Method for calibrating low-dropout linear voltage stabilizer

A low dropout linear, voltage regulator technology, applied in instruments, regulating electrical variables, control/regulating systems, etc., can solve problems such as inability to read trimming values correctly, inability to work normally, and improve chip yield and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

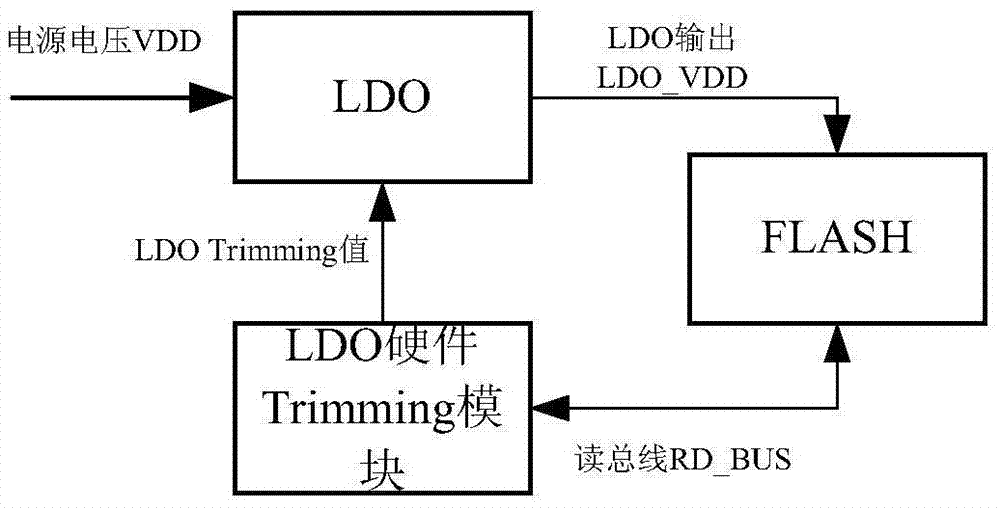

[0033] figure 1 Shown is the hardware circuit structure included in the LDO hardware calibration implemented in the present invention. It mainly includes LDO, LDO hardware Trimming module and storage unit flash. The functions of each circuit unit are as follows:

[0034] LDO: When the power supply voltage VDD is connected, the LDO output voltage LDO_VDD for Flash is generated according to the trimming value sent by the LDO hardware trimming module.

[0035] LDO hardware trimming module: read the LDO key and LDOtrimming value stored in Flash, and provide the LDOTrimming value to LDO, thereby changin

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap