Bundling machine control system of joint harvesting bundling machine

A technology of control system and baler, which is applied in the direction of baler, harvester, agricultural machinery and implements, etc., can solve the problems of affecting service life, performance degradation and change of combined harvesting and baling machine, and achieves easy judgment, The effect of improving work efficiency and adaptability to the work environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

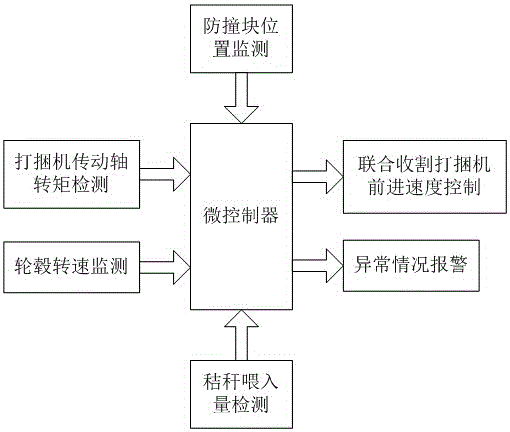

[0025] like figure 1 As shown, the baler control system of the combine harvester baler disclosed in the present invention includes a wheel hub speed detection device, a baler drive shaft torque detection device, a straw feeding amount detection device, a safety bolt, an anti-collision device, Anti-collision block position monitoring device, combine harvester baler forward speed control device, baler abnormality alarm device and microcontroller.

[0026] The wheel hub speed detection device is a non-contact speed sensor composed of a magnet and a Hall sensor, which is used to detect the rotation speed of the baler drive shaft;

[0027] The torque detection device of the drive shaft of the baler uses two disc gratings, a light source and a photosensitive element to form a photoelectric torque sensor, which is used to measure the torque of the drive shaft of the baler;

[0028] The straw feeding amount detection device is composed of a pressure sensor, which is used to measure the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap