Fit component mechanism of latch, bolt and steel structure

A technology of steel structure and locking parts, which is applied in the direction of building components, building structures, walls, etc., can solve the problems of easy retraction of the screw and poor anti-retraction effect, and achieve firm and convenient cooperation, perfect integrity, and structural design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0024] Example.

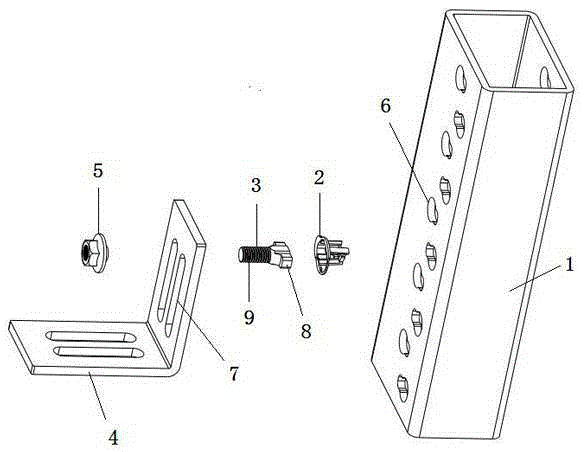

[0025] see Figure 1 to Figure 4 In this embodiment, the lock, bolt and steel structure matching assembly mechanism mainly includes a closed rectangular tube 1, a lock piece 2, a bolt body 3, a connecting piece 4 and a nut 5.

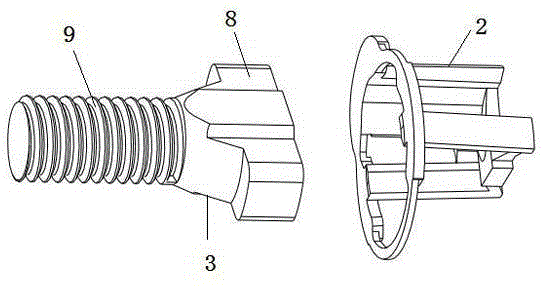

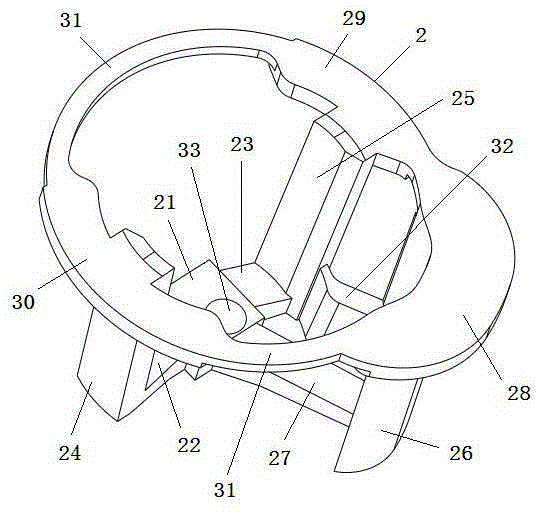

[0026] The bolt body 3 and the nut 5 in this embodiment match each other, the bolt body 3 includes a bolt head 8 and a screw rod 9 connected to each other, one end of the bolt body 3 cooperates with the nut 5 through the connecting piece 4, and the other end of the bolt body 3 passes through The locking piece cooperates with the closed rectangular tube 1 , the bolt body 3 is a T-shaped bolt body 3 , the bolt body 3 is an integral structure, and the internal thread of the nut 5

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap