Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9 results about "Ultrapure water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrapure water (also UPW or high-purity water) is water that has been purified to uncommonly stringent specifications. Ultrapure water is a commonly used term in the semiconductor industry to emphasize the fact that the water is treated to the highest levels of purity for all contaminant types, including: organic and inorganic compounds; dissolved and particulate matter; volatile and non-volatile, reactive and inert; hydrophilic and hydrophobic; and dissolved gases. ***

Method for separating organic matters in reverse osmosis concentrated water

ActiveCN104230079AAvoid the influence of the separation effectImprove reliabilityMultistage water/sewage treatmentChemistryUltrapure water

The invention relates to a method for separating organic matters in reverse osmosis concentrated water. The method comprises the following steps: filtering reverse osmosis concentrated water via a glass fiber filter membrane, passing the reverse osmosis concentrated water through an XAD-8 resin column, washing the XAD-8 resin column by ultrapure water, and mixing the washing liquid and effluent to obtain mixed effluent; backwashing the XAD-8 resin column by hydrochloric acid, and backwashing the XAD-8 resin column by pure water, wherein the effluent component is a hydrophobic alkaline organic matter; regulating the pH value of the mixed effluent to be 2 by hydrochloric acid, and passing the mixed effluent through serially connected XAD-8 resin column and XAD-4 resin column, wherein the effluent is a hydrophilic organic matter; backwashing the XAD-8 resin column by sodium hydroxide, and backwashing the XAD-8 resin column by pure water, wherein the effluent component is a hydrophobic acidic organic matter; backwashing the XAD-4 resin column by the sodium hydroxide, and backwashing the XAD-4 resin column by pure water, wherein the effluent is a weakly hydrophobic acidic organic mater; carrying out Soxhlet extraction on the dried XAD-8 resin by methanol, carrying out rotary vaporization on the prepared extracting solution until the extracting solution is dry, and dissolving by pure water to obtain the hydrophobic neutral organic matters. According to the separation method provided by the invention, organic matters in the reverse osmosis concentrated water can be effectively separated.

Owner:PETROCHINA CO LTD +1

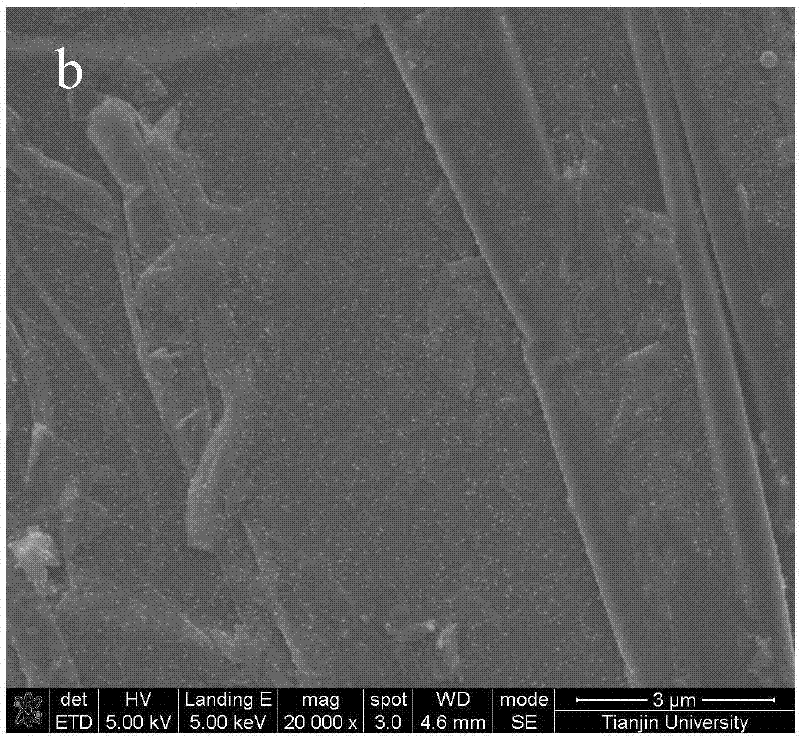

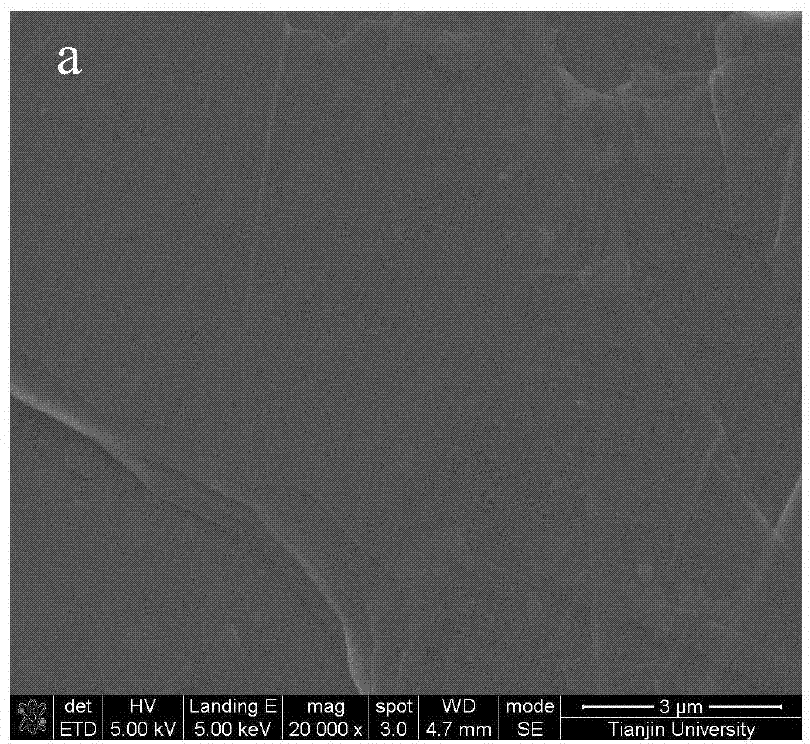

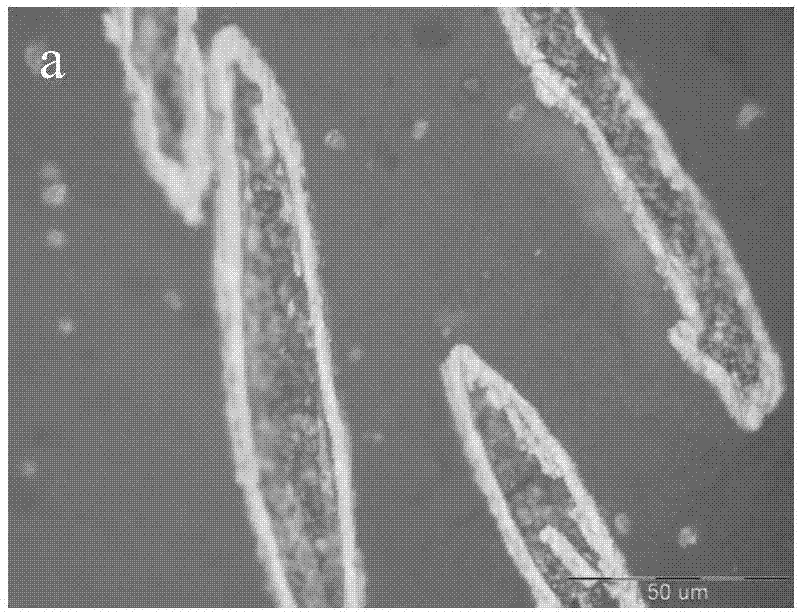

Preparation method of graphite sheet surface chemical plating iron-nickel alloy layer

InactiveCN104195532AImprove bindingHigh hardnessLiquid/solution decomposition chemical coatingChemical platingGraphite

Owner:TIANJIN UNIV

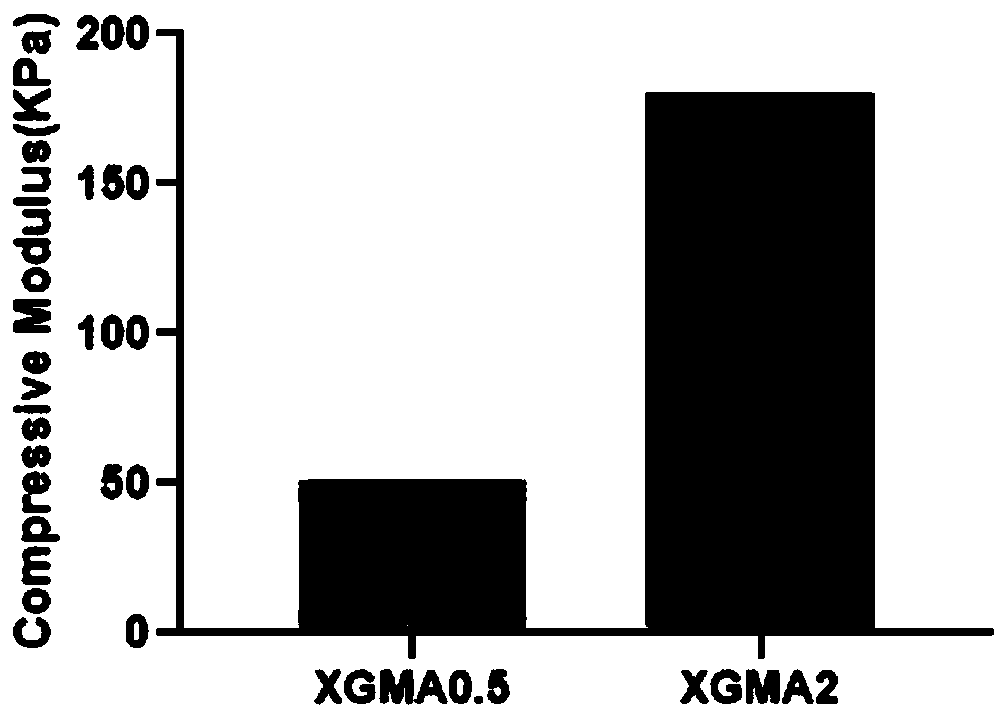

3D-printed xanthan glue gel scaffold and preparation method thereof

InactiveCN110680954AShape controllableHigh precisionTissue regenerationProsthesisCartilage cellsComputer printing

Owner:GUANGXI MEDICAL UNIVERSITY

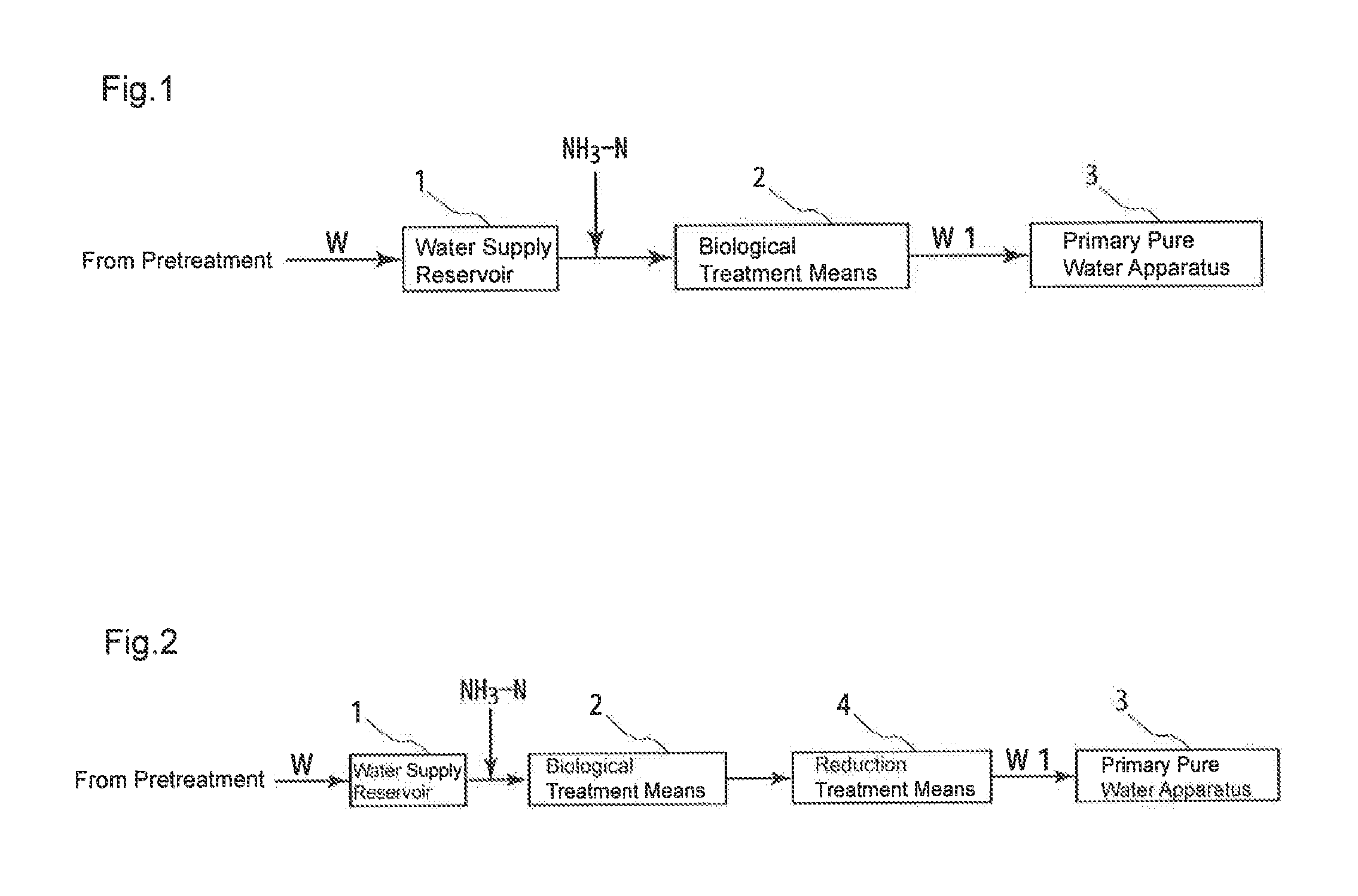

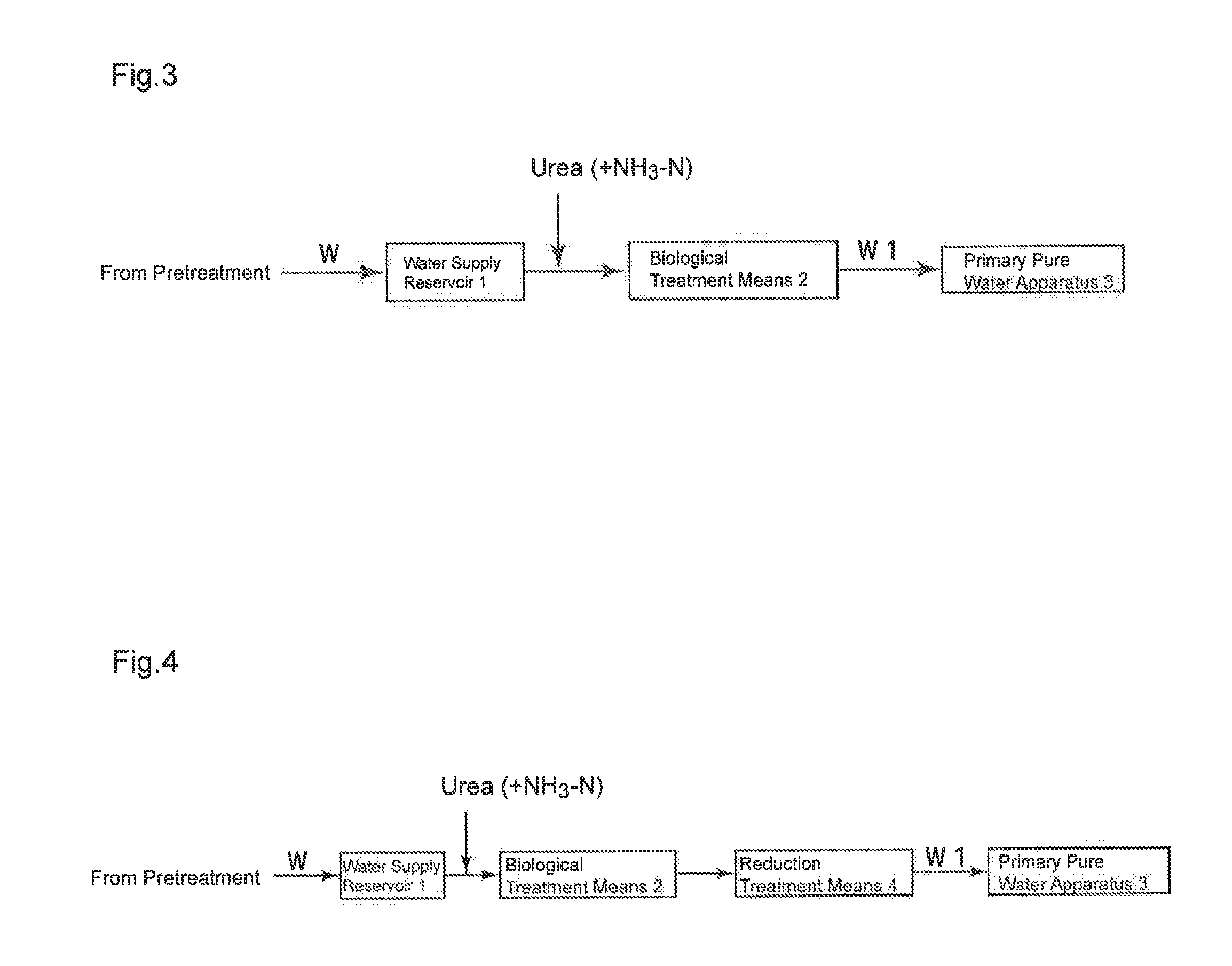

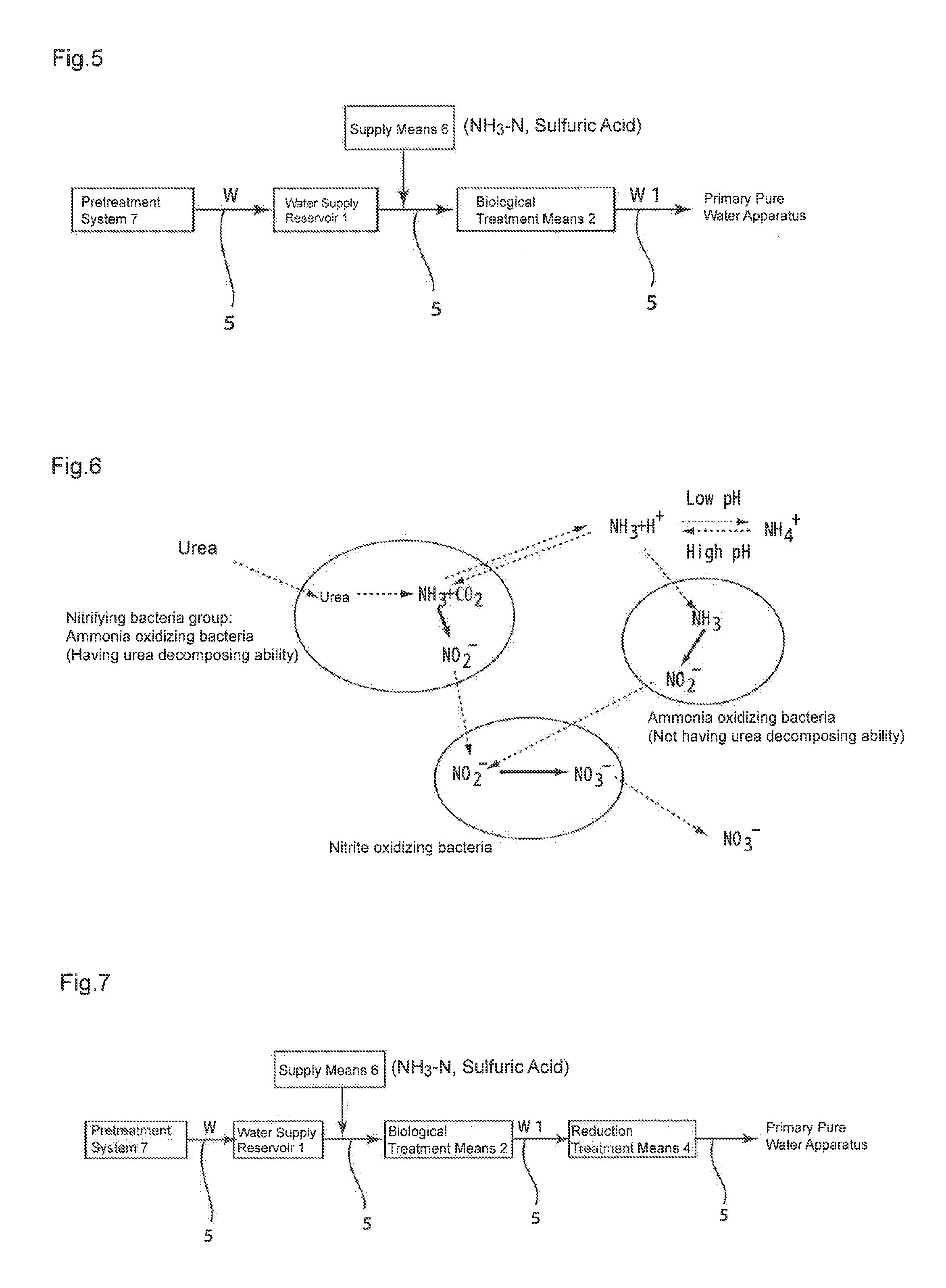

Water treatment method and ultrapure water production method

InactiveUS20130105389A1Enhance urea decomposing abilityReduced activityWater treatment compoundsWater contaminantsUrea derivativesAmmoniacal nitrogen

Owner:KURITA WATER INDUSTRIES LTD

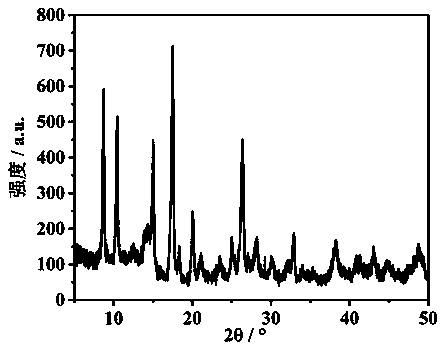

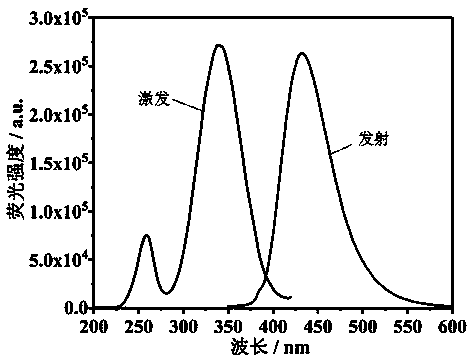

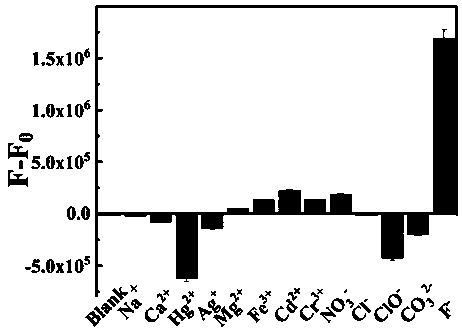

Preparation of water-soluble metal-organic framework composite material and application of water-soluble metal-organic framework composite material in detecting concentration of fluorine ions in water

InactiveCN111454461AFluorescent signal enhancementRealize specific identification detectionFluorescence/phosphorescenceLuminescent compositionsFluoProbesMetal-organic framework

Owner:NORTHWEST NORMAL UNIVERSITY

Method for separating and purifying ganoderan based on field flow separation technology

ActiveCN114874349AHigh purityHigh activityChemical industryUltrafiltrationUltrafiltrationSeparation technology

The invention provides a method for separating and purifying ganoderan based on a field flow separation technology. According to the method, extracted ganoderma lucidum crude polysaccharide is firstly subjected to protein removal for four times by adopting a Sevag method, then passes through an AF4 pool channel, is subjected to ultrafiltration for a period of time by adopting ultrapure water as a carrier liquid and adopting a 10kDa renewable cellulose membrane at an ultrafiltration flow rate of 0.2 mL / min, and finally is subjected to asymmetric field flow separation, ultrapure water is adopted as a carrier liquid during asymmetric field flow separation, and ultra-pure water is adopted as an ultra-pure liquid during asymmetric field flow separation. And the initial cross flow velocity index is reduced to 0.05 mL / min. According to the method, the protein removal frequency is reduced in the ganoderma lucidum polysaccharide separation and purification process, the carrier liquid in the whole process is ultrapure water, the dialysis desalting step is not needed, the separation and purification efficiency is improved on the basis of protecting the activity of the ganoderma lucidum polysaccharide, and the high-purity ganoderma lucidum polysaccharide is obtained.

Owner:HEBEI UNIVERSITY

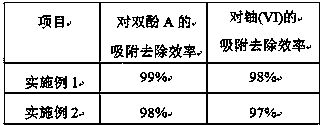

Method for preparing magnetic hybridized microsphere adsorption material for sewage treatment

InactiveCN110743488AReduce contentImprove adsorption capacityOther chemical processesRadioactive contaminantsMicrosphereDissolution reaction

Owner:邵帅

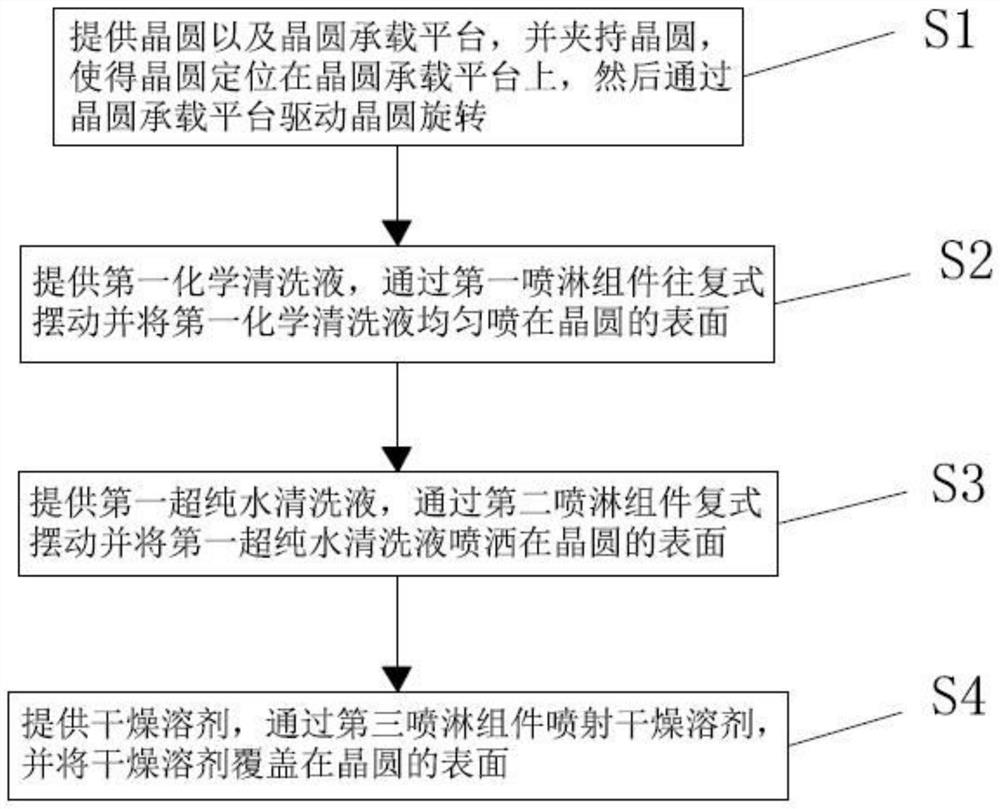

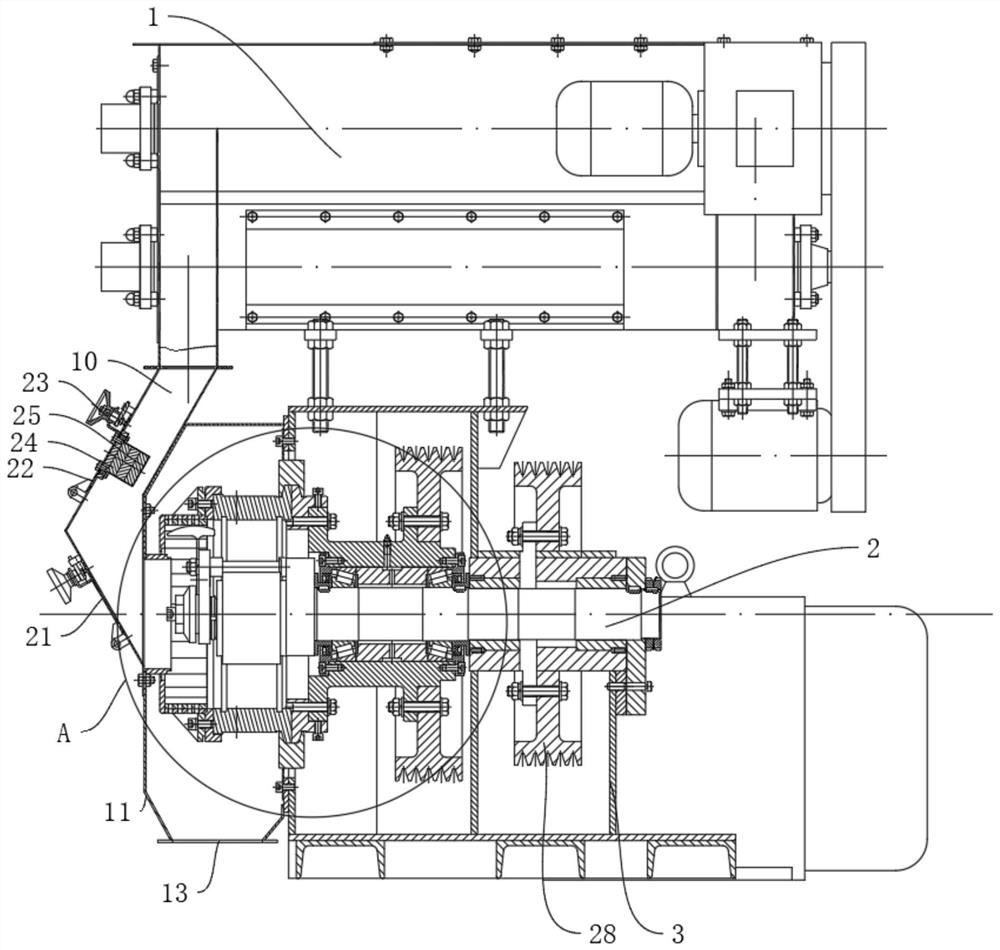

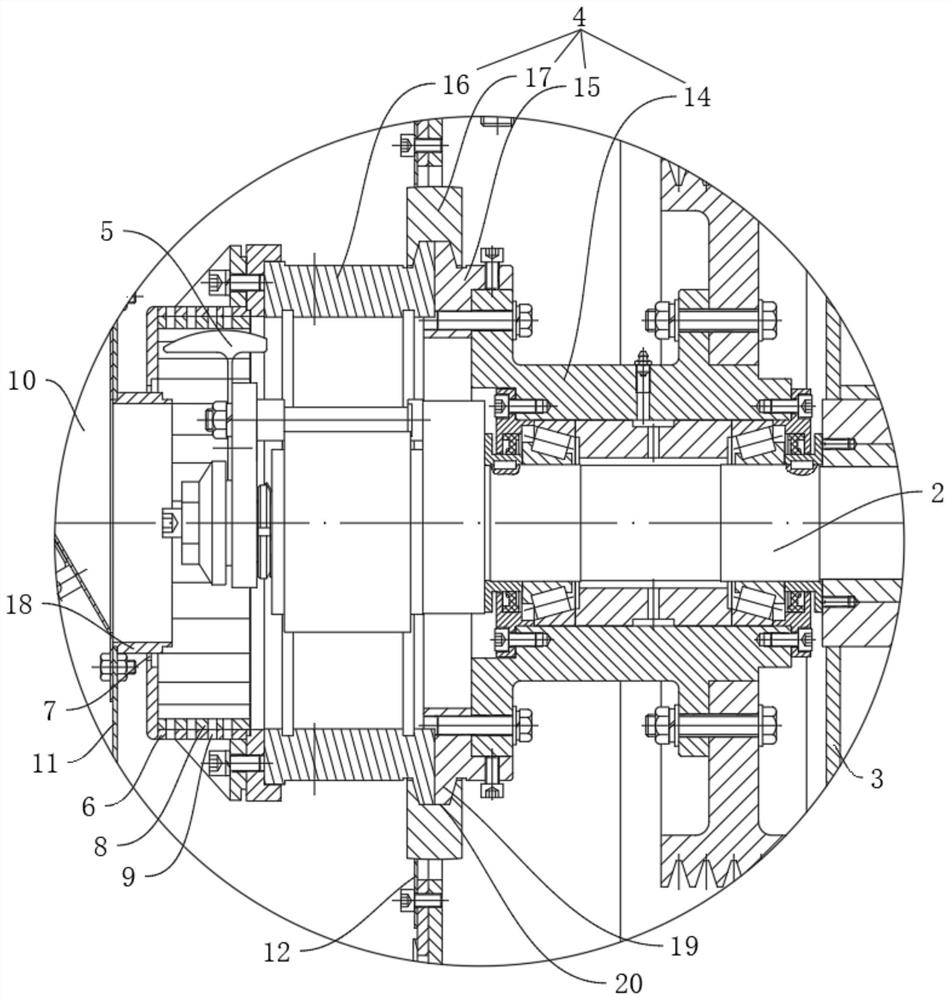

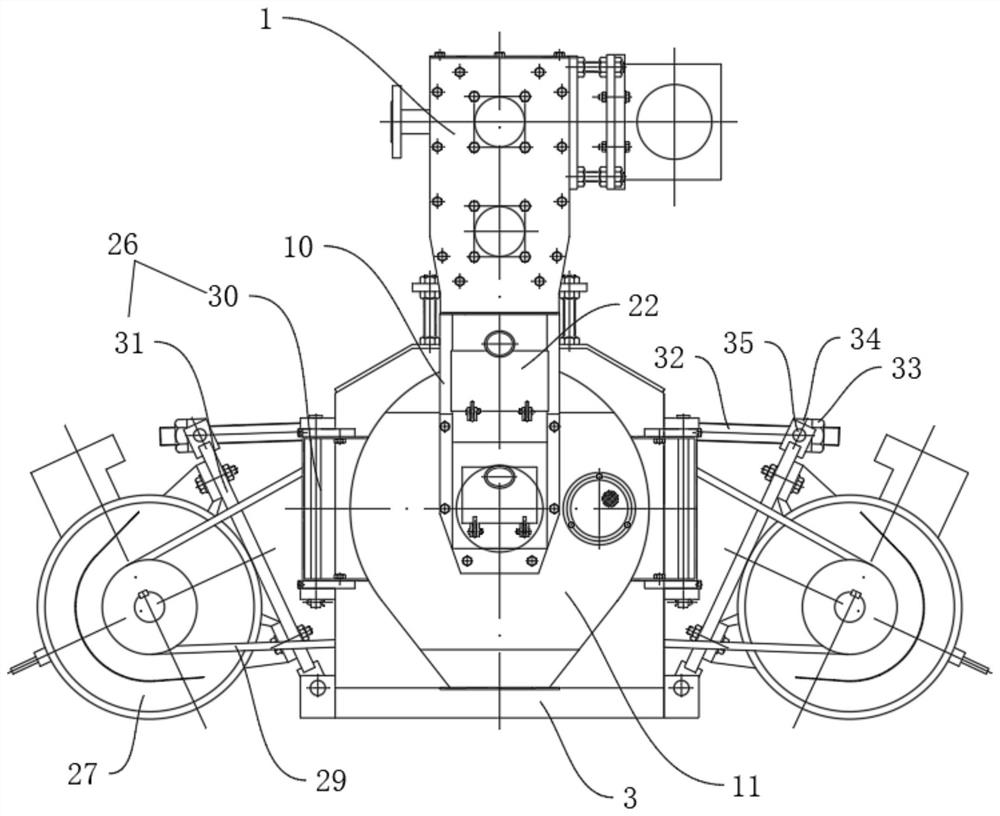

Control method for effectively achieving rotation and spraying in single wafer cleaning process

ActiveCN114405909AImprove adhesionThorough responseFinal product manufactureSemiconductor/solid-state device manufacturingSurface reactionMetallurgy

Owner:ULTRON SEMICON (SHANGHAI) CO LTD

Ultrapure water ion column waste crusher

Owner:上海乐枫生物科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap