Vertical support assembly of layered goods shelf for automobile stamping parts

A technology for automotive stamping parts and vertical brackets, applied in tool storage devices, manufacturing tools, etc., can solve problems such as difficulty in ensuring smooth operation of manipulators, difficulty in moving support parts, and increased defect rate of workpieces, so as to ensure movement and stacking, and facilitate replacement , Accurate and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The shape, structure, connection relationship and working principle of each component involved in the specific embodiment of the present invention will be further described in detail below by referring to the accompanying drawings and through the description of the embodiments.

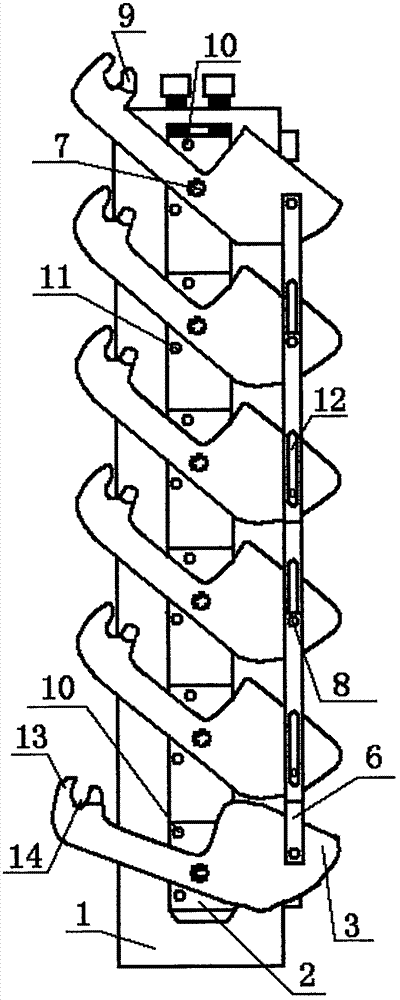

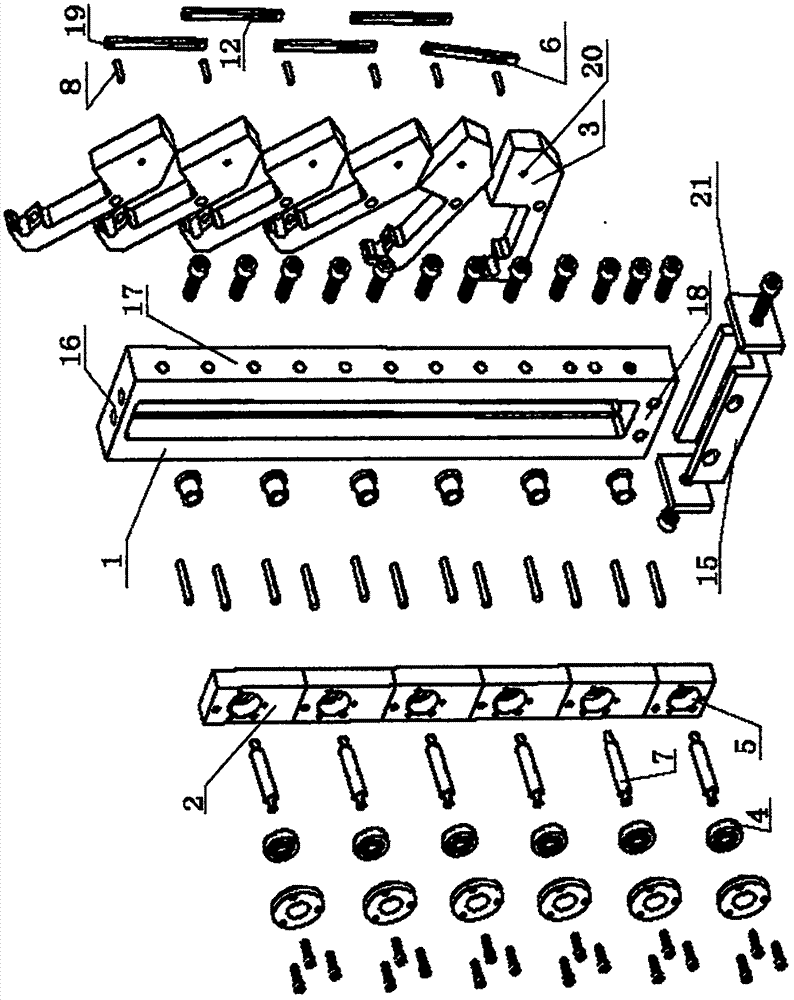

[0020] figure 1 It is a structural schematic diagram of a vertical support assembly of a layered shelf for automobile stamping parts according to the present invention; figure 2 It is an exploded view of a vertical support assembly of a layered shelf for automobile stamping parts of the present invention; as shown in the figure, a vertical support assembly of a layered shelf for automobile stamping parts of the present invention, the vertical support assembly includes a support body 1 and is connected to it The bearing fixing plate 2, the bracket body 1 has a top wall 16, a base 18 and side walls 17 connecting the two ends of the top wall 16 and the base 18 to clamp the bearing fixing plate 2 the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap