Electromagnetic engine

A technology of electromagnetic motor and electromagnet, applied in the field of power machinery, can solve the problems of low efficiency of power source, complex structure of electromagnetic motor, polarization of electromagnet coil, etc., and achieve the effect of high-efficiency power source, simple structure and long-lasting power source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

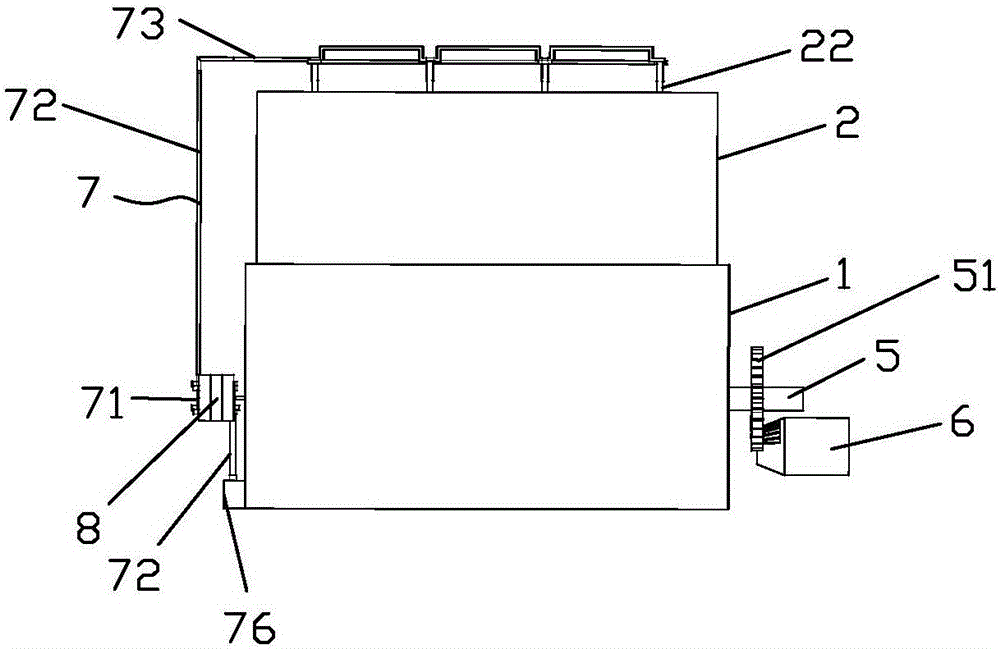

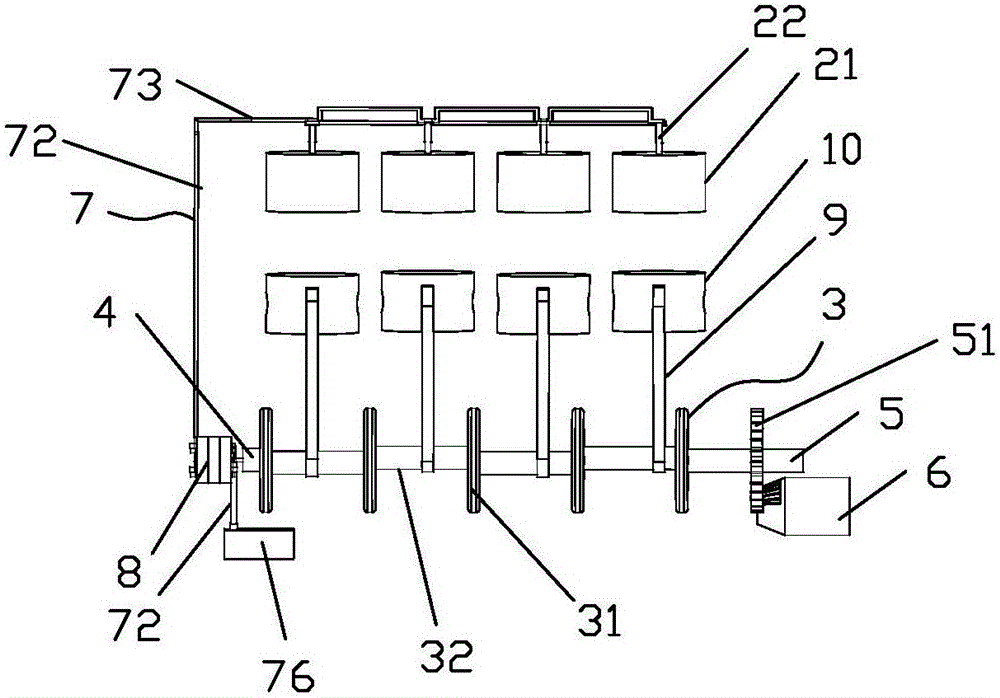

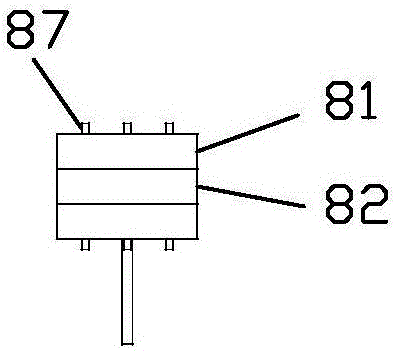

[0031] The present embodiment 1 provides an electromagnetic motor, with reference to figure 1 and figure 2 As shown, it includes a first housing 1 with an opening on the upper end surface and a second housing 2 arranged on the first housing 1 and communicating with the first housing 1. During the specific implementation of the present invention, the second housing 2 The lower end surface of the second housing is provided with a lower opening that communicates with the opening of the first housing; wherein, a crank wheel assembly 3 is horizontally arranged in the first housing 1, and one end of the crank wheel assembly 3 is connected with a cable that passes through the first housing. 1 small crankshaft connecting rod 4 on one side wall, the other end of the crank wheel assembly 3 is connected with the first crankshaft connecting rod 5 protruding from the other side wall symmetrical to the side wall of the first housing 1, protruding out of the first housing The first crankshaft

Embodiment 2

[0044] An electromagnetic motor, the difference between this electromagnetic motor and embodiment 1 is that the electromagnetic motor also includes an electrode converter frame 11, refer to Figure 11 As shown, the electrode converter frame 11 includes a bushing 12 that is sleeved on the electrical connection base block 81 away from the crankshaft small connecting rod 4. A plurality of shaft rods 13, the shaft rods 13 penetrate into the first housing 1, and the electrode converter frame is provided to stabilize the electrode converter.

[0045] refer to Figure 10 As shown, the two electrode columns 22 on the same electromagnet 21 are sleeved with an insulating ring 23, which has a good insulation effect and prevents leakage.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap