A sealing zipper

A technology for sealing zippers and zipper teeth, applied in the field of zippers, can solve the problems of easy wear and tear, inconvenient production, abruptness, etc., and achieve the effects of not easy to crack or leak, labor-saving during the pulling and closing process, and high commercial utility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

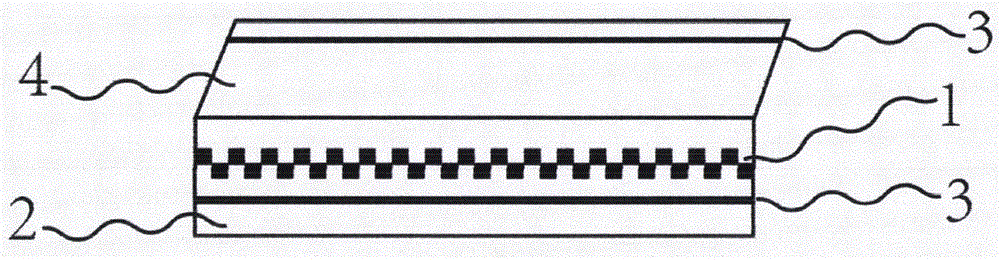

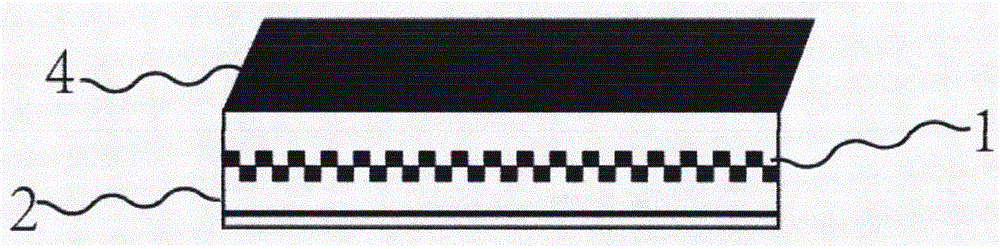

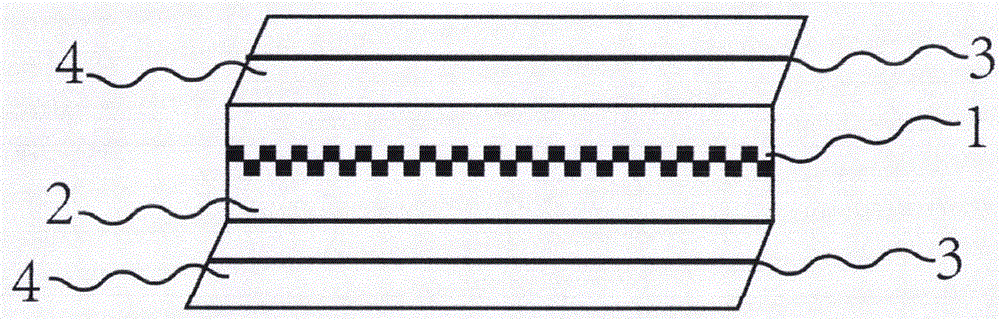

[0033] An airtight zipper such as figure 1 As shown, the airtight zipper includes a base cloth 3, a first zipper element 1, a second zipper element 2 and a zipper puller, and a first mask 6 is arranged on the base cloth 3 on the side of the first zipper element 1. The masking sheet 6 is seamlessly joined with the base fabric 3 , and the first magnetic strip 4 is provided on the first masking sheet 6 along the opening and closing direction of the first zipper element 1 and the second zipper element 2 .

[0034] A second magnetic strip 5 is provided at a position corresponding to the first magnetic strip 4 on one side of the second zipper element 2, so that when the first magnetic strip 4 and the second magnetic strip 5 are fastened together, the first mask 6 covers the The closed first zipper element 1 and the second zipper element 2 make the accommodating chamber using the sealed zipper form a sealed space.

[0035] The second magnetic strip 5 can be arranged on the base cloth

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap