Steel wire cutting machine

A cutting and steel wire technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of poor steel wire precision and different lengths, achieve the effect of uniform length and prevent axial runout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail below, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

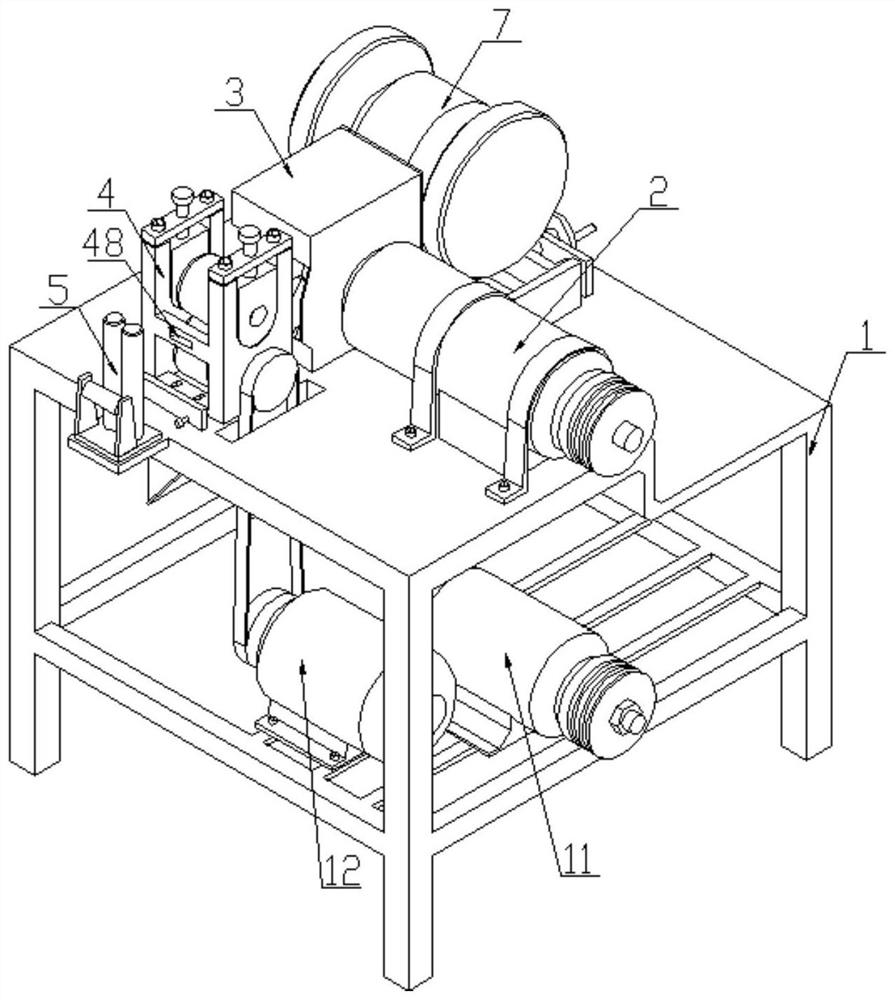

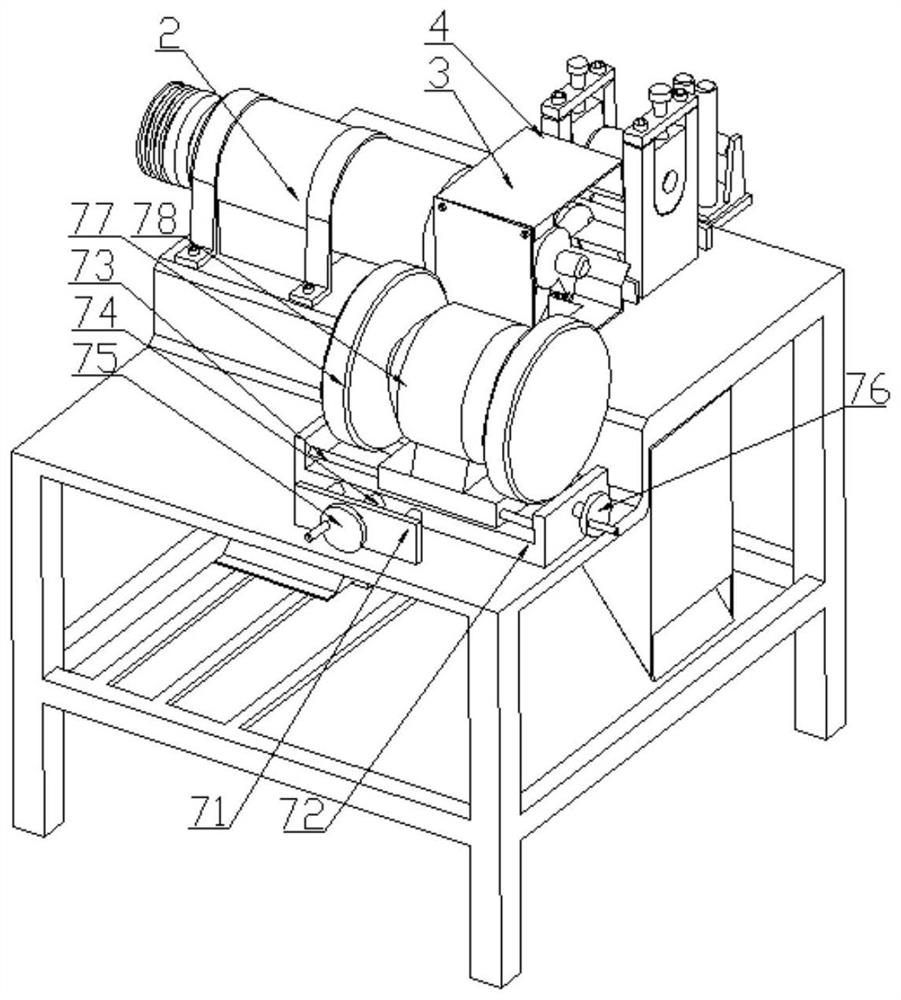

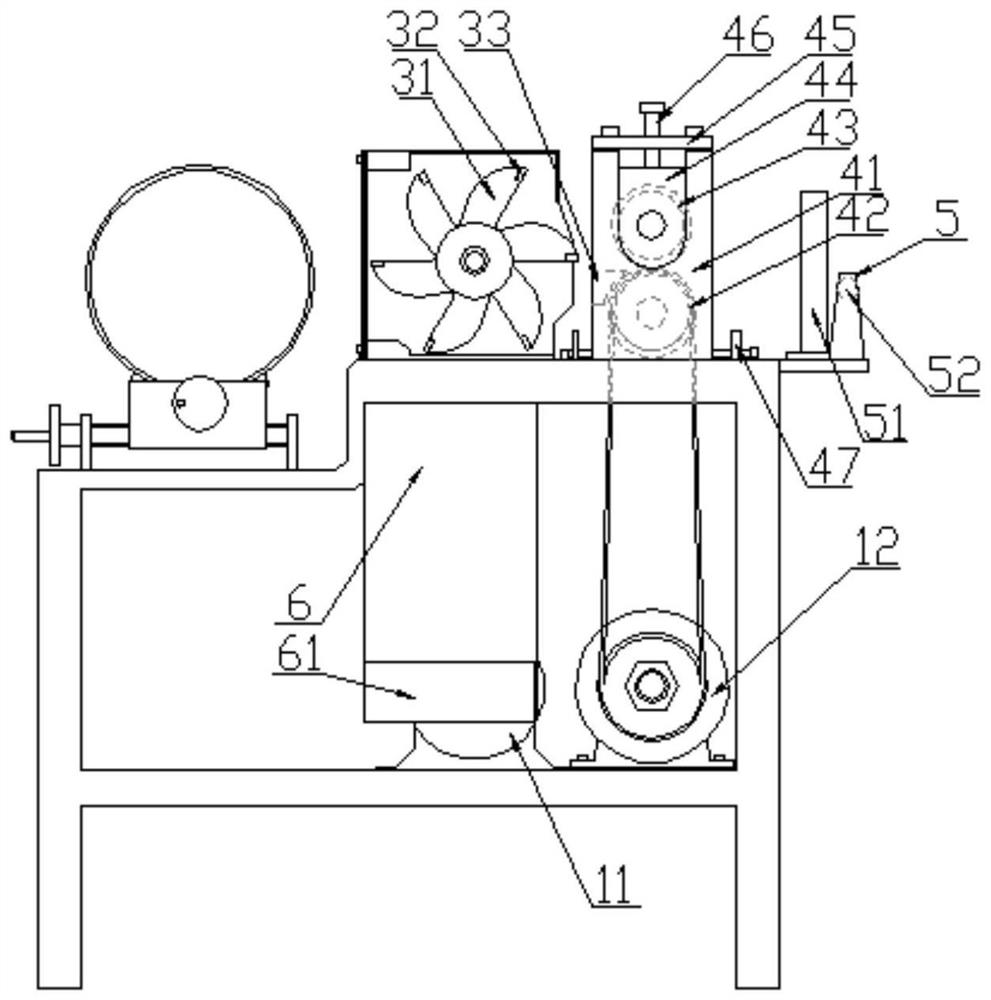

[0018] As shown in the accompanying drawings: a wire guillotine cutting machine, which includes a chassis 1, the chassis 1 is provided with a guillotine cutting drive motor 11, the end of the guillotine cutting drive motor 11 is driven by a belt and a spindle drive box 2 is connected and driven, and the end of the main shaft drive box 2 is connected to the guillotine cutting module 3, and the guillotine cutter seat 31 with an integrated structure is arranged inside the guillotine cutting module 3, and the guillotine cutter seat 31 is equipped with The cloth is provided with several guillotine cutting blades 32 with a radial structure, and the front side of the side cutting blades 32 is provided with a wire feeding assembly 4, and the described wire feeding assembly 4 i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap