Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7 results about "Radical polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

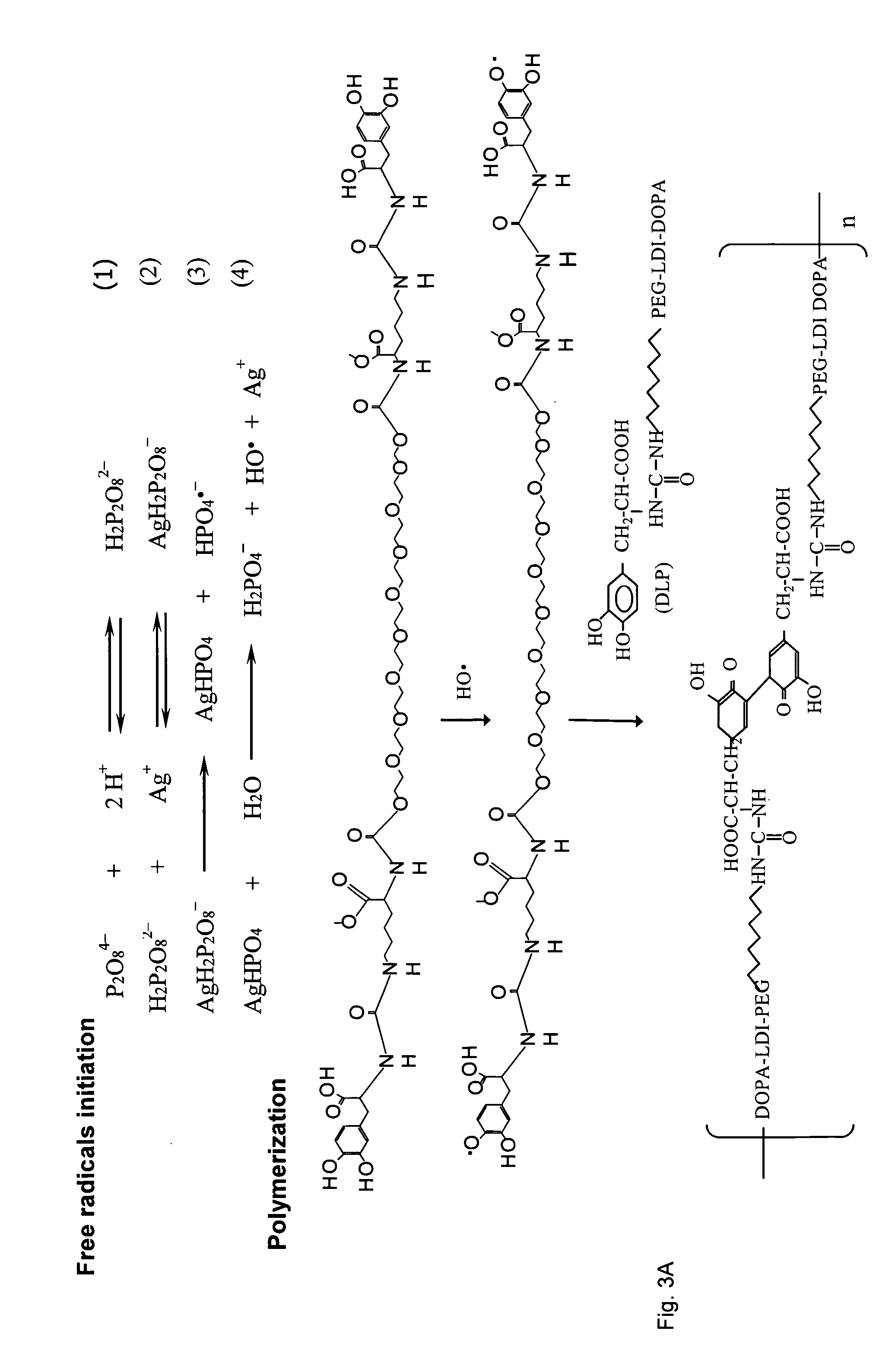

Free-radical polymerization (FRP) is a method of polymerization by which a polymer forms by the successive addition of free-radical building blocks. Free radicals can be formed by a number of different mechanisms, usually involving separate initiator molecules. Following its generation, the initiating free radical adds (nonradical) monomer units, thereby growing the polymer chain.

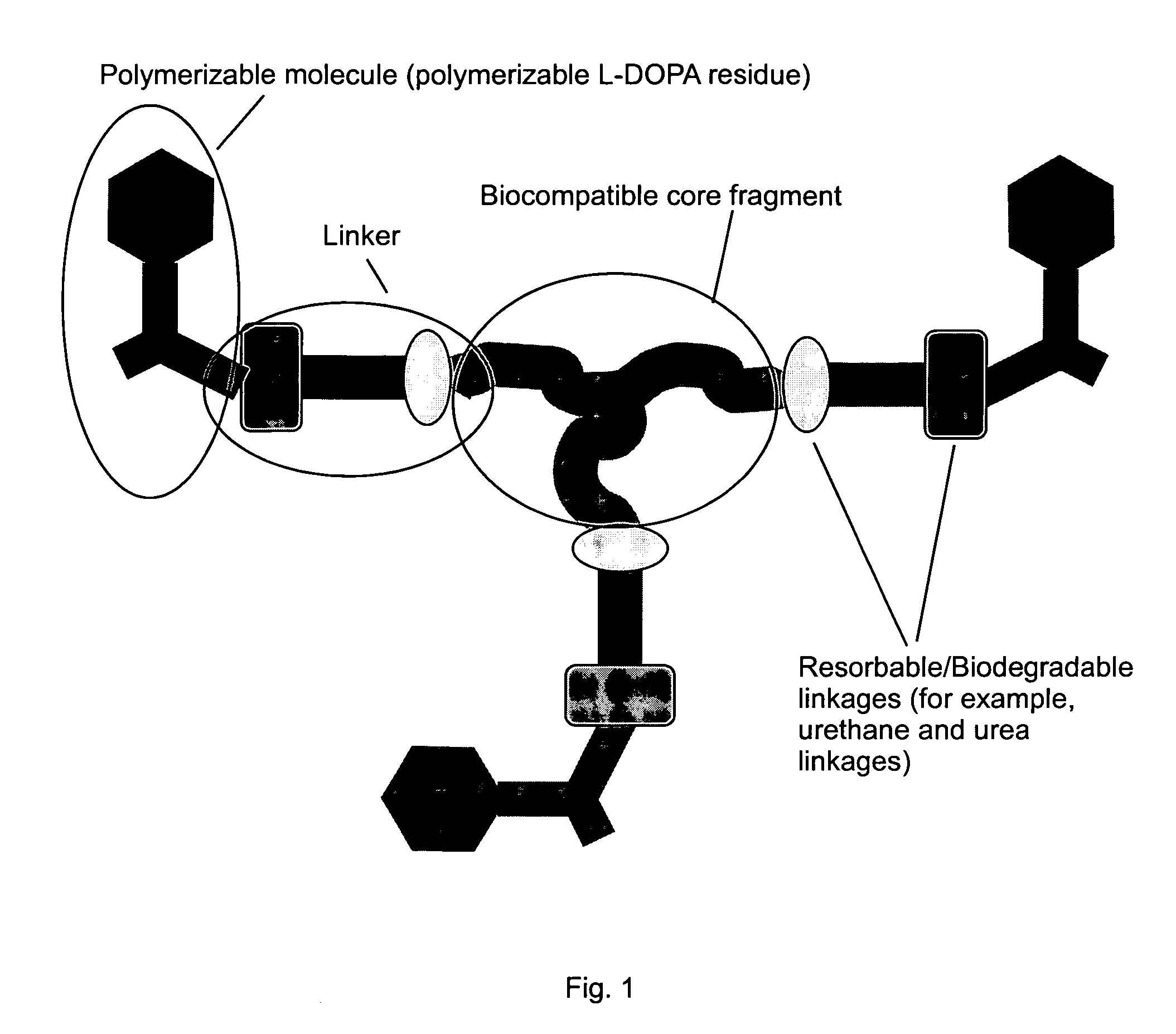

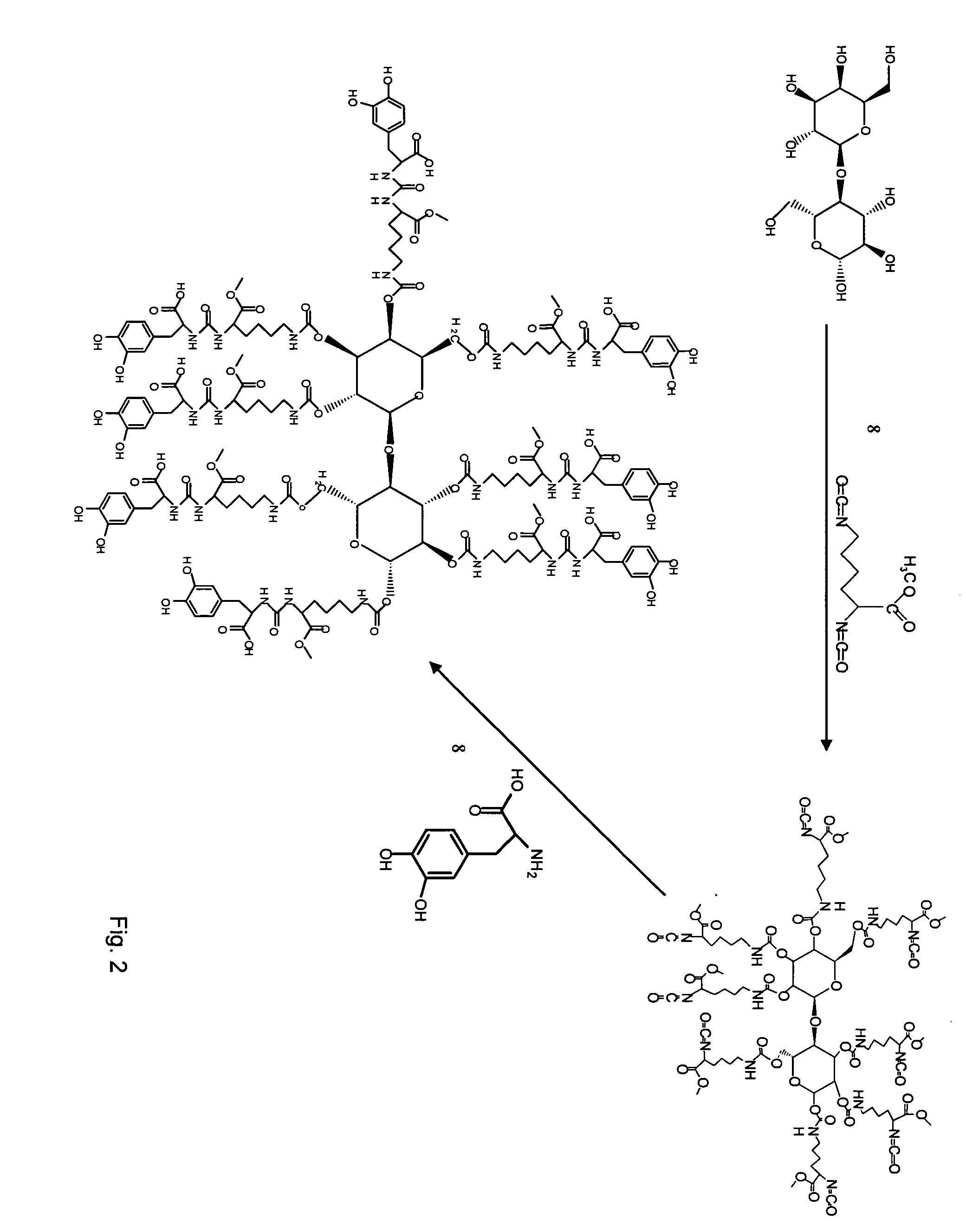

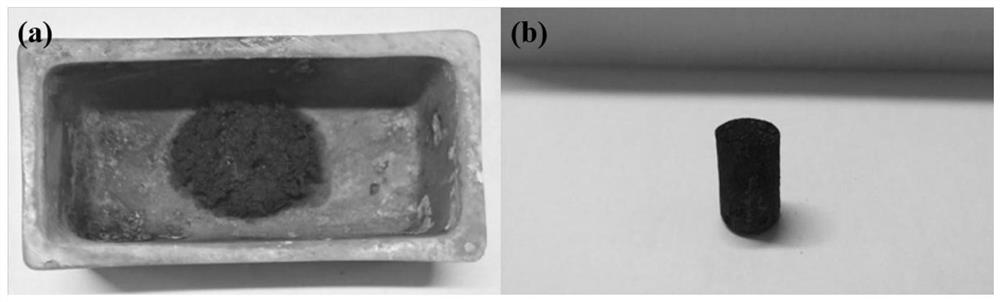

Wound healing polymeric networks

Owner:UNIVERSITY OF PITTSBURGH

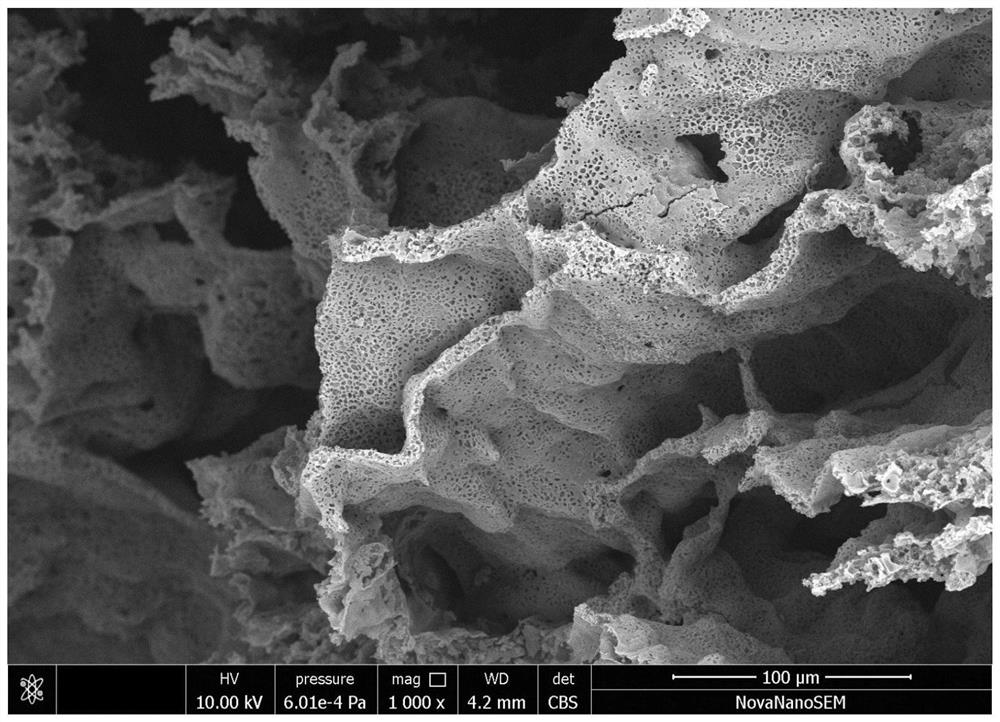

Preparation method of self-supporting porous carbon electrode material

Owner:YANCHENG INST OF TECH

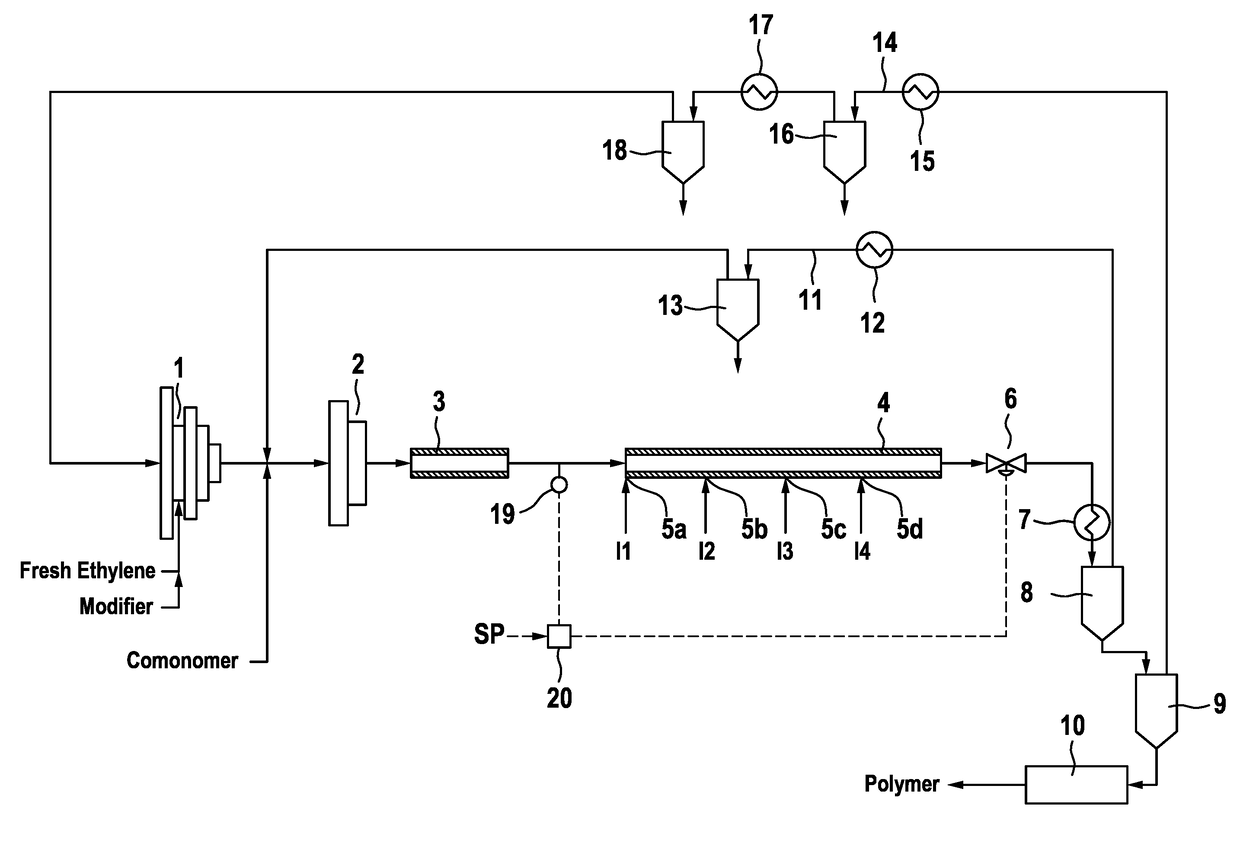

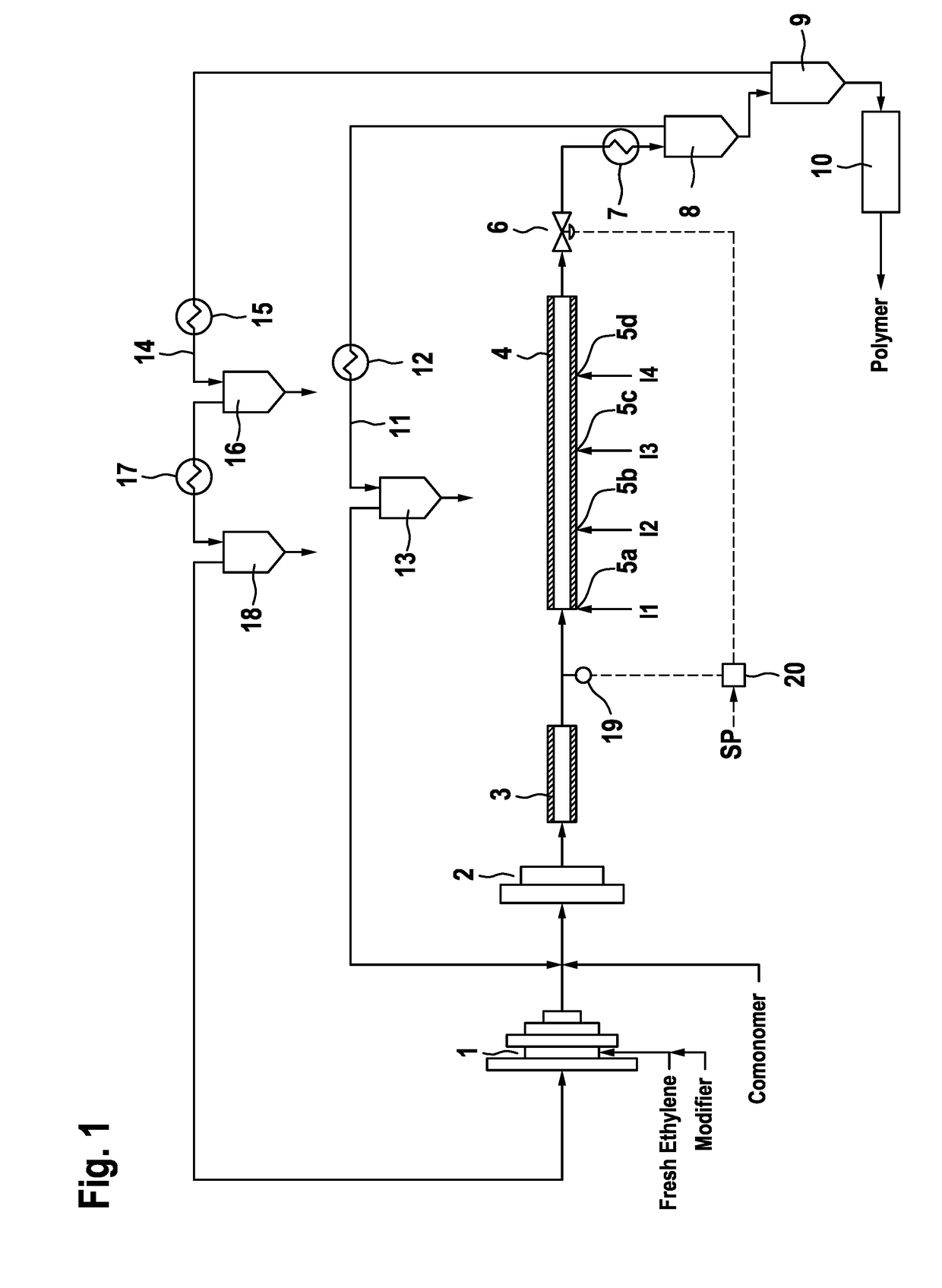

High-pressure polymerization process of ethylenically unsaturated monomers

ActiveUS20180030160A1Process control/regulationFluid pressure measurementDecreased pressureControl valves

Owner:BASELL POLYOLEFINE GMBH

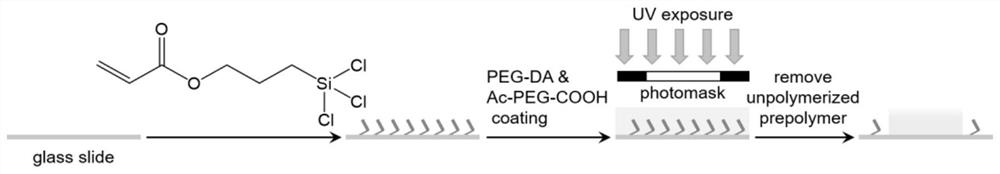

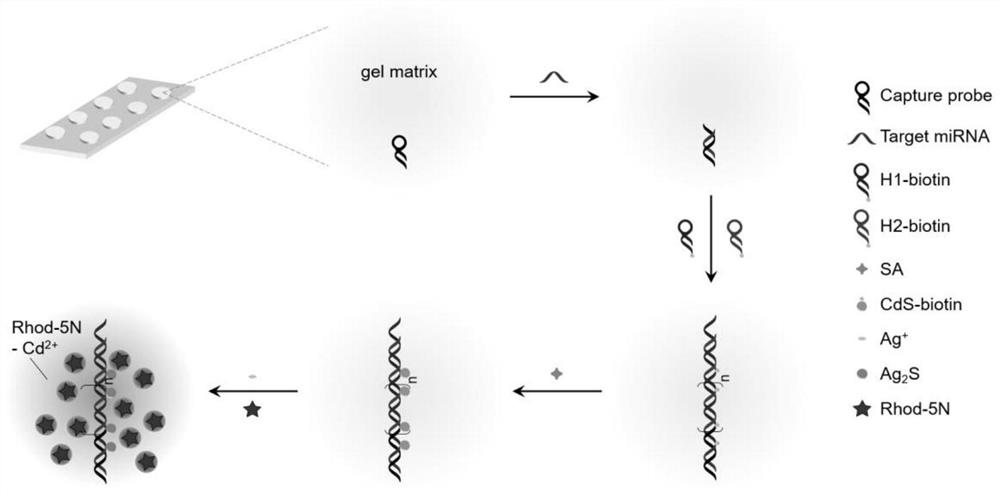

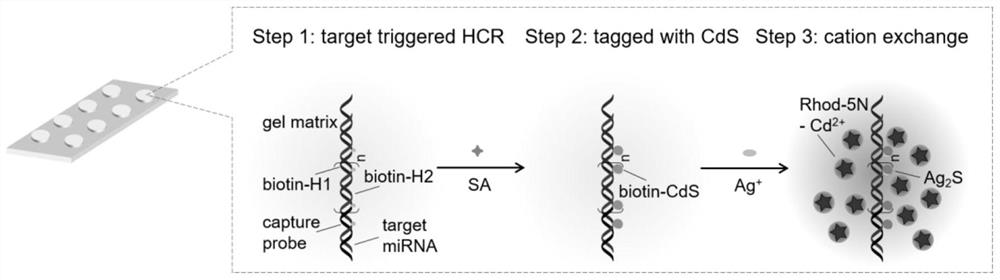

Fluorescence analysis method based on HCR and cation exchange reaction of hydrogel

ActiveCN111735801AGood resistance to non-specific adsorptionAchieving specific and sensitive detectionMicrobiological testing/measurementFluorescence/phosphorescenceCation exchange reactionUltraviolet lights

Owner:NANJING UNIV

Preparation method of polyacrylamide reverse-phase emulsion

Owner:SHANDONG UNIV

Method for preparing vinyl monomer polymer by using cobalt diphosphine dihalide as catalyst

The invention relates to a process for utilizing catalyst such as diphosphonic dihalide cobalt to prepare vinyl monomer polymer. The catalyst of the invention is a compound such as diphosphonic dihalide cobalt which has the structure of the general formula (I) (II). The process for preparing vinyl monomer polymer of the invention comprises leading the vinyl monomer to have a polymerization reaction in organic solvent under the protecting of the catalyst (I) or (II), initiating agent and inactive gas. The mole ratio of the initiating agent and the catalyst is 0.5-50, the temperature of polymerization reaction is 60-90 DEG C, the general vinyl monomer can have free radical polymerization reaction which can be controlled to get polymers whose molecular weight is between the scope of 5000-100000, and the molecular weight can be controlled and the distribution thereof is narrow, and get the polymer whose block, graft and super graft can be controlled. The invention has a certain prospect of industrialization application.

Owner:NANKAI UNIV

Free radical polymerization-based preparation method of water-based coating

The invention discloses a free radical polymerization-based preparation method of a water-based coating. The preparation method comprises the following steps: (1) obtaining liquid illegal cooking oilby adopting a solid-liquid separation technology, then washing the liquid illegal cooking oil respectively with deionized water and a strong-polarity organic solvent in which the illegal cooking oil cannot be dissolved, and finally adding a decoloring agent till the illegal cooking oil is faint yellow, transparent and clear liquid, thus obtaining purified illegal cooking oil; and (2) adding the deionized water, a pH modifier, an emulsifier, a dispersant, an initiator, the purified illegal cooking oil and acrylic ester into a reaction kettle in sequence according to a weight ratio of 90:(0.15-0.23):(1.6-2.2):(0.1-0.5):(0.5-1.5):(43-54):(40-60), and stirring for 10 to 14 min at a stirring speed of 300-800 r / min, thus obtaining illegal cooking oil emulsion. According to the free radical polymerization-based preparation method disclosed by the invention, instable unsaturated oil with low molecular weight is subjected to free radical polymerization to form stable copolymer resin water emulsion with high polymerization degree, so that the prepared water-based coating is high in film forming property and adhesive force and can be widely applied to the field of decoration of a building external wall and the like.

Owner:CHENGDU MITRE NEW MSTAR TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap