Dyeing waste liquid special treatment device

A special treatment and dyeing waste liquid technology, applied in the direction of filtration treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of unfavorable daily operation and use, high operating cost, complicated process, etc., to increase sewage Treatment efficiency, reduction of operating costs, reduction of process flow effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

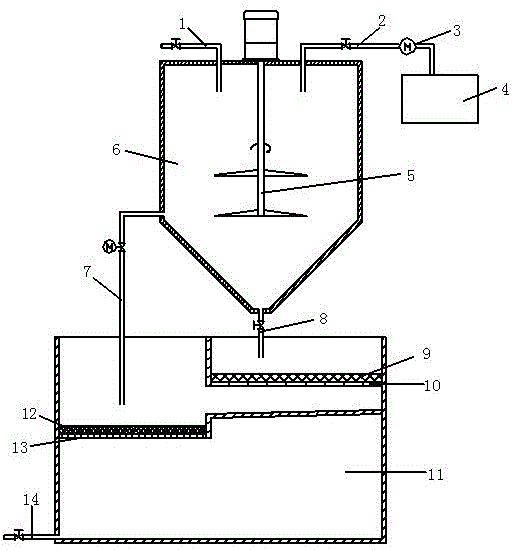

[0016] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0017] Refer to attached figure 1 A special treatment device for dyeing waste liquid shown includes a sedimentation chamber 6 and a filter adsorption chamber 11. The bottom of the adsorption filter chamber is provided with a drain pipe 14. The sedimentation chamber 6 is a PP corrosion-resistant device with a capacity of between 50-200L. Between, the bottom of the precipitation chamber 6 is a conical structure, the precipitation chamber 6 is arranged above the filter adsorption chamber 11, the interior of the precipitation chamber 6 is provided with a stirrer 5, and the top is provided with a waste liquid inlet pipe 1 and the dosing pipe 2, the bottom is provided with a sludge discharge pipe 8, a sewage switch valve is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap