Incrustation cleaning system for boiler

A boiler cleaning and scaling technology, applied in the field of cleaning systems, can solve the problems of metal overheating, shortened boiler life, difficult to achieve evaporation, etc., to achieve the effect of prolonging the service life and preventing the internal corrosion of the water tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

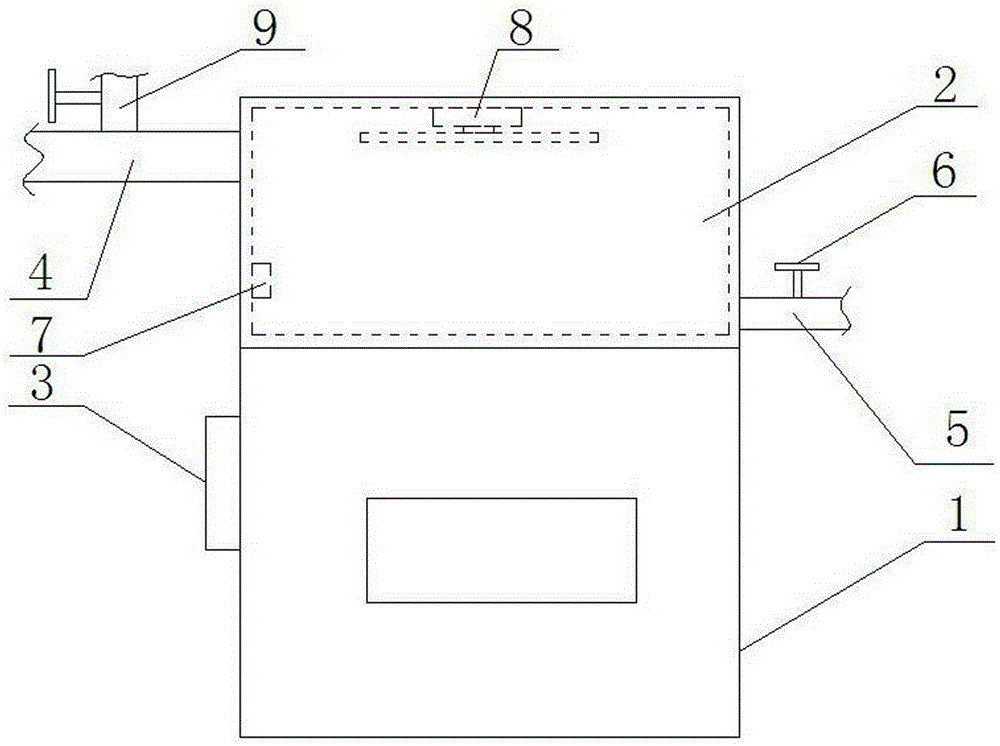

[0019] A boiler scale cleaning system, including a boiler body 1 ; It is characterized in that: the boiler furnace body 1 internal water tank 2 , boiler body 1 control device on the outer surface 3 ; the water tank 2 Water inlet pipe on the upper part of one side 4 , the tank 2 The lower part of the other side is equipped with a water outlet pipe 5 ; the water tank 2 Built-in temperature sensor 7 ; the water tank 2 There is a telescopic stirring device on the inner top surface 8 ; the control device 3 Connect the temperature sensor separately 7 and telescopic stirring device 8 。

[0020] The inlet pipe 4 There is a cleaning agent delivery pipe on the 9 。

[0021] The cleaning agent delivery pipe 9 with valve 6 。

[0022] The outlet pipe 5 with valve 6 。

Embodiment 2

[0024] The working principle of the present invention:

[0025] In the present invention, the electric energy of the boiler equipment can be supplied by the mains, and the control device 3 via temperature sensor 7 Transferred data view tank 2 Internal temperature, through the comparison of temperature rise data, understand the water tank 2 Whether there is a lot of scale inside; when the internal storage data is compared, the water tank 2 The internal water temperature rises slowly, and when it exceeds the normal expected range, other faults can be discharged, and the water tank can be identified 2 There is a lot of scale inside, open the detergent delivery pipe in time, and send it to the water tank 2 Close the outlet pipe at the same time 5 , monitor the water tank through water level gauge and other related equipment 2 internal water level, and utilizes a telescopic agitator 8 , stirring tank 2 A mixture of water and detergent inside to clean

Embodiment 3

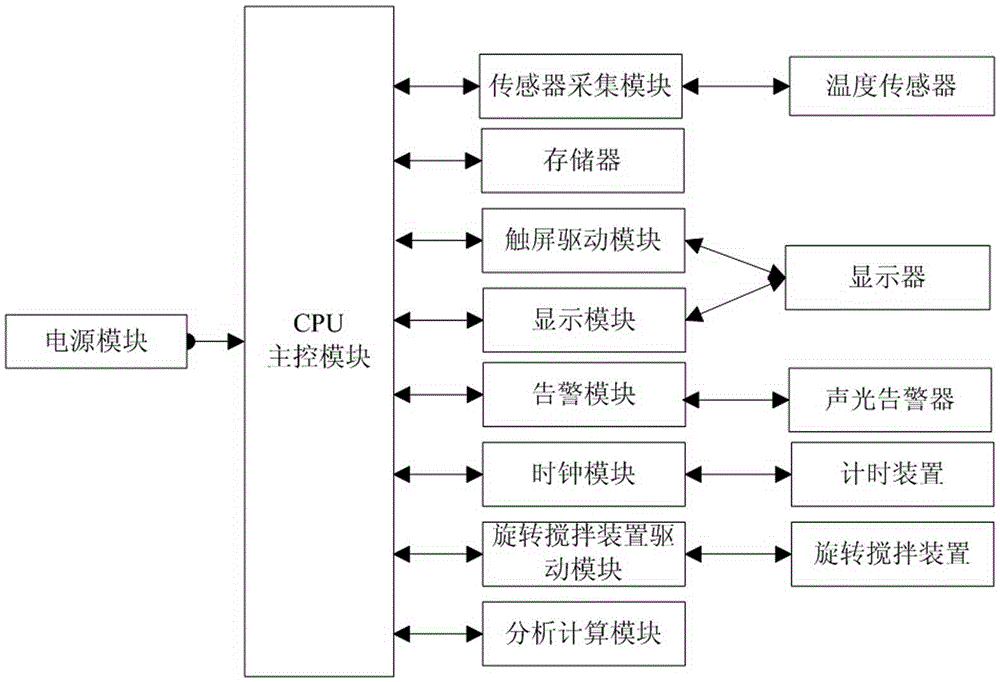

[0027] as shown in the picture 2 Shown, in the present invention, the control device on the boiler 3 The interior includes a power module, CPU Main control module, sensor acquisition module, memory, touch screen driver module, display module, alarm module, clock module, stirring device driver module, analysis and calculation module; the power module is respectively connected to mains and CPU main control module; CPU The main control module is respectively connected to the sensor acquisition module, memory, touch screen driver module, display module, alarm module, clock module, telescopic stirring device 8 A drive module, an analysis and calculation module; the sensor acquisition module is connected to a temperature sensor 7 , the touch screen driver module and the display module are connected to the display; the alarm module is connected to the sound and light alarm; the clock module is connected to the timing device; the stirring device driving module is co

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap