Method for online monitoring resistance change of metal soldered joint

A technology for brazing joints and welding joints, applied in the field of non-destructive evaluation, can solve the problems of low detection accuracy of the brazing rate and cannot reflect the welding conditions of brazing joints well, and achieves intuitive and clear measurement results, simple results, and easy operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0042] Example 1

[0043] In this embodiment, 304 stainless steel is selected as the brazing base material, and its size is 10mm×80mm×1mm. AgCuTi metal foil (melting point: 800°C to 820°C) is selected as the solder.

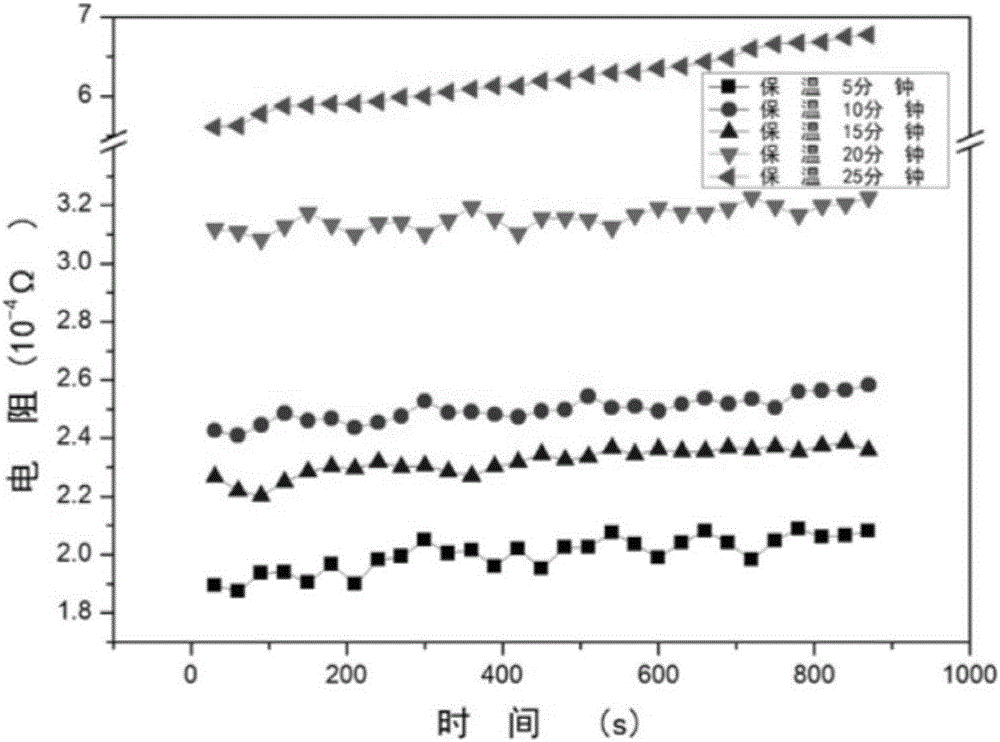

[0044] When brazing, the 304 stainless steel base metal is lapped along the length direction, and the lap length is 10mm. Before welding, use No. 1000 sandpaper to smooth the surface to be welded, and then use alcohol to ultrasonically clean it for 15 minutes and dry it. Assemble the prepared materials in the form of 304 stainless steel / Ag-Cu-Ti / 304 stainless steel. The test was carried out in a vacuum diffusion welding furnace with a vacuum of 1.0×10 -2 -1.0×10 - 3 Pa. The heating temperature is 870°C, the holding time is 20-50min, and the connection pressure is 0.05MPa.

[0045] The brazing filler metal AgCuTi and 304 stainless steel vacuum brazing process is as follows: heating at 10°C / min to 820°C, holding for 30 minutes, then continuing to heat at

Example Embodiment

[0054] Example 2

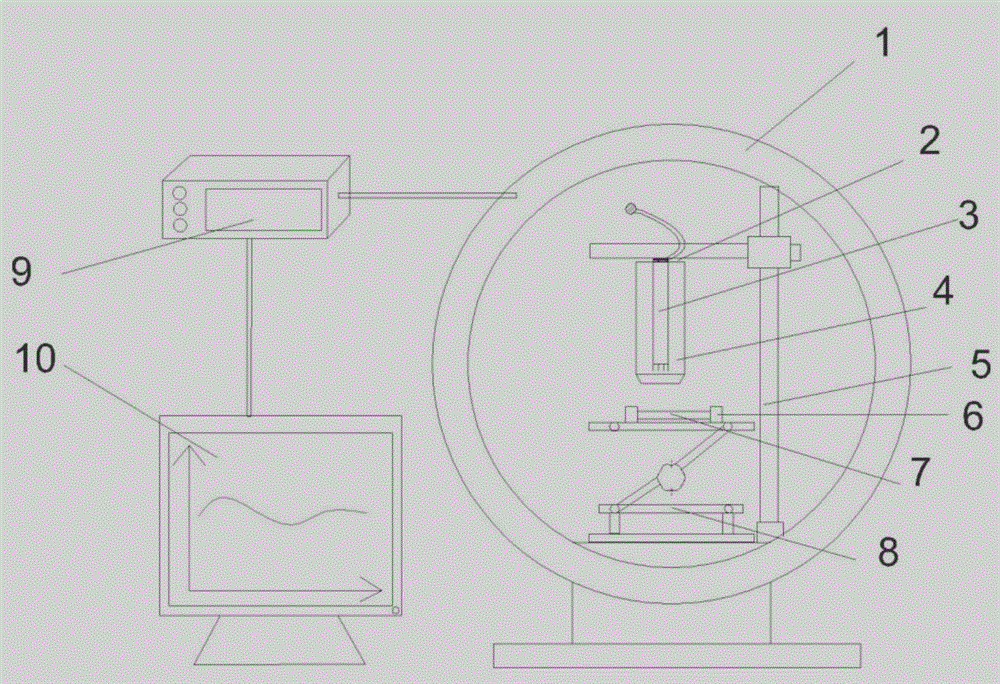

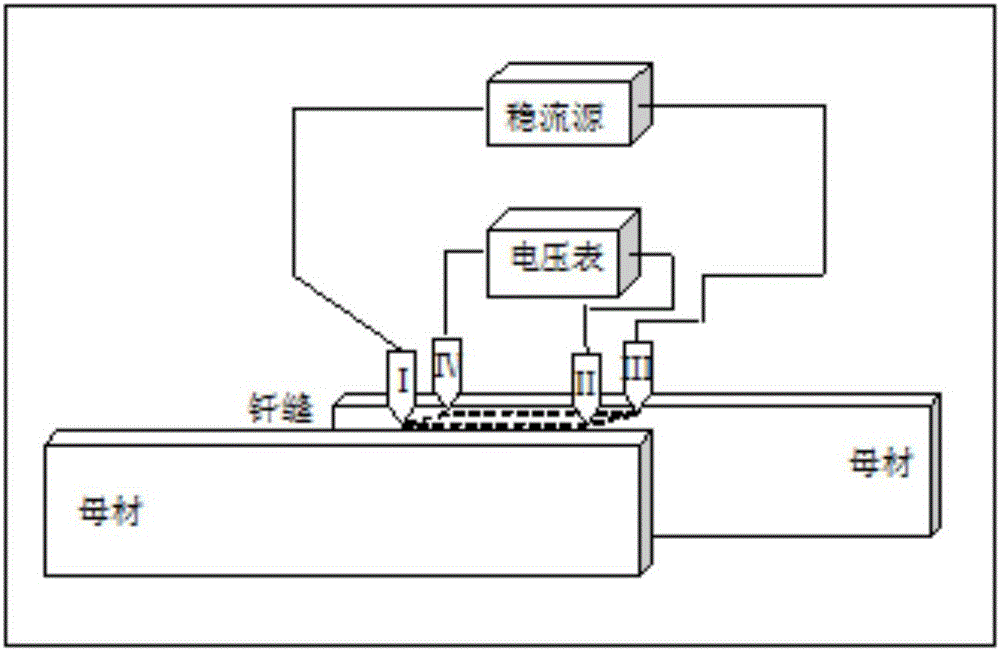

[0055] A non-destructive testing method and device for on-line monitoring of the resistance value of metal brazed joints and indirect evaluation of joint performance, including: brazed joints to be tested, four-probe probes, ceramic wires, clamps, liftable devices with universal joints, Four-probe resistance meter and computer. The brazing sample to be tested includes the base material area of the brazing joint and the brazing seam area of the brazing joint. The brazing seam area of the brazing joint to be tested is in the middle of the lap joint, and the area of the four-probe probe is smaller than that The area of the seam area, the four-probe probe is composed of four metal electrode rods and a ceramic shell, the four metal electrode rods are distributed in parallel, the four-probe probe is fixed on a liftable device with a universal head, and the four-probe probe The signal is connected to the signal acquisition end of the four-probe resistance m

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap