Floor drain

A floor drain and shell technology, applied in waterway systems, climate change adaptation, drainage structures, etc., can solve problems such as affecting the normal drainage of floor drains, being easily blocked by impurities such as hair, and being difficult to remove, and achieving convenient replacement, easy separation, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

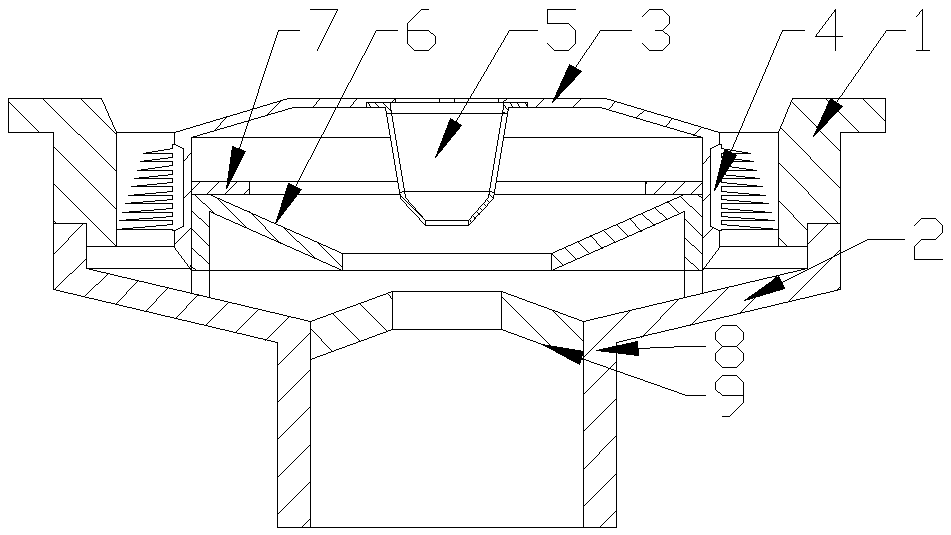

[0018] The present invention will now be described in further detail with reference to the drawings. These drawings are all simplified schematic diagrams, which merely illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0019] Such as figure 1 As shown, the present invention is a floor drain, including a mounting ring, a drain pipe is connected to the lower end of the mounting ring through a tapered tube, and a support is coaxially fixed on the inclined inner wall of the tapered tube Ring, a drainage opening is further provided at the fixed position of the support ring and the inner wall of the reducer; a separation assembly is connected to the support ring, and the separation assembly includes a cylindrical separation housing, the separation housing The bottom of the separation shell is an open structure, and a high-speed separator is provided in the middle of the closed end of the sepa

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap