Semi-automatic series water meter verifying and calibration device

A verification device, semi-automatic technology, applied in testing/calibration devices, measuring devices, instruments, etc., can solve problems such as temperature has a great influence on the watch core, limited number of water meters, and watch errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

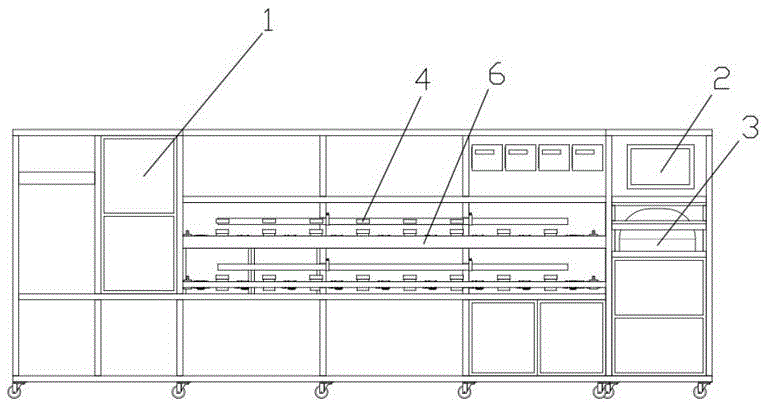

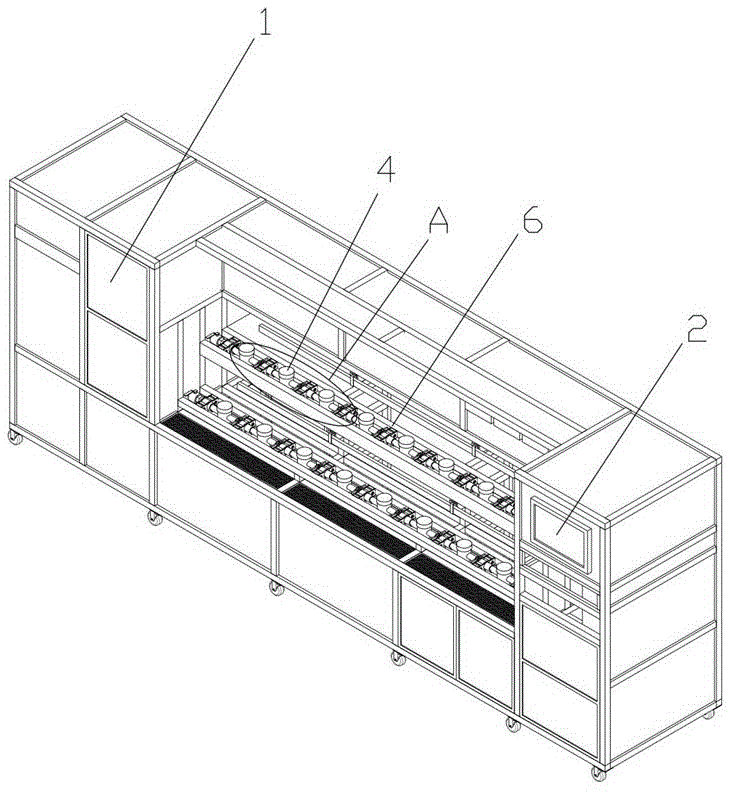

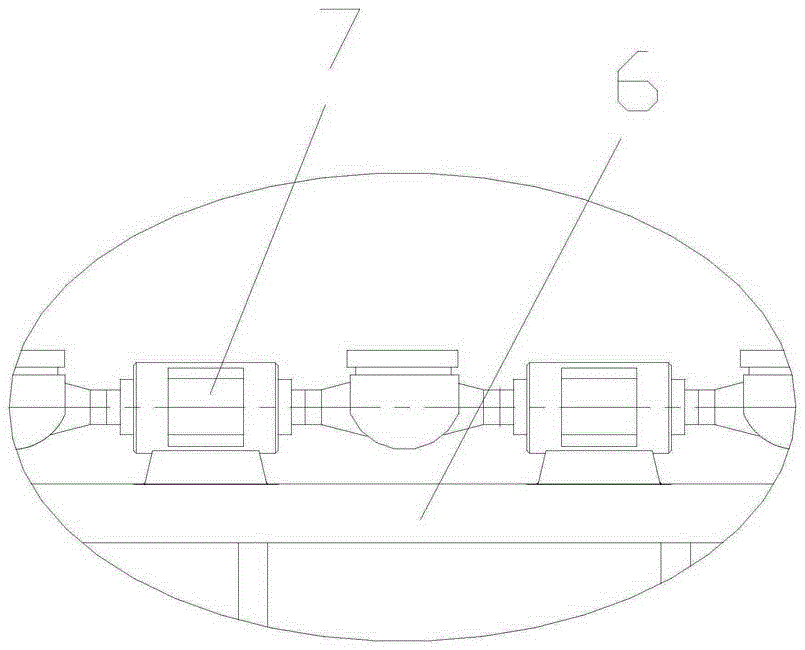

[0029]As shown in the accompanying drawings, a semi-automatic calibrating device for series water meters includes a device body 1, a PLC controller 2, a clamping mechanism, a constant pressure mechanism, a constant temperature mechanism, a flow regulating valve 17, a water tank 3, an image acquisition device 4 and The water pipe 5, the meter clamping mechanism includes a water meter frame 6 and several water meter screw fasteners 7, the water meter frame 6 is installed on the device body 1, and the water meter screw fastener 7 is installed on the water meter frame 6, The inside of the water meter screw fastener 7 is a conduction structure, and the constant pressure mechanism includes a water pump 9, a frequency converter 10, a surge tank 11 and a pressure sensor 12, and the water pump 9, the surge tank 11 and the pressure sensor 12 Connected in series on the water pipe 5, the pressure sensor 12 is also electrically connected to the PLC controller 2, and the PLC controller 2 is als

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap