Vibration plate device for supplying of aluminum cases

A vibrating plate and aluminum shell technology, applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of no detection mechanism, complex structure, instability of the rejection device of the reverse aluminum shell, etc., and achieve the accuracy rate. High, the effect of eliminating errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

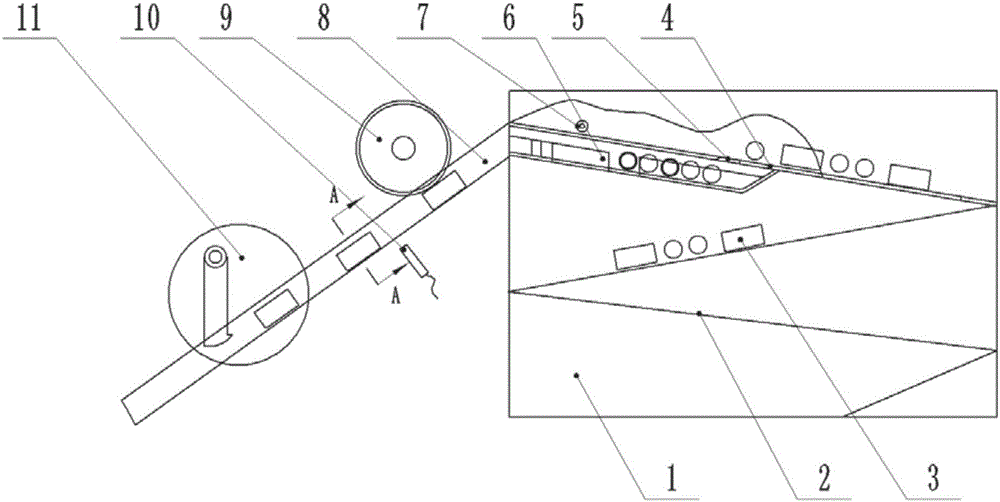

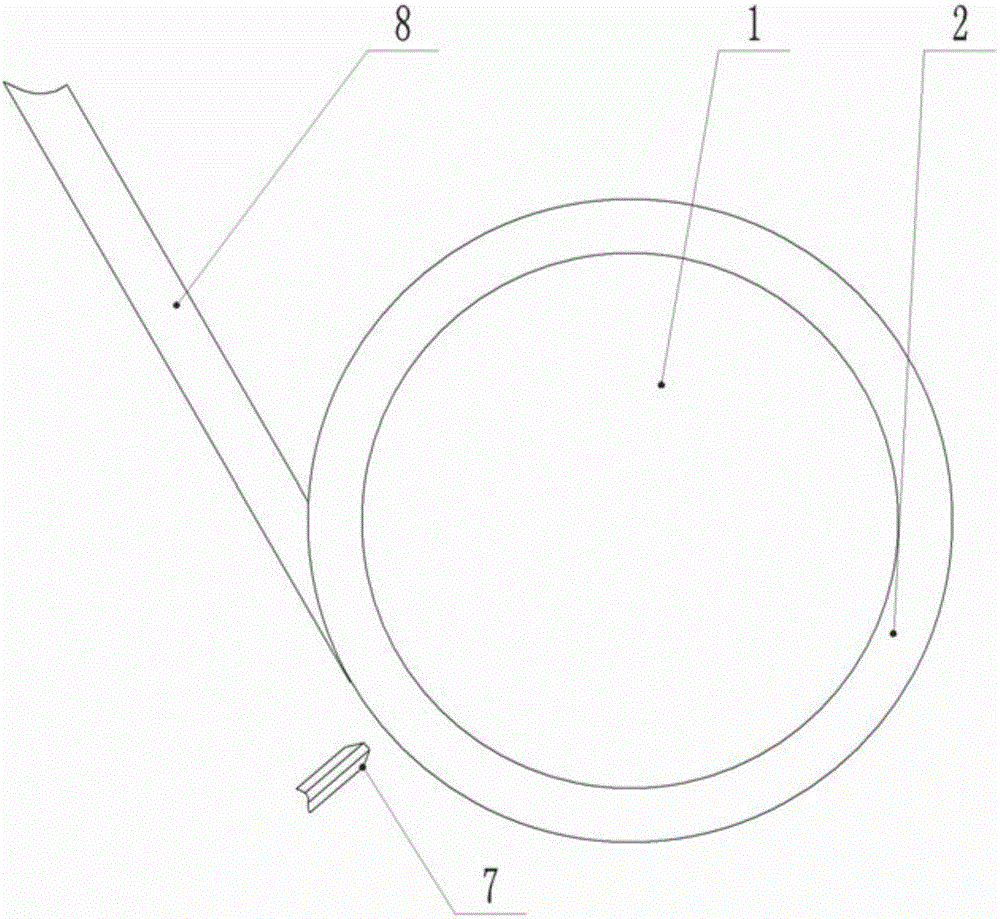

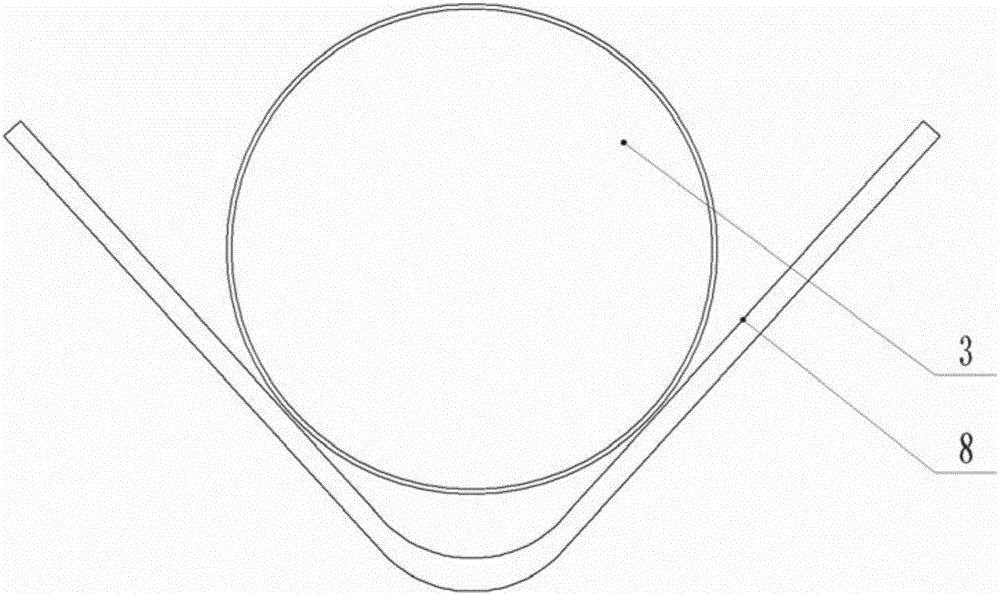

[0039] Such as Figure 1-2 As shown, a vibrating plate device for feeding aluminum shells according to the embodiment of the present invention includes: a rotating track 2 is installed inside the vibrating plate 1, and the uppermost part of the rotating track 2 is an upper track 4; The gap 5 of the upper track, the gap 5 of the upper track is close to the exit to process the bevel 51, which is convenient for the aluminum shell to drop, the width of the gap 5 of the upper track is larger than the diameter of the aluminum shell 3, which is the diameter of the aluminum shell 3 plus the passing gap, and the direction is the normal direction of the upper track 4 , so that the aluminum shell that moves tangentially along the upper track passes through the track gap, and continues to move upward until it reaches the air nozzle, and is blown to the bottom of the vibrating plate by the air nozzle, and then participates in vibration feeding again. And the aluminum shell that moves along th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap