Multilayer parking equipment with lifting and translating mechanisms

A technology of parking equipment and traverse mechanism, which is applied to the buildings, building types, buildings and other directions where cars are parked. The effect of simplification, promotion and large parking area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0032] The present invention will be further described below in conjunction with the drawings.

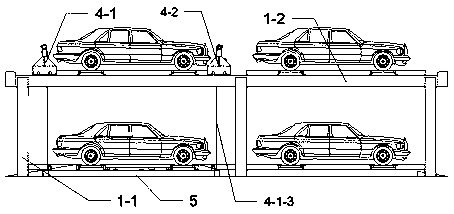

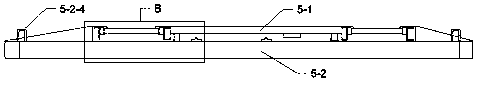

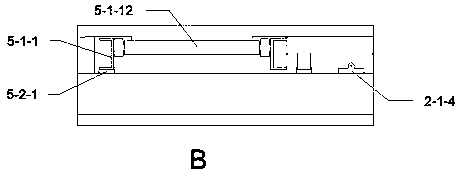

[0033] Such as Figure 1 to Figure 11 The steel frame structure of a multi-storey parking equipment with lifting and traversing mechanisms is shown with parking spaces 2 and car moving channels 3; the steel frame structure includes columns 1-1, beams 1-2, and transverse rafters 1- 3. One end of the column 1-1 is fixed to the ground, and the other end is fixedly connected to the cross rafter 1-3. The cross beam 1-2 includes hoist bearing beam A1-2-1, hoist bearing beam B1-2-2, and parking space bearing beam A1-2-3, parking space bearing beam B1-2-4, hoist bearing beam A1-2-1, and hoist bearing beam B1-2-2 are respectively longitudinally fixed to the columns 1-1 on both sides of the moving passage 3 On the upper cross rafter 1-3; the parking space bearing beam A1-2-4 is provided with a conveying roller table B7, the parking space bearing beam B1-2-4 is provided with a power transmission r

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap