Reciprocation pump reversing mechanism with overload protection

A technology of overload protection and reversing mechanism, which is applied in the direction of pump control, mechanical equipment, machine/engine, etc., can solve the problems of low working efficiency of equipment, low life of reversing mechanism, disordered reversing, etc., and achieve simple structure and increased stability Effects of improving performance, safety performance, and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

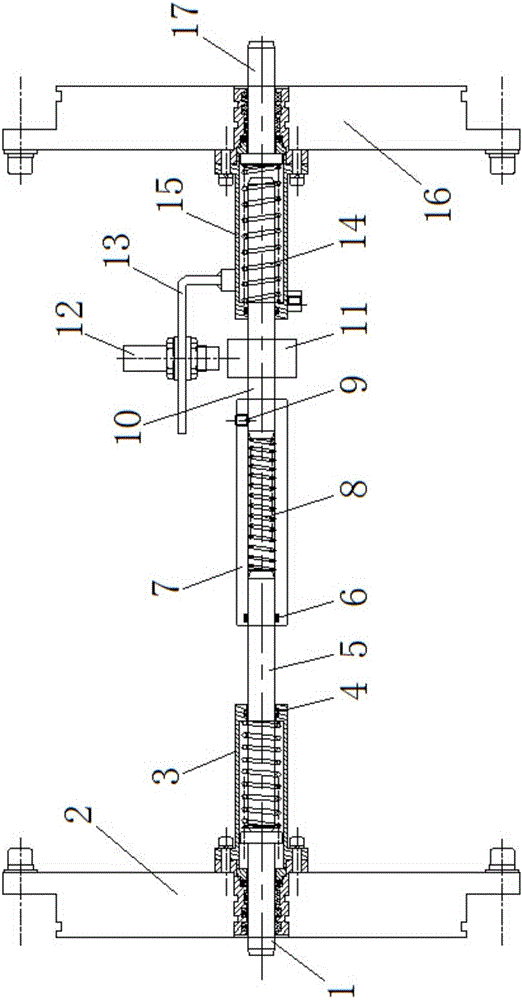

[0017] As shown in Figure 1, a reciprocating pump reversing mechanism with overload protection includes a left working cylinder end cover 2 and a right working cylinder end cover 16; the reversing mechanism consists of a push rod, an induction push rod, a sliding sleeve, and an overload protection The sleeve 7, the induction block 11 and the proximity switch 12 are connected to form; the push rod includes a left push rod 1 and a right push rod 17, and the left push rod 1 is slidably connected in the left working cylinder end cover 2, and the right push rod 17 Slidingly connected to the end cover 16 of the right working cylinder; the sliding sleeve includes a left sliding sleeve 3 and a right sliding sleeve 15, the left sliding sleeve 3 is fixedly connected with the left working cylinder end cover 2, and the right sliding sleeve 15 is fixed to the right working cylinder end cove

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap