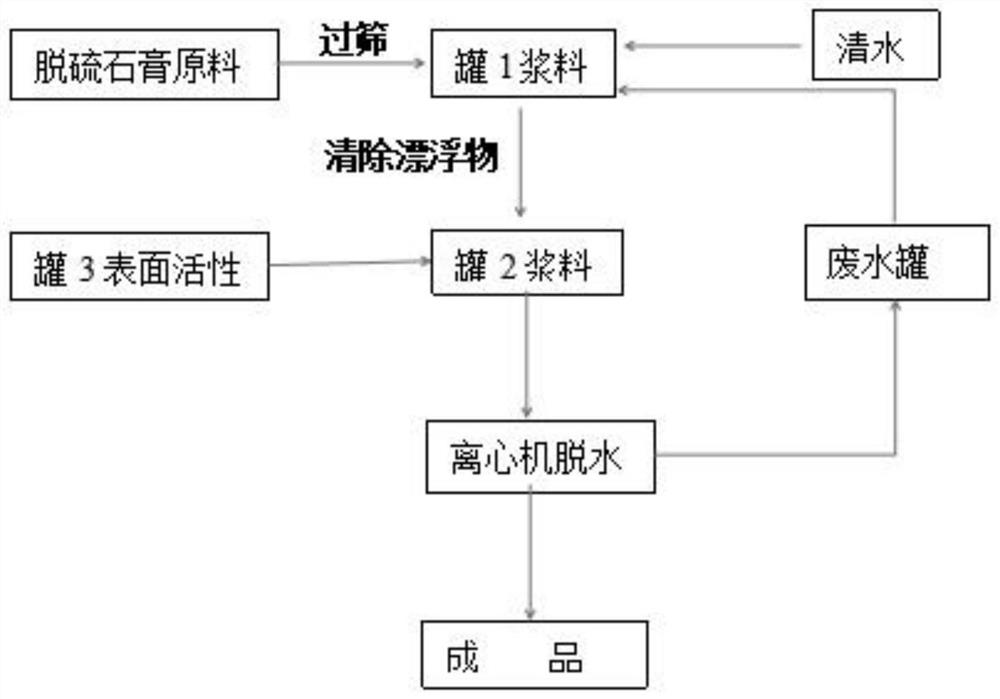

Preparation method for reducing content of organic matter in desulfurized gypsum

PendingCN113135585ASimple processLow costCalcium/strontium/barium sulfatesSeparation technologyActive agent

Owner:SHENZHEN QINGQINGYUAN TECH

Gas-liquid separator

InactiveCN111249806AAvoid incomplete separationIncrease flow ratePositive displacement pump componentsDispersed particle separationSeparation technologyEngineering

Owner:罗辉

Free radical polymerization-based preparation method of water-based coating

The invention discloses a free radical polymerization-based preparation method of a water-based coating. The preparation method comprises the following steps: (1) obtaining liquid illegal cooking oilby adopting a solid-liquid separation technology, then washing the liquid illegal cooking oil respectively with deionized water and a strong-polarity organic solvent in which the illegal cooking oil cannot be dissolved, and finally adding a decoloring agent till the illegal cooking oil is faint yellow, transparent and clear liquid, thus obtaining purified illegal cooking oil; and (2) adding the deionized water, a pH modifier, an emulsifier, a dispersant, an initiator, the purified illegal cooking oil and acrylic ester into a reaction kettle in sequence according to a weight ratio of 90:(0.15-0.23):(1.6-2.2):(0.1-0.5):(0.5-1.5):(43-54):(40-60), and stirring for 10 to 14 min at a stirring speed of 300-800 r / min, thus obtaining illegal cooking oil emulsion. According to the free radical polymerization-based preparation method disclosed by the invention, instable unsaturated oil with low molecular weight is subjected to free radical polymerization to form stable copolymer resin water emulsion with high polymerization degree, so that the prepared water-based coating is high in film forming property and adhesive force and can be widely applied to the field of decoration of a building external wall and the like.

Owner:CHENGDU MITRE NEW MSTAR TECH CO LTD

Efficient oil-water separation device

ActiveCN114212904AImprove stabilityRealize automatic impurity removalFatty/oily/floating substances removal devicesTreatment involving filtrationSeparation technologyOil water

The invention relates to an efficient oil-water separation device, and relates to the field of oil-water separation technologies. The oil-water separation device comprises a separation device body, an oil storage tank arranged below the separation device body, a supporting frame connected to the upper portion of the oil storage tank in a sliding mode, a storage bin fixedly arranged on the supporting frame, an oil outlet pipe arranged below the storage bin, a control valve arranged on the oil outlet pipe and a filter screen arranged at a feeding port of the separation device body. The impurity removing mechanism is arranged between the filter screen and the separation device body and used for removing impurities on the filter screen, and the moving mechanism is arranged between the supporting frame and the oil storage tank and used for driving the supporting frame to slide towards the side away from or close to the separation device body. The oil-water separator has the beneficial effects that a worker can conveniently remove impurities in the oil-water separator, the operation stability of the oil-water separator is improved, the labor intensity of the worker is relieved, and the treatment efficiency of the oil-water separator is improved.

Owner:SHENZHEN HENGXINGSHENG KITCHENWARE CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap