Engine bifurcated tail spray pipe weld joint laser shock peening and correcting method and device

A laser shock strengthening and laser shock technology, which is applied in the field of laser shock strengthening and shape correction of the welding seam of the engine bifurcated tail nozzle, can solve the problems such as the deformation of the tail nozzle, and achieve the effect of improving strength, ensuring stability and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

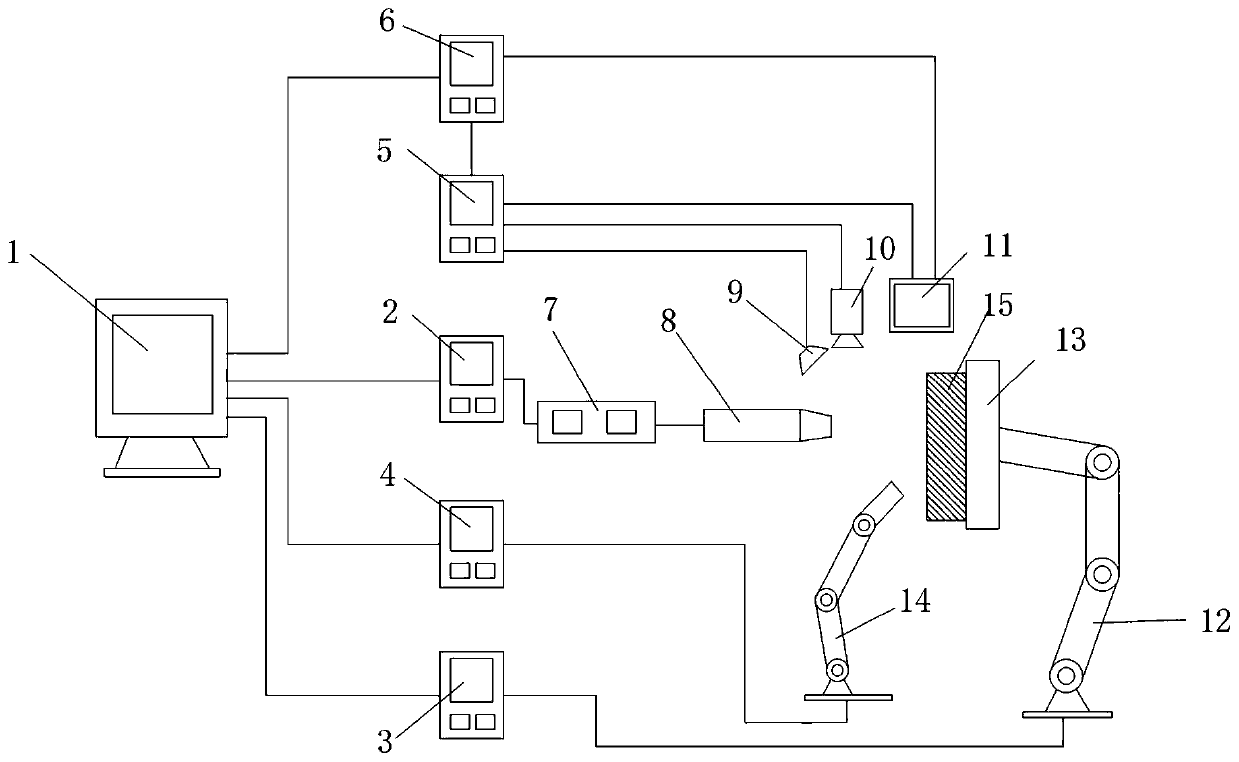

[0046] Such as figure 2 As shown, this embodiment discloses a device for laser shock strengthening and shape correction of the welding seam of the engine bifurcated tail nozzle. The device mainly includes a complete machine control system 1, a laser 7, a laser control system 2, and a laser shock strengthening unit 8. Auxiliary lighting LED lamp group 9. Special tooling fixture for tail nozzle 13. Clamping robot 12. Clamping robot control system 3. Watering robot 14. Watering robot control system 4. Optical measuring instrument 10. Optical equipment control system 5. Three-dimensional profile scanner 11, and data acquisition system 6;

[0047] Specifically, the whole machine control system 1 is respectively connected with the laser control system 2, the clamping robot control system 3, the water coating robot control system 4 and the data acquisition system 6, and drives each system to work together in an orderly manner; the optical device control System 5 is respectively connec

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap