Honeycomb-type dielectric barrier discharge plasma propelling device

A dielectric barrier discharge and plasma technology is applied in the field of plasma propulsion devices and airships. The effect of improving energy efficiency and lowering manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

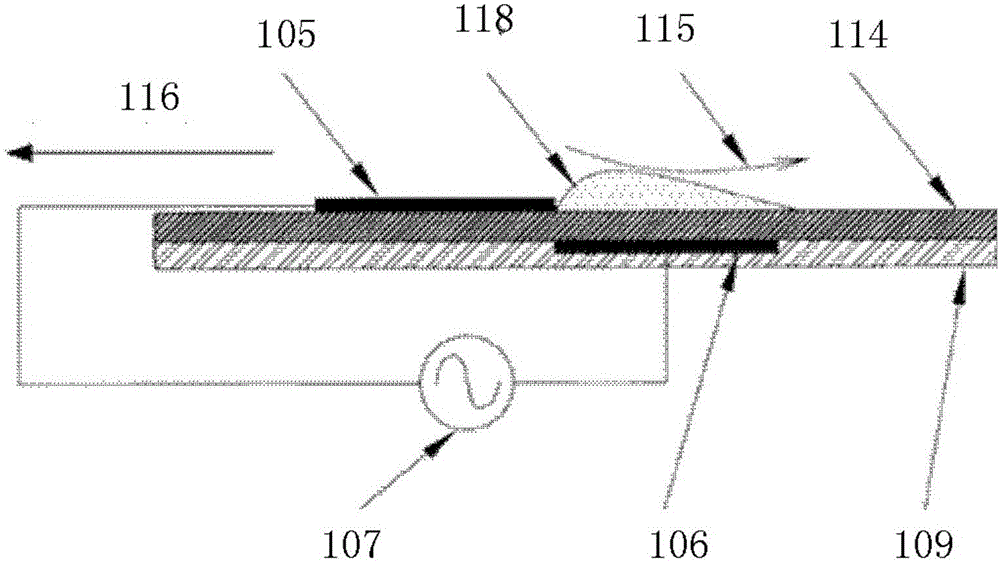

[0042] see figure 1 , figure 1 It is a schematic diagram of the working principle of the dielectric barrier discharge plasma excitation structure. Among them, the high-voltage electrodes 105 and the ground electrodes 106 are alternately arranged on both sides of the insulating medium 114, and the high-voltage alternating current is provided by the high-voltage power supply 107. After the high-voltage electrodes 105 and the ground electrodes 106 are connected to the high-voltage electricity, the fluid in the vicinity is ionized to generate plasma 118. 118 can induce flow, and at the same time generate a thrust opposite to the induced flow direction 115, so as to realize the excitation of the reaction force direction 116. At

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap