Device for detecting uranium concentration in adsorbed tail liquid on line by adopting colorimetric method

A technology of colorimetry and tail liquid, applied in color/spectral characteristic measurement, analysis through chemical reaction of materials, material analysis through observation of the impact on chemical indicators, etc., can solve resource waste and manual analysis errors Large, slow speed and other problems, to achieve the effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] Example 1

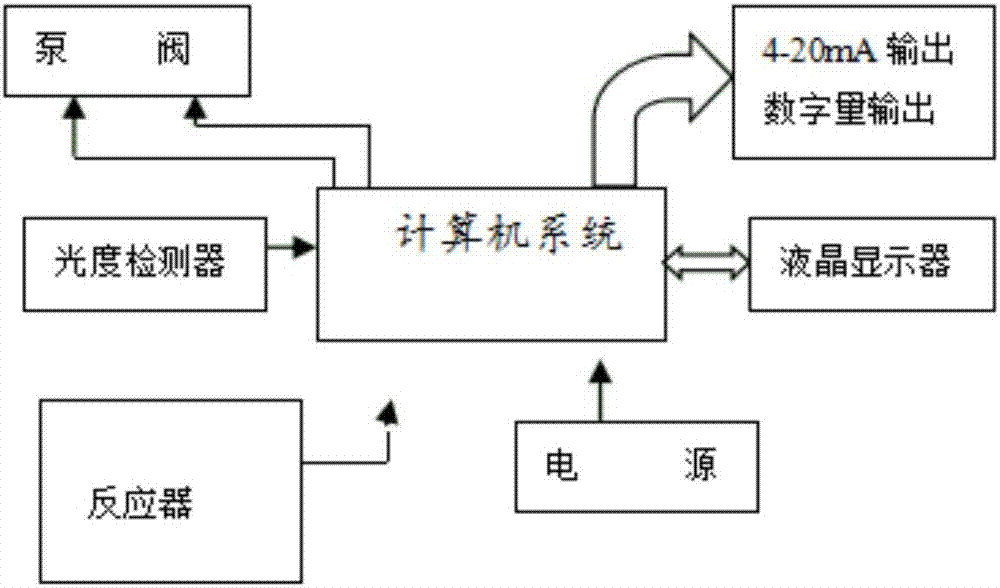

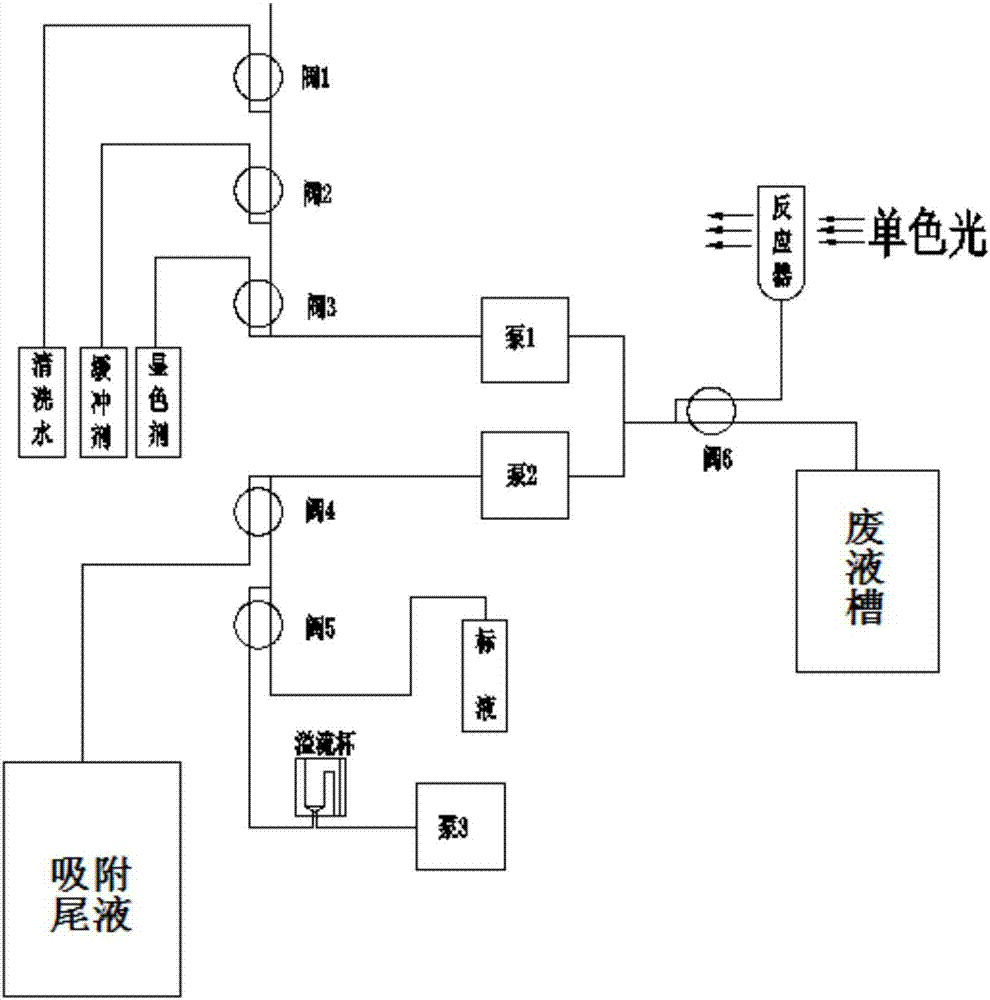

[0025] Such as Figure 1 to Figure 2 As shown, the device of the present invention for online detection of uranium concentration in adsorption tail liquid using colorimetric method includes a chemical flow path system and a control system;

[0026] The chemical flow path system includes a reactor, and a pipeline for injecting the adsorption tail liquid into the reactor, a pipeline for injecting a buffer, a pipeline for injecting a color developer, and a pipeline for injecting cleaning water into the reactor. All are equipped with solenoid valves, and the pipelines are all connected with a peristaltic pump; the chemical flow path also includes a photometric detector for measuring the absorbance of the solution in the reactor.

[0027] The control system includes a computer system, which is connected to a power supply and a liquid crystal display; the computer system is connected to control the peristaltic pump, solenoid valve and photometric detector of the chemical f

Example Embodiment

[0029] Example 2

[0030] In the ion exchange process of a domestic hydrometallurgical plant, such as Figure 1 to Figure 2 As shown, the device for online detection of the concentration of uranium in the adsorption tail liquid using the colorimetric method of the present invention includes a chemical flow path system and a control system;

[0031] The chemical flow path system includes a reactor, and a pipeline for injecting the adsorption tail liquid into the reactor, a pipeline for injecting a buffer, a pipeline for injecting a color developing agent, and a pipeline for injecting cleaning water, in each pipeline All are equipped with solenoid valves, and the pipelines are all connected with a peristaltic pump; the chemical flow path also includes a photometric detector for measuring the absorbance of the solution in the reactor. An overflow cup is set on the pipeline for injecting the adsorption tail liquid into the reactor. After the adsorption tail liquid enters the overflow cup

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap