Basic mechanical property testing device of drill core sample

A testing device and a core-drilling technology, applied in the field of structural reinforcement testing devices, can solve problems such as complex manufacturing and testing processes, and achieve the effects of true and reliable results, easy testing processes, and simple molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

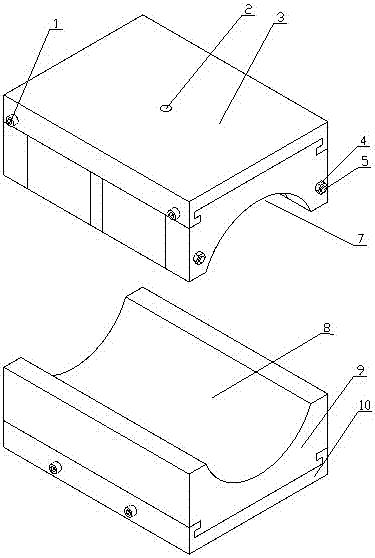

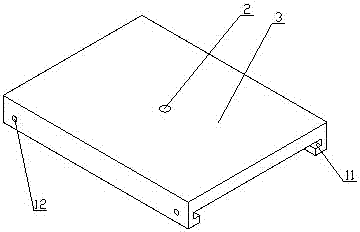

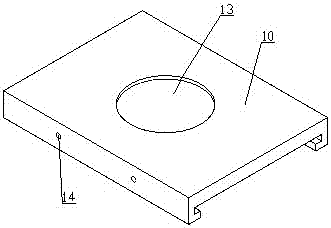

[0022] Such as Figure 1-Figure 6 The basic mechanical performance test device of the core-drilling method sample shown includes an upper connecting seat 3 and a lower connecting seat 10 with a rectangular cross section. The upper middle of the upper connecting seat 3 is provided with a bolt connecting with the lower part of the beam of the testing machine Connect the screw hole 2, the lower part of the lower connecting seat 10 is provided with a circular connecting groove 13 for nested connection with the lower hinge support of the testing machine; the upper connecting seat 3 is provided with an upper pressing seat, and the upper pressing The lower side of the seat is provided with an arc-shaped upper pressurizing groove 7 that is used to fit the outer wall of the core-drilling method sample and penetrates left and right. The upper side of the lower connecting seat 10 is provided with a lower pressurizing seat 9 and the upper side of the lower pressurizing seat 9 An arc-shaped lo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap