Low-dust environment-friendly alkaline carbon steel welding rod

An environmentally friendly and alkaline technology, applied in the direction of welding media, welding equipment, welding/cutting media/materials, etc., can solve problems such as smoke generation, environmental pollution, and user health hazards, so as to reduce hydrogen partial pressure, reduce pollution, Avoid the effect of cold cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

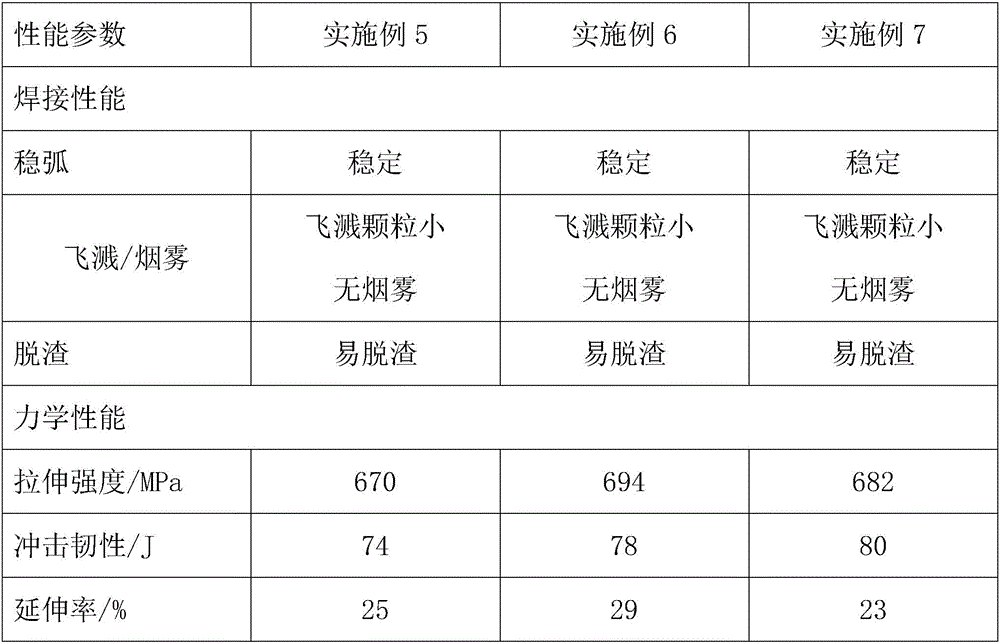

Examples

Embodiment 1

[0034] A low-dust environment-friendly basic carbon steel electrode, including a welding core and a coating coated on the surface of the welding core, the raw materials of the coating include: 35% of marble, 3% of barium carbonate, 7% of magnesite, 5% feldspar, 20% mica iron oxide, 3% wollastonite, 12% rutile, 3% manganese sand, 2% sodium alginate, 1% clay, and the balance is iron powder.

Embodiment 2

[0036] A low-dust environment-friendly basic carbon steel electrode, comprising a welding core and a coating coated on the surface of the welding core, the raw materials of the coating include: 20% of marble, 8% of barium carbonate, 3% of magnesite, 7% feldspar, 12% mica iron oxide, 12% wollastonite, 3% rutile, 8% manganese sand, 1.2% sodium alginate, 1.8% clay, and the balance is iron powder; Fe in mica iron oxide 2 o 3 The content is 90wt%.

Embodiment 3

[0038] A low-dust environment-friendly basic carbon steel electrode, comprising a welding core and a coating coated on the surface of the welding core, the raw materials of the coating include: 15% of marble, 4% of barium carbonate, 6% of magnesite, 6% feldspar, 18% mica iron oxide, 6% wollastonite, 10% rutile, 4% manganese sand, 1.8% sodium alginate, 1.2% clay, and the balance is iron powder; in mica iron oxide, Fe 2 o 3 The content is 92wt%, SiO 2 The content is 4wt%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap