Synchronous permanent magnet motor machining device for centrifugal blowers

A permanent magnet motor and processing device technology, applied in auxiliary devices, metal processing equipment, manufacturing tools, etc., can solve the problems of cumbersome clamping and replacement of synchronous permanent magnet motor tools, no anti-collision function, and low degree of automation , to avoid the phenomenon of collision, improve the degree of automation and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0018] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

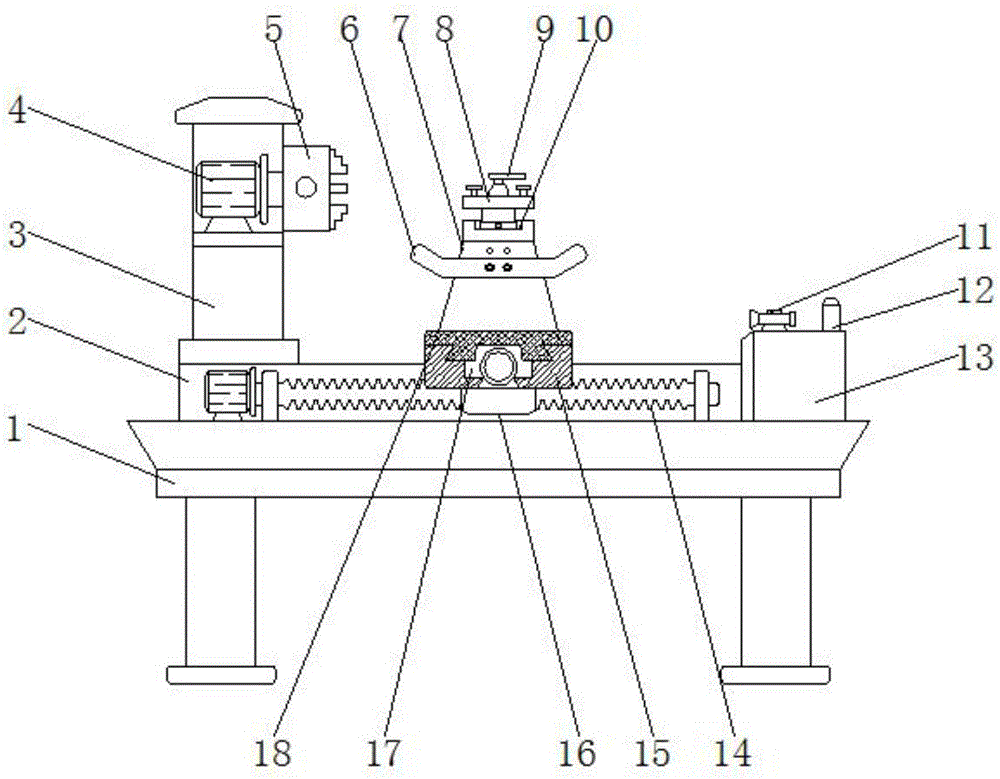

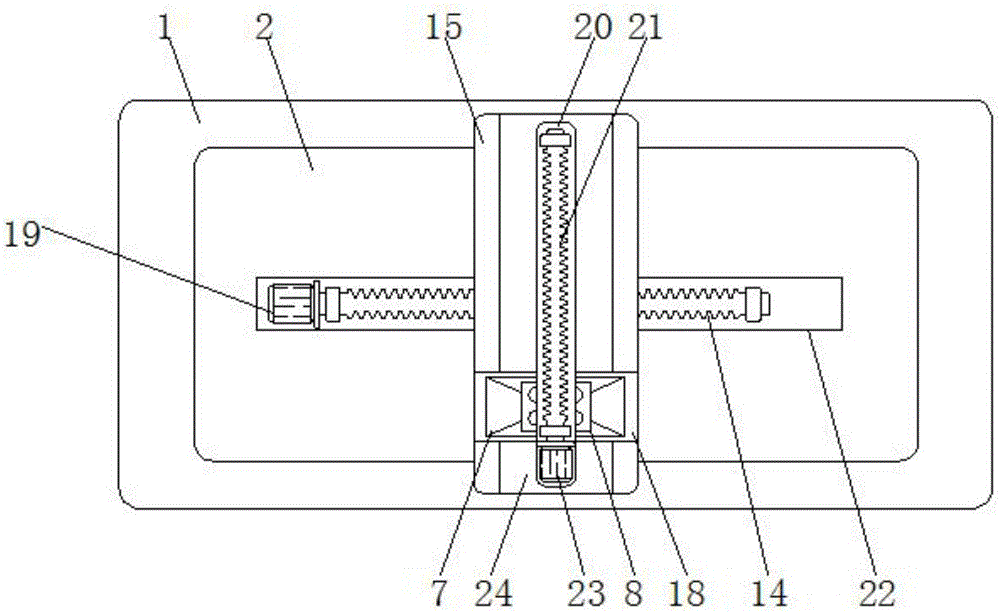

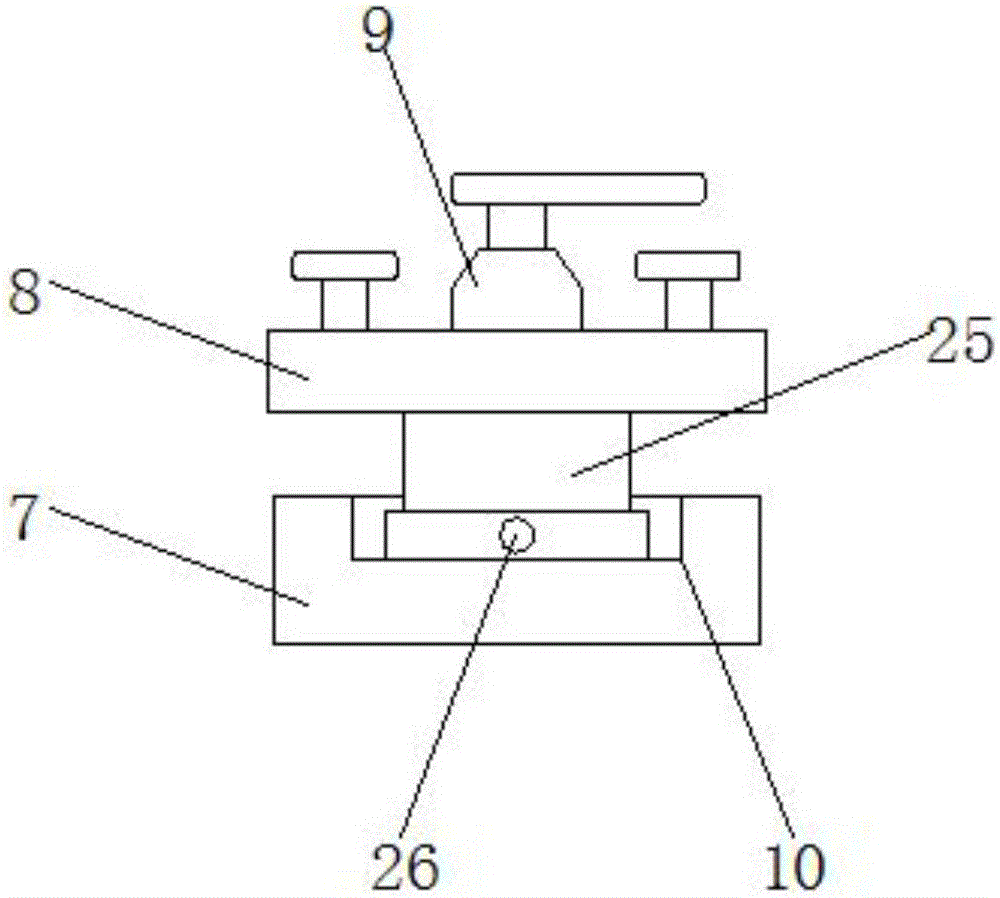

[0019] Such as Figure 1 to Figure 4 As shown, a centrifugal blower synchronous permanent magnet motor processing device includes a device frame 1, a processing base 2, a column 3, a transverse screw 14 and a longitudinal placement cavity 20, and a processing base 2 is fixed at the center of the top of the device frame 1 , A column 3 is installed on the top side of the processing base 2, and a rotating motor 4 is installed inside the column 3 through a support plate. The model of the rotating motor 4 can be Y90L-2. The outer wall of the column 3 at the position of the rotating motor 4 is hinged with three The chuck 5 and the three chuck 5 are connected to the output end of the rotating motor 4 through a coupling. The center of the top of the proces

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap