Spraying glue for water-based bags, suitcases and handbags and preparation method thereof

A luggage and handbag technology, applied in the field of adhesive glue, can solve the problems of difficult storage, flammability, human body hazards, etc., and achieve the effect of strong practicability and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

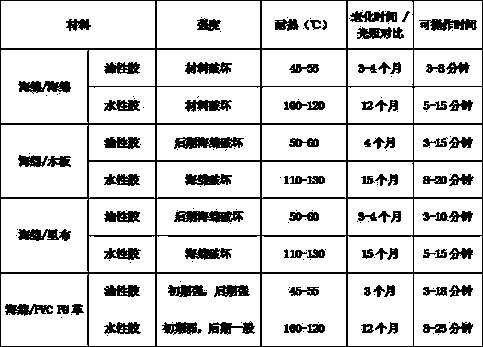

Image

Examples

Embodiment 1

[0015] Embodiment 1: a kind of water-based bag handbag spray glue, is made up of the raw material of following weight: polybutadiene 55kg, cornflour interpolymer 3kg, hydroxymethyl cellulose sodium 28kg, ammonium gum 4kg, defoamer 3kg .

[0016] Polybutadiene is a highly crystalline butadiene dispersion, the solid content of the high crystalline butadiene dispersion is 55%, the pH value is 13, the viscosity is 100Pa·s, the density at room temperature is 1.12%, and the water content is 45wt %.

[0017] The corn flour copolymer is composed of corn starch and water, the quality of corn starch accounts for 10% of the corn flour copolymer, and the water is boiling water at 100 °C. When preparing the corn flour copolymer, the cornstarch is added into boiling water and boiled for 3 minutes, and then it becomes a paste after cooling.

[0018] Yamnia gum is a natural rubber produced in Hainan. The solid content of Yamnia gum is 60.5%, the viscosity is 500S, and the amine content is 0.72

Embodiment 2

[0024] Embodiment 2: a kind of water-based bag handbag spray glue, is made up of the raw material of following weight: polybutadiene 65kg, cornflour copolymer 5kg, sodium hydroxymethyl cellulose 32kg, ammonium gum 8kg, defoamer 5kg .

[0025] Polybutadiene is a highly crystalline butadiene dispersion, the solid content of the high crystalline butadiene dispersion is 55%, the pH value is 13, the viscosity is 100Pa·s, the density at room temperature is 1.12%, and the water content is 45wt %.

[0026] The corn flour copolymer is composed of corn starch and water, the quality of corn starch accounts for 20% of the corn flour copolymer, and the water is boiling water at 98°C. When preparing the corn flour copolymer, the corn starch is added into boiling water and boiled for 5 minutes, and then it becomes a paste after cooling.

[0027] Yamnia gum is a natural rubber produced in Hainan. The solid content of Yamnia gum is 61.5%, the viscosity is 600S, and the amine content is 0.72wt%.

Embodiment 3

[0033] Embodiment 3: a kind of water-based bag handbag spray glue, is made up of the raw material of following weight: polybutadiene 60kg, cornflour copolymer 3kg, sodium hydroxymethyl cellulose 30kg, ammonium gum 5kg, defoamer 5kg .

[0034] Polybutadiene is a highly crystalline butadiene dispersion, the solid content of the high crystalline butadiene dispersion is 55%, the pH value is 13, the viscosity is 100Pa·s, the density at room temperature is 1.12%, and the water content is 45wt %.

[0035] The corn flour copolymer is composed of corn starch and water, the quality of corn starch accounts for 15% of the corn flour copolymer, and the water is boiling water at 99°C. When preparing the corn flour copolymer, the corn starch is added into boiling water and boiled for 5 minutes, and then it becomes a paste after cooling.

[0036] Yamnia gum is a natural rubber produced in Hainan. The solid content of Yamnia gum is 60%, the viscosity is 550S, and the amine content is 0.72wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap