Non-circular gear spatial spherical 4R shedding mechanism

A technology of non-circular gears and shedding mechanisms, which is applied in cam shedding mechanisms, textiles, textiles, and papermaking, and can solve problems such as unfavorable weaving of wide-width fabrics, warp breakage, or other fabric defects, so as to expand variety adaptability, prolong Weft insertion time, the effect of increasing the approximate dwell time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

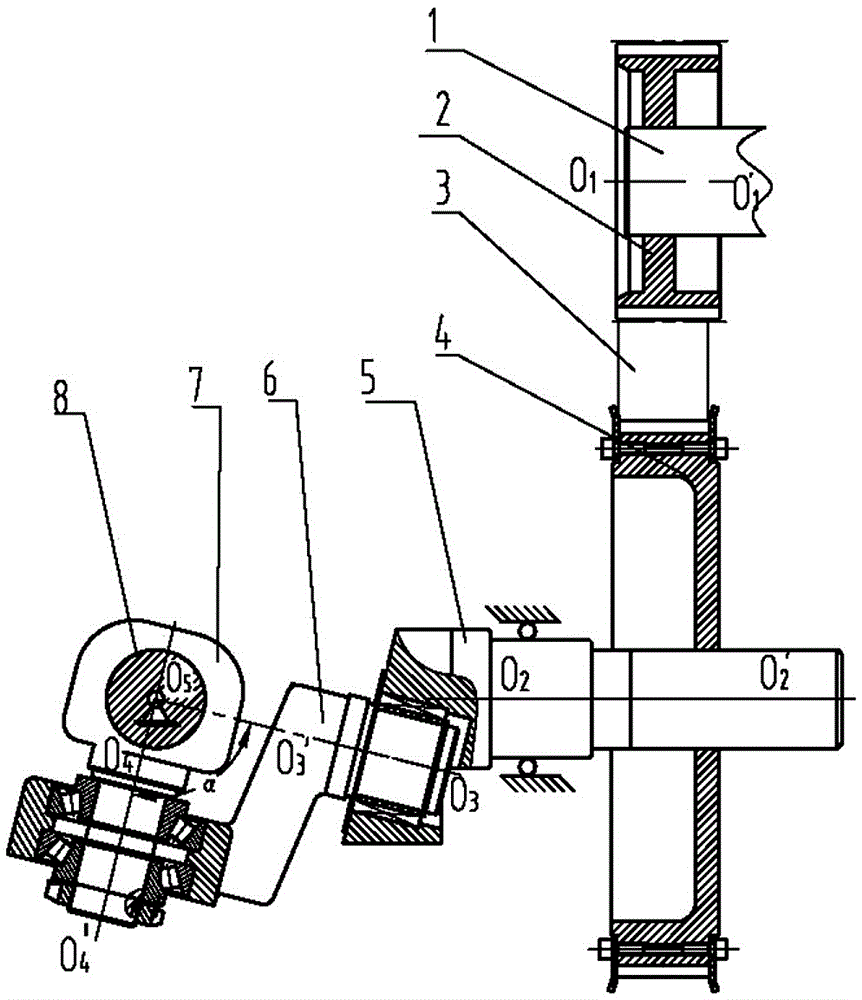

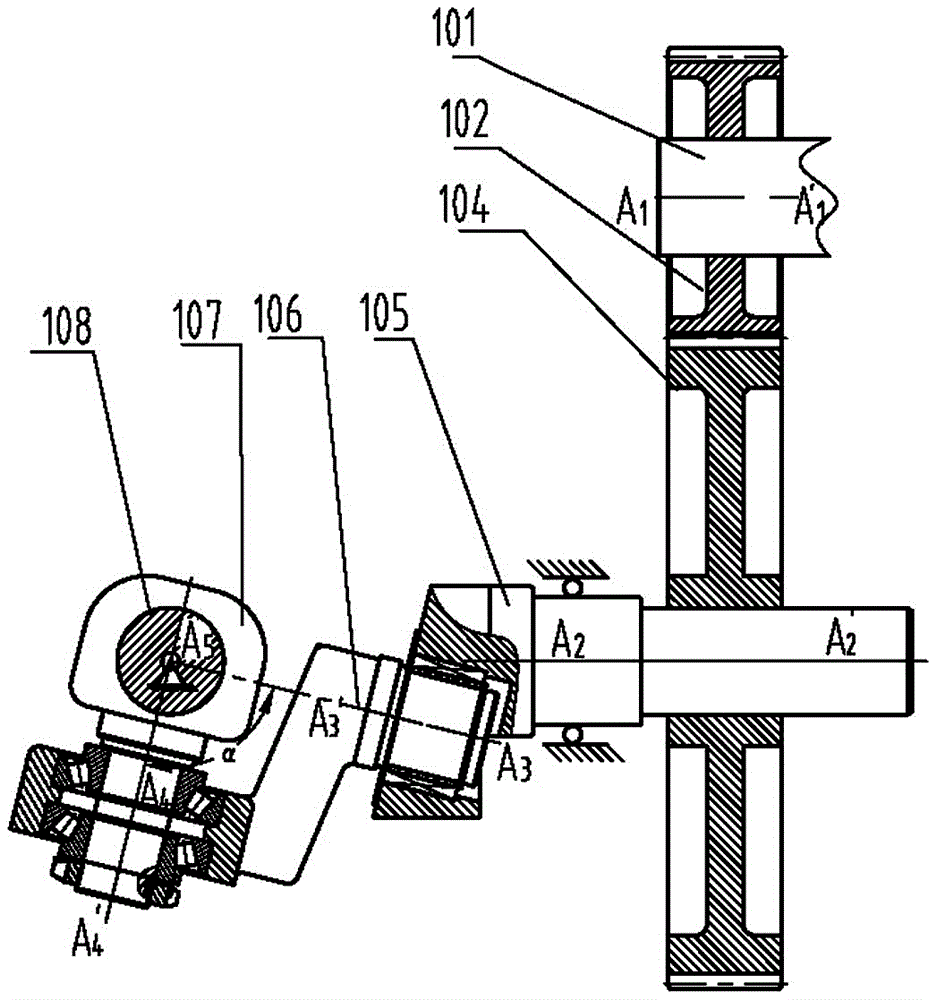

[0011] The present invention will be described in detail below in conjunction with accompanying drawing: figure 2 As shown, a non-circular gear space spherical 4R opening mechanism according to the present invention includes a small gear 102 fixed on the main shaft 101, the main shaft 101 is connected with the frame through a bearing, the large gear 104 is fixed on the crankshaft 105, and the crankshaft 105 is connected to the frame through bearings, the large gear 104 is directly meshed with the pinion 102, and the teeth of the large gear 104 and the small gear 103 are non-circularly distributed, and the meshing pitch line of the two is non-circular; One end of the space connecting rod 106 is connected to the crankshaft 105 through a bearing, and the other end is connected to the swing arm 107 through a tapered roller bearing; the axis A of the two bearings on the space connecting rod 106 3 A 3 ‘ 、A 4 A 4 ‘ The included angle α is 90°; the swing arm 107 is fixedly connecte

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap