Production method for expanded graphite

A technology of expanded graphite and a production method, which is applied in the chemical industry, can solve the problems of low production efficiency, low heat utilization rate of the furnace cavity, long time for heating up and cooling down of the puffed muffle furnace, etc., and achieve high energy utilization rate and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

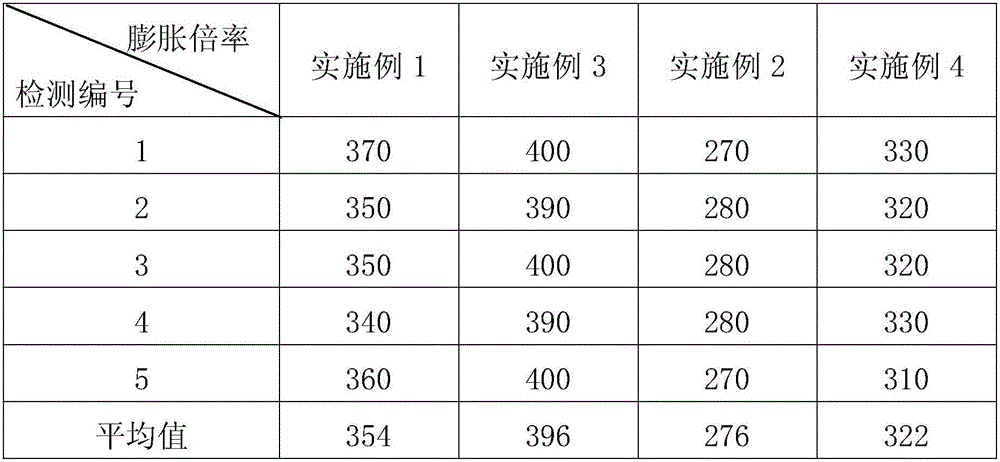

[0020] Example 1: Preparation of expanded graphite by traditional expanded muffle furnace

[0021] 1) Take 15g of intercalated graphite with a purity of 98.5% through an 80 mesh sieve, spread it on the tray, and then quickly put it into the muffle furnace heated to 850℃, close the furnace door, and load the material after 5 seconds Disk removal

[0022] 2) Pour the expanded graphite in the tray into the measuring cup, repeat the measurement of the volume expansion ratio for 5 times, and take the average value. The detection standard of the volume expansion ratio is in accordance with GB10698-89 (the same below).

Example Embodiment

[0023] Example 2: Preparation of expanded graphite by traditional expanded muffle furnace

[0024] 3) Take 15g of intercalated graphite with a purity of 99% passing through a 100 mesh sieve, spread it in the tray, and then quickly put it into the muffle furnace heated to 1000℃, close the furnace door, and load the material after 5 seconds Disk removal

[0025] 4) Pour the expanded graphite in the receiving tray into the measuring cup, repeat the measurement of the volume expansion ratio for 5 times, and take the average value.

Example Embodiment

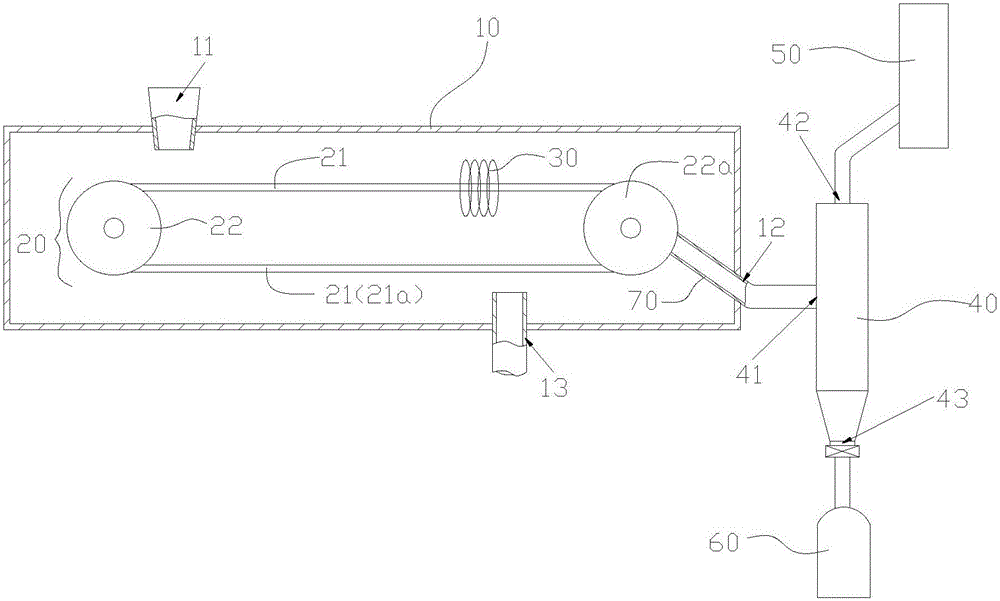

[0026] Example 3: The production method of the present invention prepares expanded graphite

[0027] 1) Take 15g of intercalated graphite with a purity of 98.5% through an 80-mesh sieve, and spread it evenly on the conveyor belt 20 from the inlet 11 by a swinging sieve. The conveyor belt 20 is driven forward to high frequency at a rate of 3cm / s. The induction coil is heated instantaneously, and the entire cavity of the box 10 is passed through the air inlet 13 with nitrogen as a protective atmosphere, and is convectively cooled with the conveyor belt 20. The effective heating length of the heating zone of the conveyor belt 20 is 15 cm. The induction frequency of the high-frequency induction coil is 120MHz, and the heating rate is 850℃ / s, which instantly raises the surface temperature of the conveyor belt 20 from room temperature to 850℃;

[0028] 2) The heated and expanded graphite enters the cyclone collector 40 through the discharge port 12 for gas-solid separation, and the soli

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap