Sewage purifying agent with low solid residual rate

A technology of sewage purifier and residual rate, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of unsatisfactory sewage purification effect, subsequent utilization of pollution, high cost, etc. To achieve the effect of reducing the solid residue rate, reliable effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

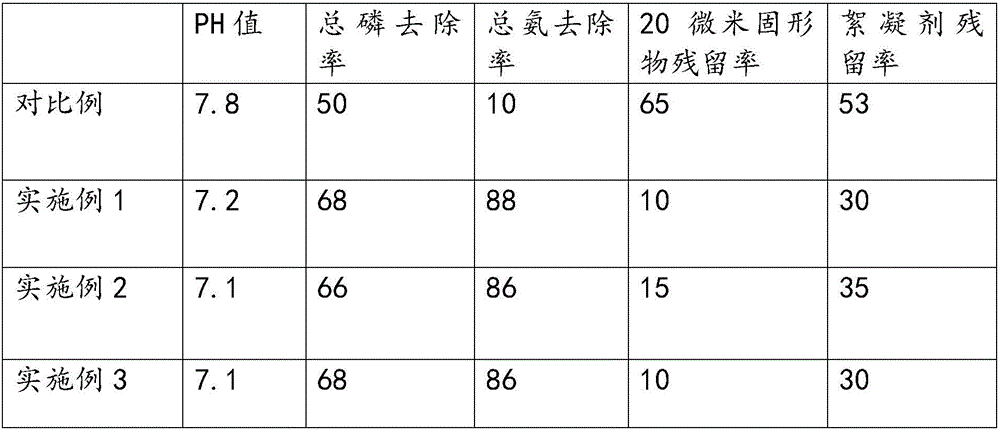

Embodiment 1

[0018] The invention provides a sewage purifying agent with a low solid residual rate, which comprises the following components in parts by weight: diatomite, 35 parts; activated carbon, 50 parts; vermiculite powder, 25 parts; dickite, 30 parts; sericite powder, 12 parts; natural gypsum, 18 parts; zinc stearate, 5 parts; carboxymethyl cellulose, 5 parts.

[0019] The purifying agent is in the form of fine powder.

[0020] The particle size of the purifying agent fine powder is 0.08mm.

[0021] A preparation method with low solid residue rate, comprising the steps of:

[0022] Step S1, mixing and grinding diatomite, activated carbon, vermiculite powder, dickite, sericite powder and natural gypsum into fine powder;

[0023] In step S2, the fine powder in step S1 is uniformly mixed with zinc stearate and carboxymethyl cellulose.

[0024] Further, the particle size of the fine powder is 0.08mm.

[0025] A method for using a sewage purifying agent with a low solid residue rate, wh

Embodiment 2

[0027] A kind of sewage purification agent with low solid residue rate, comprising the following components by weight, diatomite, 50 parts; activated carbon, 55 parts; vermiculite powder, 30 powders; dickite, 35 parts; sericite powder, 20 parts parts; natural gypsum, 25 parts; zinc stearate, 8 parts; carboxymethylcellulose, 7 parts.

[0028] The purifying agent is in the form of fine powder.

[0029] The particle size of the purifying agent fine powder is 0.5mm.

Embodiment 3

[0031] A kind of sewage purification agent with low solid residue rate, comprising the following components by weight, diatomite, 20 parts; activated carbon, 45 parts; vermiculite powder, 20 powders; dickite, 20 parts; sericite powder, 10 parts parts; natural gypsum, 15 parts; zinc stearate, 4 parts; carboxymethylcellulose, 5 parts.

[0032] The purifying agent is in the form of fine powder.

[0033] The particle size of the purifying agent fine powder is 0.02mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap