Synchronous denitrification reactor

A denitrification and reactor technology, applied in chemical instruments and methods, anaerobic digestion treatment, biological water/sewage treatment, etc., can solve the problems of high project investment and equipment investment, and achieve low equipment investment and simple operation control , the effect of reducing the floor area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

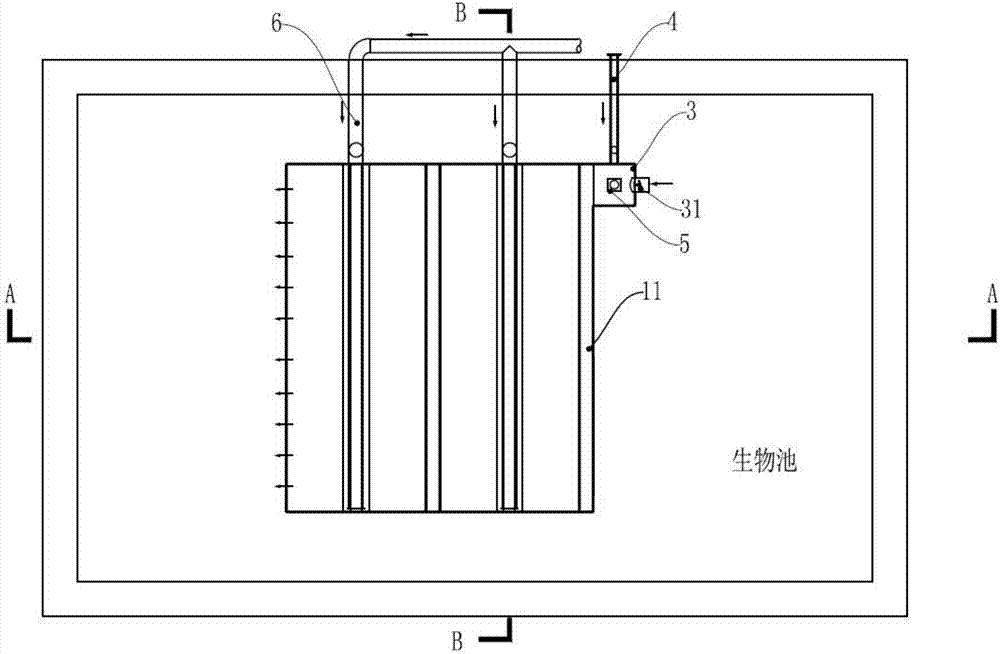

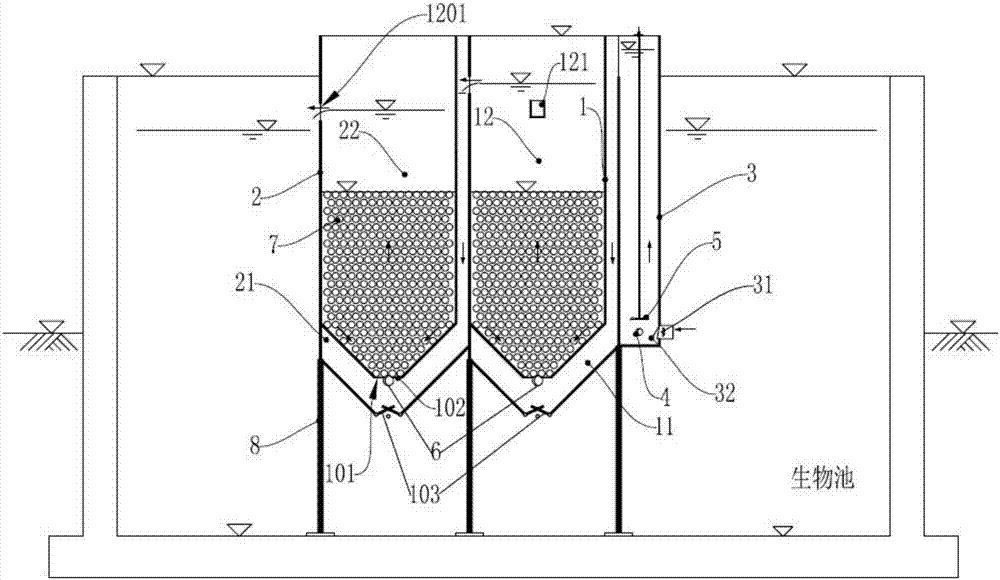

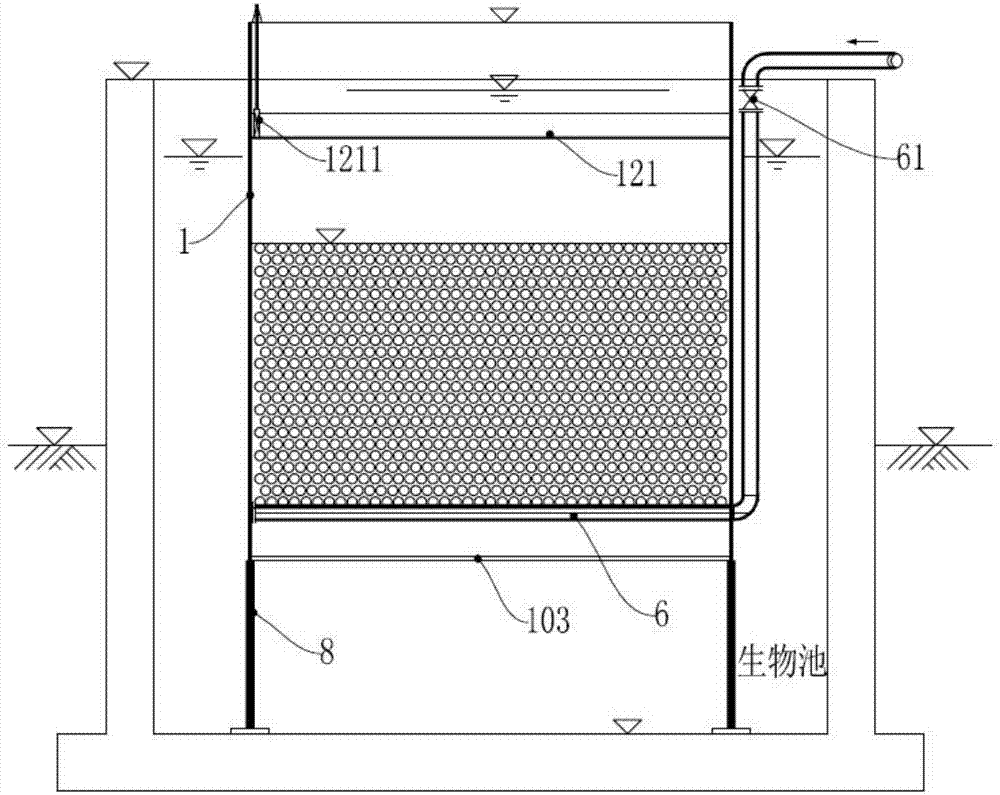

[0039] A synchronous denitrification reactor, comprising a first-stage reaction box 1, a second-stage reaction box 2, an inlet water mixing box 3, a carbon source feeding pipe 4, a mixing agitator 5, a backwashing water pipe 6, and a spherical packing 7;

[0040] The first-order reaction box 1 and the second-order reaction box 2 are connected in series;

[0041] The first-stage reaction tank 1 includes a first water distribution oxygen release chamber 11 and a first denitrification chamber 12;

[0042] The second-stage reaction tank 2 includes a second water distribution oxygen release chamber 21 and a second denitrification chamber 22;

[0043] The bottoms of the first denitrification chamber 12 and the second denitrification chamber 22 are conical, and the bottoms of the first denitrification chambe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap