Method for detecting identification code tagging quality of large-breadth printing material

A quality inspection method and technology for printing materials, applied to record carriers, instruments, data processing applications, etc. used in machines, can solve the problems of QR code storage loss, loss of double-sided coding, etc., so as to improve production efficiency and avoid waste products. , cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

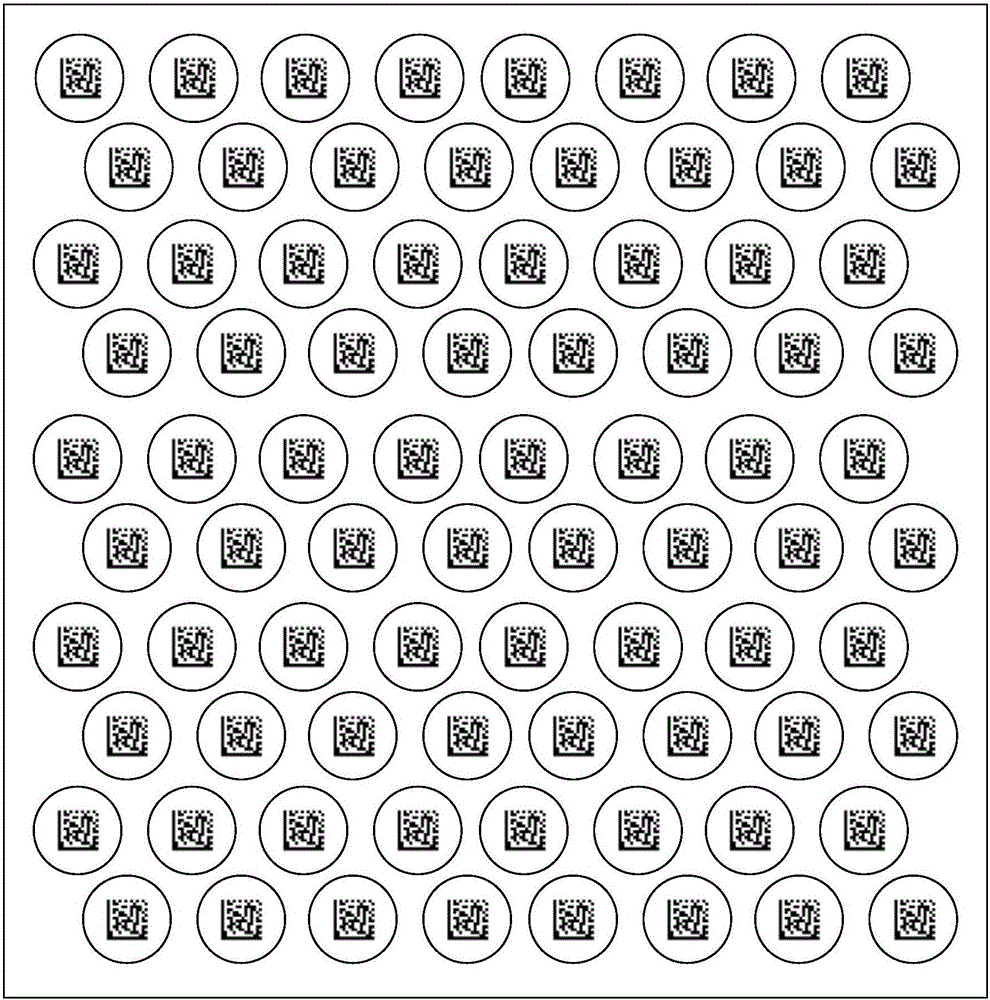

[0033] In order to meet the production efficiency requirements of large-scale industrial production, identification coded products such as crown caps and cigarette packaging boxes are printed on large-format materials by special coding equipment such as inkjet printers and laser engraving machines, such as production The surface of the large iron sheet used for the crown cover, the large sheet of paper used in the production of cigarette packaging boxes, etc. are printed or laser engraved (referred to as spray engraved) with multiple identification codes in batches, and then cut and processed. figure 1 It is an example diagram of batch printing multiple QR codes on the surface of large-format printing materials.

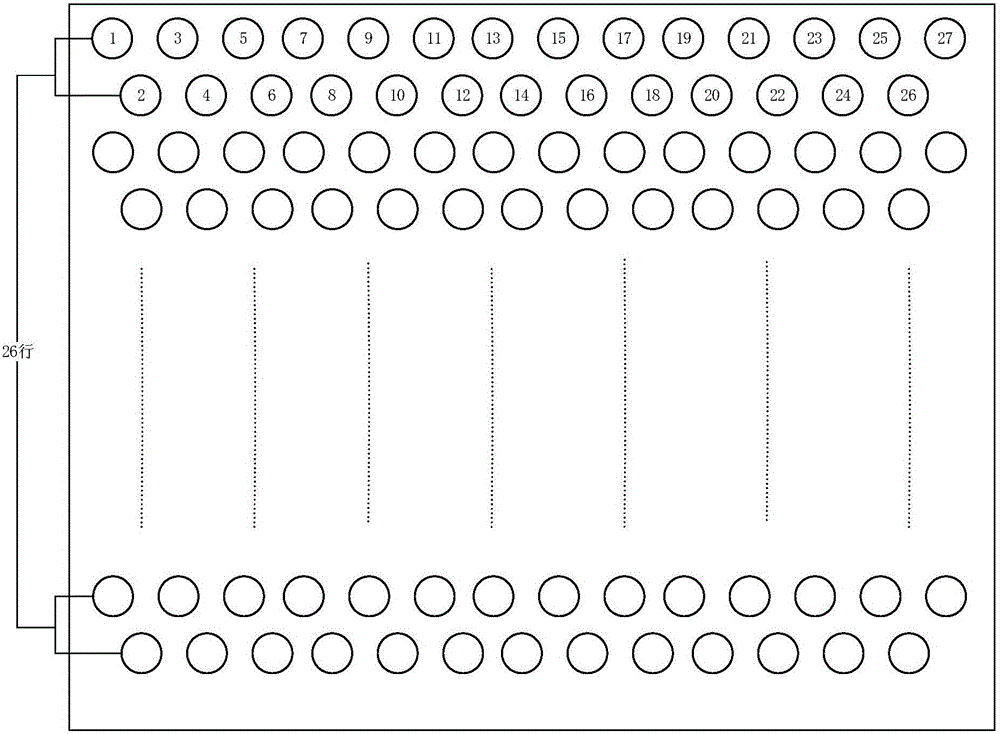

[0034] Marking codes on large format printed materials often requires multiple printers or laser eng

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap