Modified carboxymethyl cellulose as well as preparation method and application thereof

A carboxymethyl cellulose and modification technology, applied in the field of modified carboxymethyl cellulose and its preparation, can solve the problems of low adsorption effect, no environmental friendliness of the adsorbent, etc., and achieve superior performance and simple preparation steps. , the effect of mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing modified carboxymethyl cellulose, comprising the following steps:

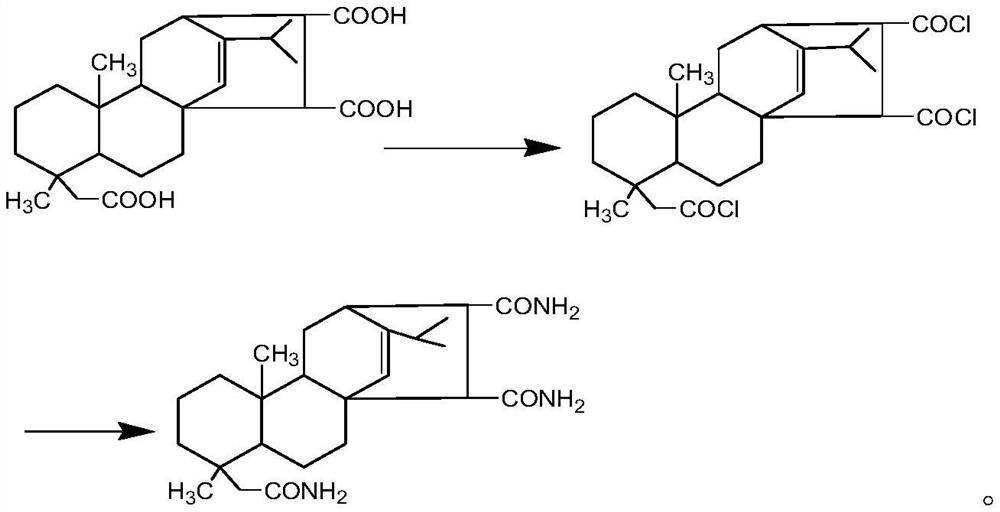

[0032] (1) 43.23 maleisone acid was dissolved in 200ml of dichloromethane, after adding 53.54g of sulfoxide chloride at 0 °C, at 10 °C, the reaction was 4h, and 47.62g of maleis pineyl chloride was obtained after steaming;

[0033] (2) Add 47.62g of maleissoneyl acid chloride to 200mL tetrahydrofuran, inject ammonia gas until alkaline is measured with pH test strip at the mouth of the reaction bottle, and then react at 5 °C for 6h, and 40.27g maleissone amide is obtained after spinning;

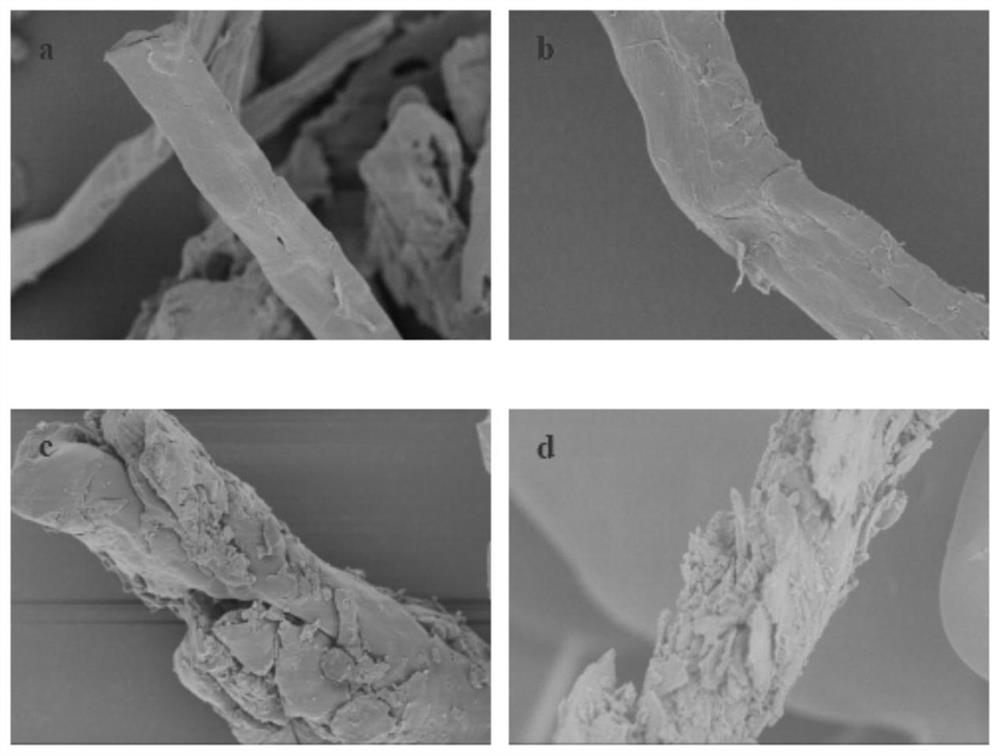

[0034] (3) Dissolve 0.5g carboxymethyl cellulose in 50ml of pure water, add 0.5g maleissone amide, stir well, add 0.5g EDC and 0.5g NHS after sonication for 10min, continue stirring, 25 °C reaction for 24h, after the end of the reaction, centrifuge, wash the resulting sample with pure water and ethanol 5 times, and freeze-dry at -60 °C to obtain a modified carboxymethyl cellulose aerogel.

[0035] Among

Embodiment 2

[0049] A method for preparing modified carboxymethyl cellulose, comprising the following steps:

[0050](1) 43.23 maleisone acid was dissolved in 200ml of dichloromethane, after adding 35.7g of sulfoxide chloride at 10 °C, at 10 °C, the reaction was 6h, and 44.38 g of maleissone ylyl chloride was obtained after steaming;

[0051] (2) 44.38g maleissone yl chloride was added to 200mL tetrahydrofuran, injected with ammonia gas, until alkaline was measured with pH test strip at the mouth of the reaction bottle, and then reacted at 0 °C for 4h, and 37.56g maleissone amide was obtained after steaming;

[0052] (3) Dissolve 0.5g carboxymethyl cellulose in 50ml of pure water, add 1g maleissone amide, stir well, add 0.5g EDC and 0.5g NHS after sonication for 10min, continue stirring, 40 °C reaction for 36h, after the reaction, centrifuge, wash the resulting sample with pure water and ethanol 5 times, and freeze-dried at -60 °C to obtain a modified carboxymethyl cellulose aerogel.

[0053] Amo

Embodiment 3

[0059] A method for preparing modified carboxymethyl cellulose, comprising the following steps:

[0060] (1) Dissolve 43.23 maleisone in 200ml of dichloromethane, add 71.40g of sulfoxide chloride at 20 °C, react at 20 °C for 8h, and after steaming to give 46.08g of maleis pineyl chloride;

[0061](2) 46.08g of maleissone yl chloride was added to 200mL tetrahydrofuran, and ammonia was introduced until alkaline was measured with pH test strip at the mouth of the reaction bottle, and then after the reaction at 25 °C for 8h, 39.26g of maleissone amide was obtained after steaming;

[0062] (3) Dissolve 0.5g carboxymethyl cellulose in 50ml of pure water, add 0.25g maleissone amide, stir well, add 0.5g EDC and 0.5g NHS after sonication for 10min, continue stirring, 30 °C reaction for 30h, after the end of the reaction, centrifuge, wash the resulting sample with pure water and ethanol 5 times, and freeze-dried at -60 °C to obtain a modified carboxymethyl cellulose aerogel.

[0063] Among the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap