Combined super long molded wire cutting

A combined, wire-cutting technology, which is applied in the field of ultra-long equipment processing, can solve problems such as inability to process ultra-long equipment by wire-cutting, and achieve high shape and position accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In the following, the present invention will be further described in detail through specific implementation examples in conjunction with the accompanying drawings.

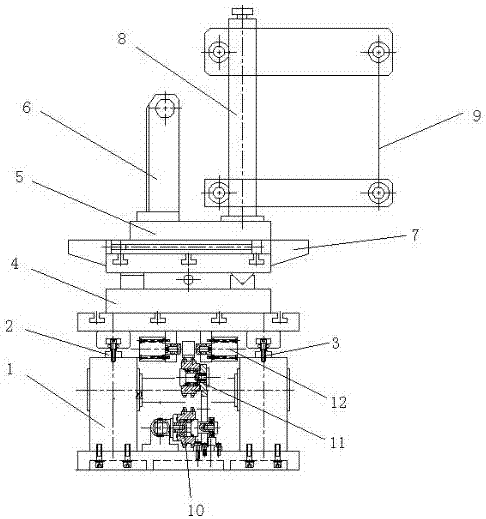

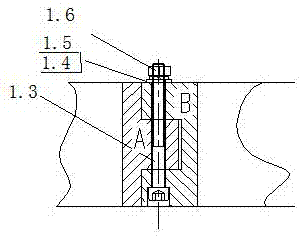

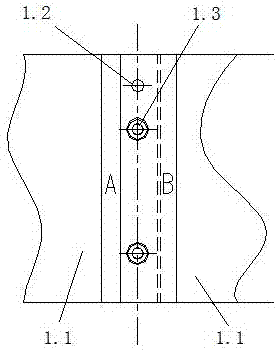

[0019] Such as figure 1 , 2 As shown in 3, a combined ultra-long wire cutting includes: combined reference guide 1, power sliding table 4, wire cutting 5. The combined reference guide 1 is provided with a power sliding table 4, and the power sliding table 4 is The wire cutter 5 is fixed, and the wire cutter 5 has a device for moving up and down along the pole 6 set on the power sliding table 4. The molybdenum wire 9 on the bow body 8 of the wire cutter 5 has a platform that moves stably along the X-axis or Y-axis direction; The roller device 12 of the sliding table 4 is connected with the driving device 10 on the base through the transmission device 11; the combined reference guide rail 1 is composed of a plurality of guide rail bases 1.1 quickly connected to form an ultra-long guide rail base set on a guide rail

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap