Small-tap all-in-one machine for adding gold threads

An all-in-one, gold wire technology, used in electrical components, packaging/impregnation, inductor/transformer/magnet manufacturing, etc., can solve problems such as inability to use, and achieve the effect of improving stability, increasing movable distance, and avoiding collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

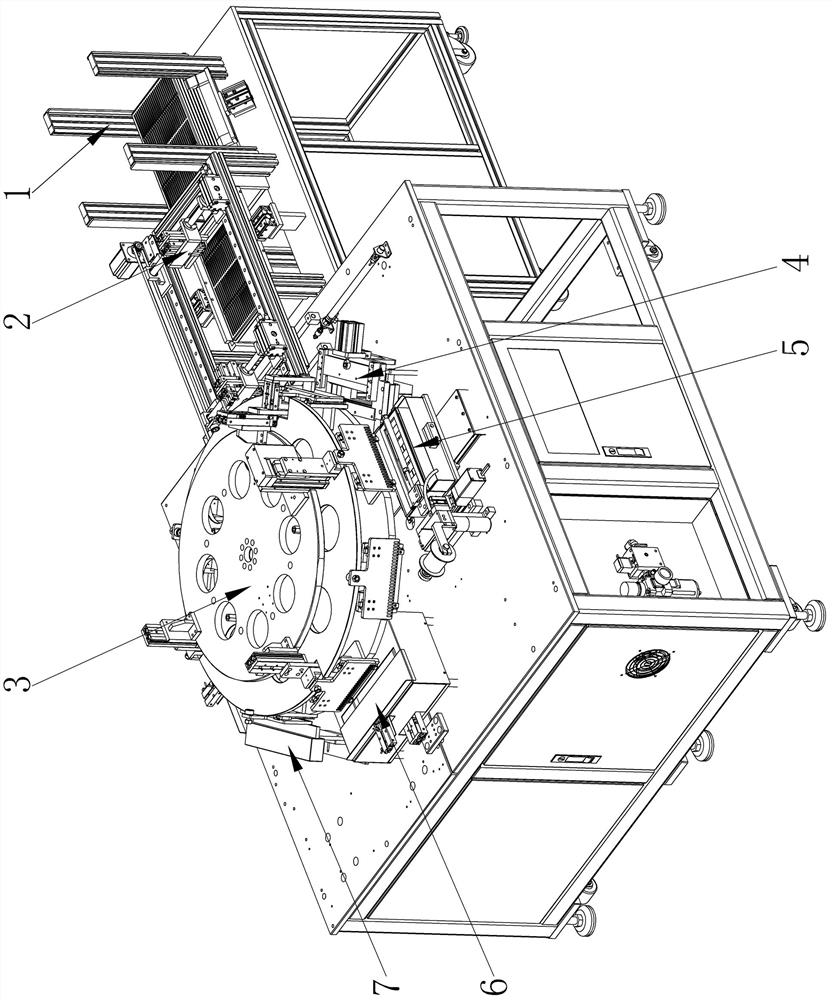

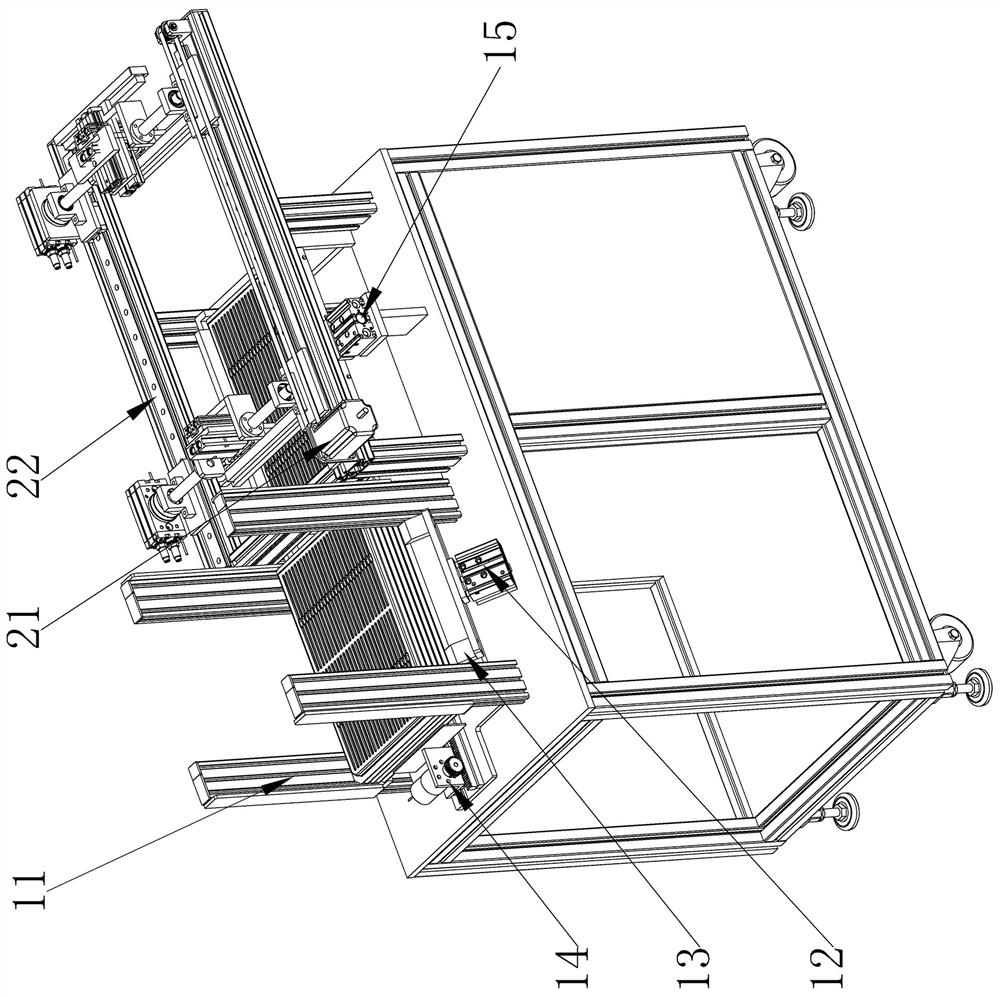

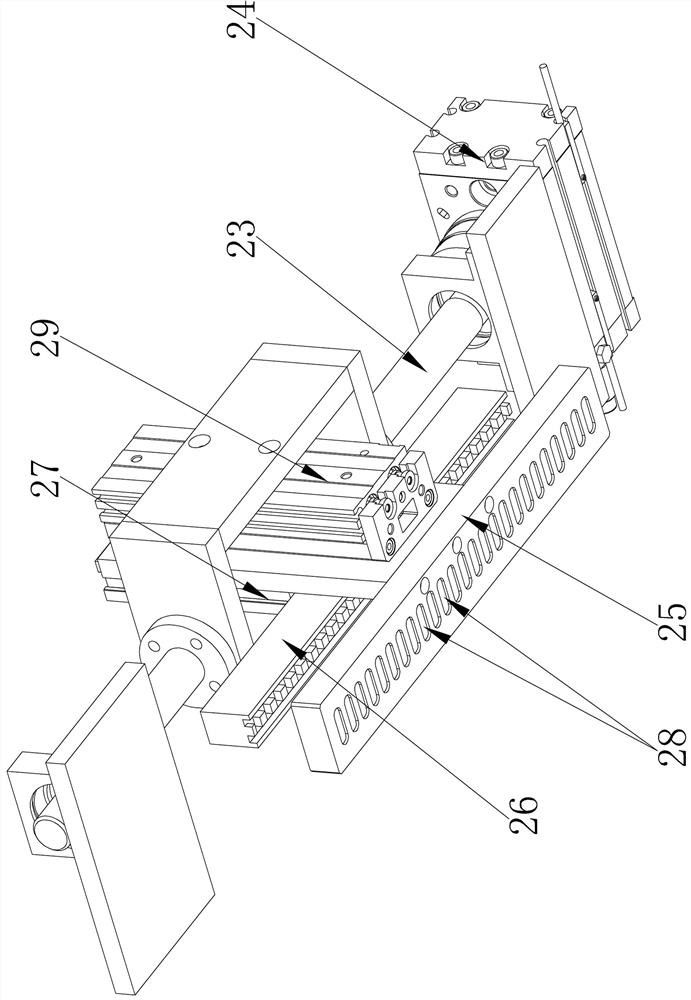

[0032] Such as figure 1 , Figure 7 with Picture 8 As shown, in this embodiment, the present invention includes a disc feeding mechanism 1, a magnetic suction and taking mechanism 2, and a turntable clamping mechanism 3 that are sequentially connected, and a wire clamping mechanism is sequentially arranged along the circumferential direction of the turntable clamping mechanism 3. The thread cutting mechanism 4, the tin immersion mechanism 5 and two sets of dipping and curing mechanisms. The thread clamping and cutting mechanism 4, the tin immersion mechanism 5 and the two sets of dipping and curing mechanisms all cooperate with the turntable clamping mechanism 3. The dipping curing mechanism includes a dipping assembly 6 and a curing lamp 7 arranged in sequence. The dipping assembly 6 includes a dipping tank 61, a light-blocking housing 62, a light-blocking door 63, and a first cylinder 64. The slot 61 is provided in the light blocking housing 62, and a through hole 65 is provide

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap