Novel slitting roller

A rolling shear machine, a new type of technology, is applied in the direction of shearing machine equipment, shearing devices, metal processing equipment, etc., and can solve problems such as difficult cutting of steel strips, plastic deformation of steel strips, and large gap between hob blades, etc., to achieve improvement Cutting effect and passability, easy disassembly and installation, easy replacement and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] The present invention will be further described in detail below through specific implementation examples in conjunction with the accompanying drawings.

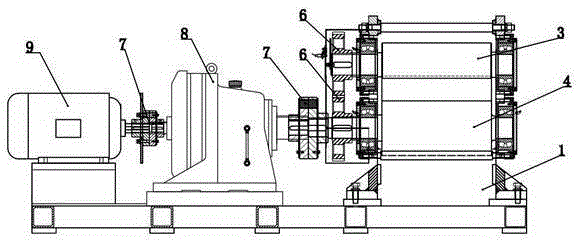

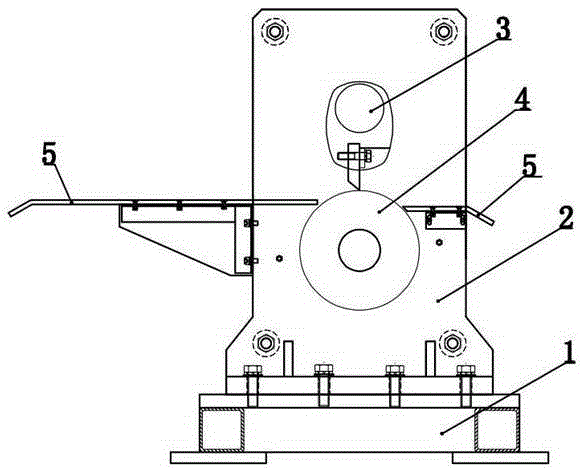

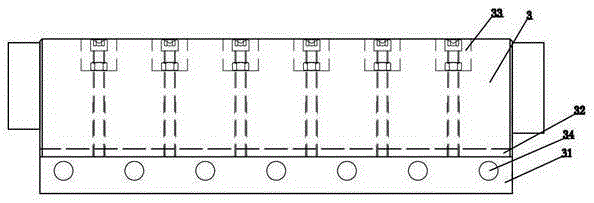

[0029] figure 1 , figure 2 , image 3 with Figure 4 Shows a new type of rolling shear provided by the present invention, including an eccentric roller 3 and a roller 4 arranged up and down, the eccentric roller 3 and the roller 4 are installed on the mounting frame 2, and the mounting frame 2 is installed on the base 1 The eccentric roller 3 and the roller 4 are arranged to rotate towards each other; the eccentric roller 3 is provided with a notch 31, and the blade 12 is fixedly installed at the notch 31. The relative rotation of the eccentric roller 3 and the roller 4 can guide the plate Moving forward, and when the blade 12 and the roller 4 on the eccentric roller 3 rotate to the cutting position, the blade 12 directly cuts the steel strip, and the device cuts the plate with a thickness of 10 mm or more.

[0030] Preferab

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap