LED device

A technology of LED devices and LED chips, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems that LED devices cannot improve the consistency of light and color in barrier performance, so as to ensure the consistency of light and color, improve barrier performance, and improve matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

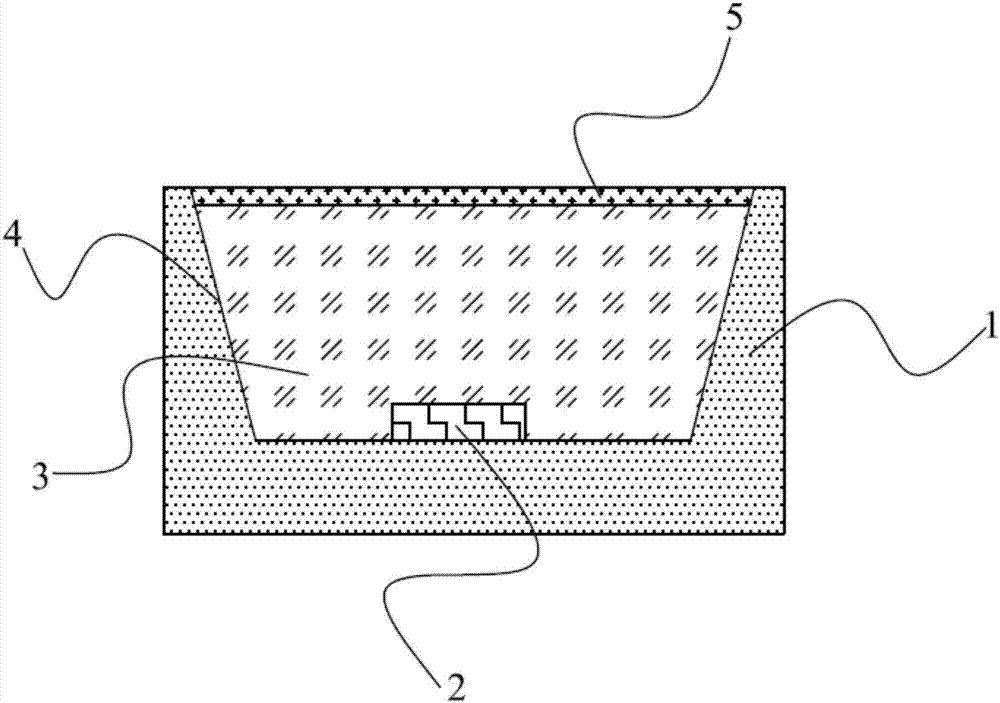

[0058] like figure 1 As shown, this embodiment provides an LED device, including a bracket 1, the bracket 1 is provided with an inverted trapezoidal groove 4, the surface of the groove 4 is provided with a silver-plated layer, the bottom of the groove 4 is provided with a bipolar chip, and the groove 4 is provided with a bipolar chip. 4. The inside is filled with an encapsulating adhesive layer 3 covering the bipolar chip, and the encapsulating adhesive layer 3 is organic silica gel mixed with yellow fluorescent powder. The surface of the encapsulation adhesive layer 3 is provided with an isolation layer 5, the isolation layer 5 is a polymer, and its molecular formula is (Ph 3 SiO 1 / 2 ) a (CH 3 SiO 3 / 2 ) b ((CH 3 ) 2 SiO 2 / 2 ) c (SiO 2 ) d , where a:b:c:d=10:25:35:35. The isolation layer 5 is coated on the upper surface of the encapsulation adhesive layer 3 by spraying. The isolation layer 5 is used to prevent the encapsulation adhesive layer 3 and the light ref

Embodiment 2

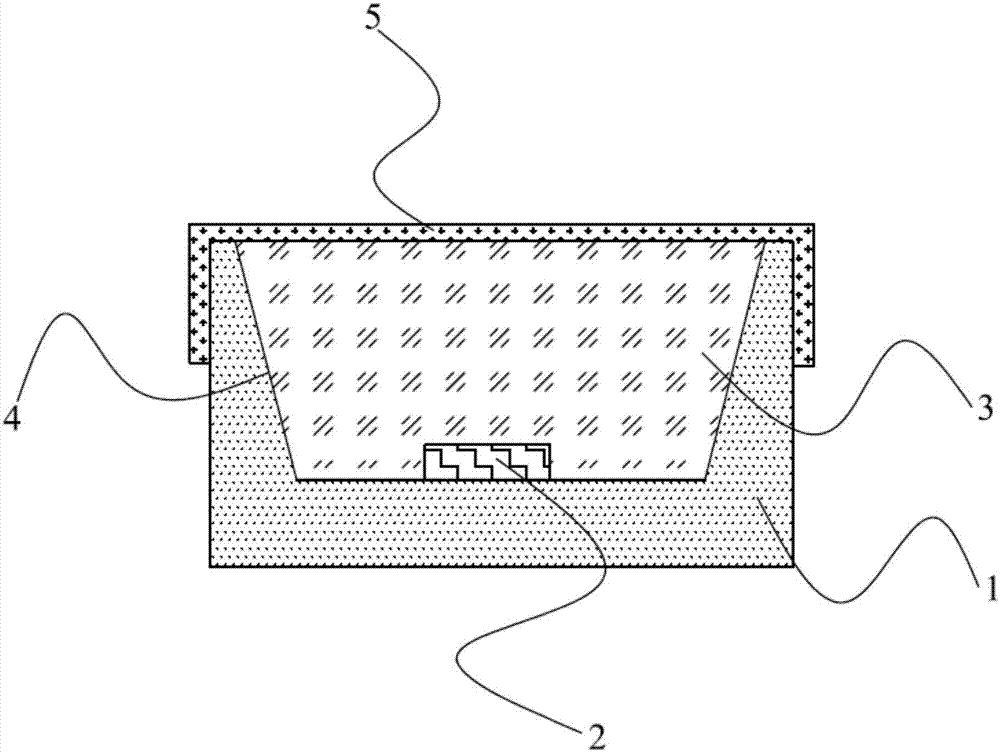

[0060] like figure 2 As shown, the difference between this embodiment and Embodiment 1 is that: the surface of the packaging adhesive layer 3 is provided with an isolation layer 5, and the isolation layer 5 extends to the upper surface and the outside of the bracket 1, so that there is no gap between the packaging adhesive layer 3 and the bracket 1. The thickness of the packaging adhesive layer 3 is 400000nm, the thickness of the isolation layer 5 is 1000nm, and the thickness ratio of the isolation layer 5 to the packaging adhesive layer 3 is 0.25%.

Embodiment 3

[0062] The difference between this embodiment and embodiment 1 lies in that the thickness of the packaging adhesive layer 3 is 600000 nm, the thickness of the isolation layer 5 is 180000 nm, and the thickness ratio of the isolation layer 5 to the packaging adhesive layer 3 is 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap