Corynebacterium glutamicum for producing gamma-aminobutyric acid, and building method and application thereof

A technology of Corynebacterium glutamicum and aminobutyric acid, applied in the field of genetic engineering, to achieve the effect of reducing production costs and high-efficiency production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

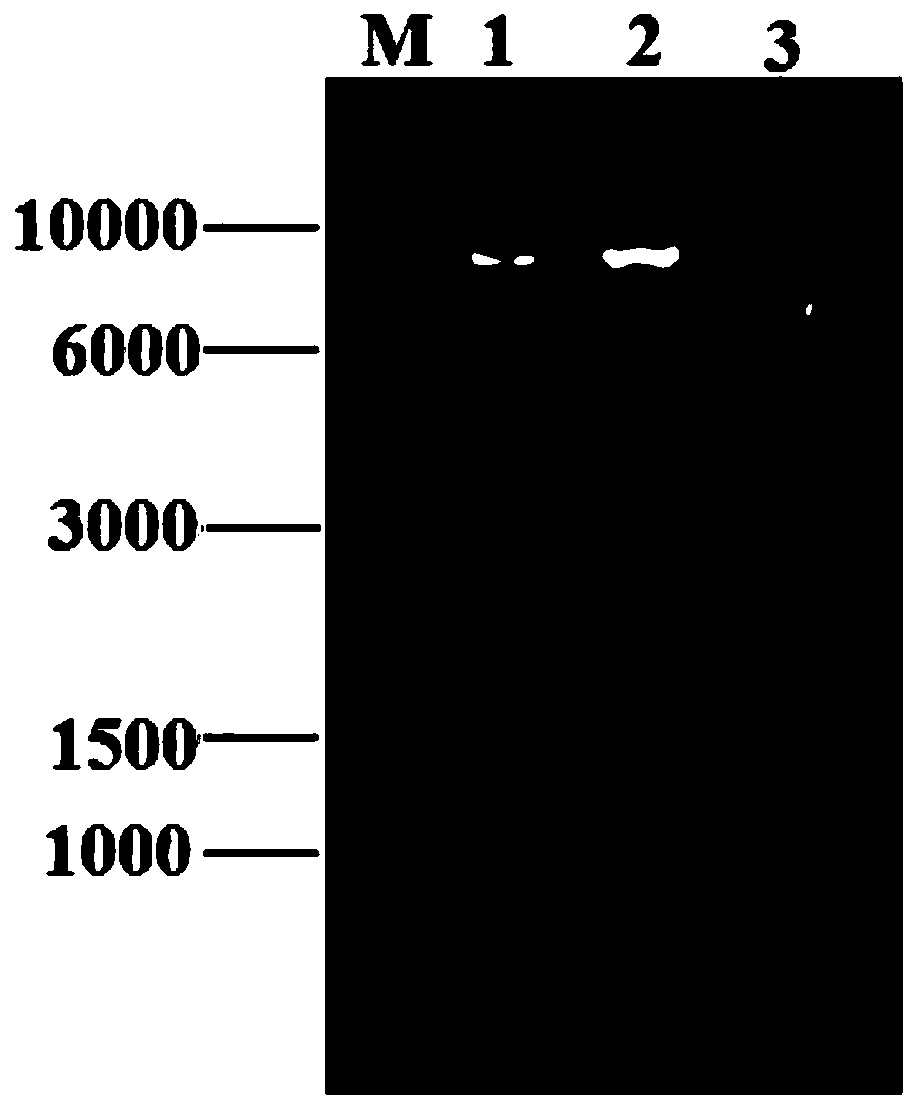

Image

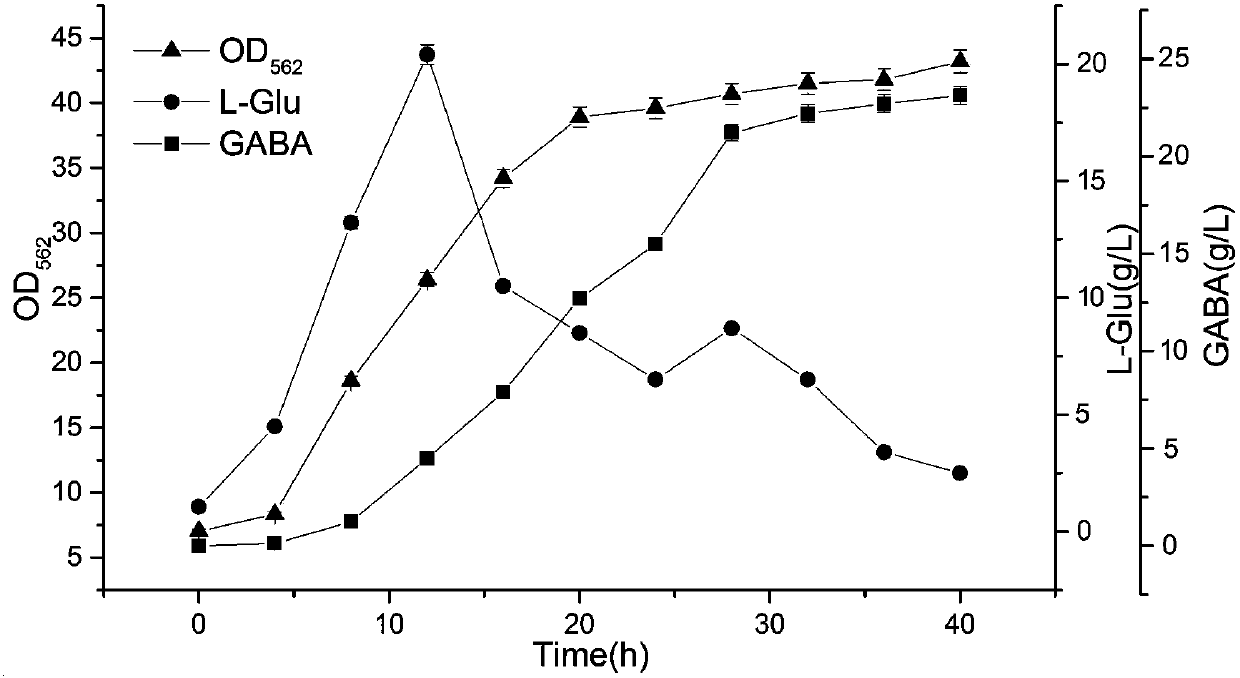

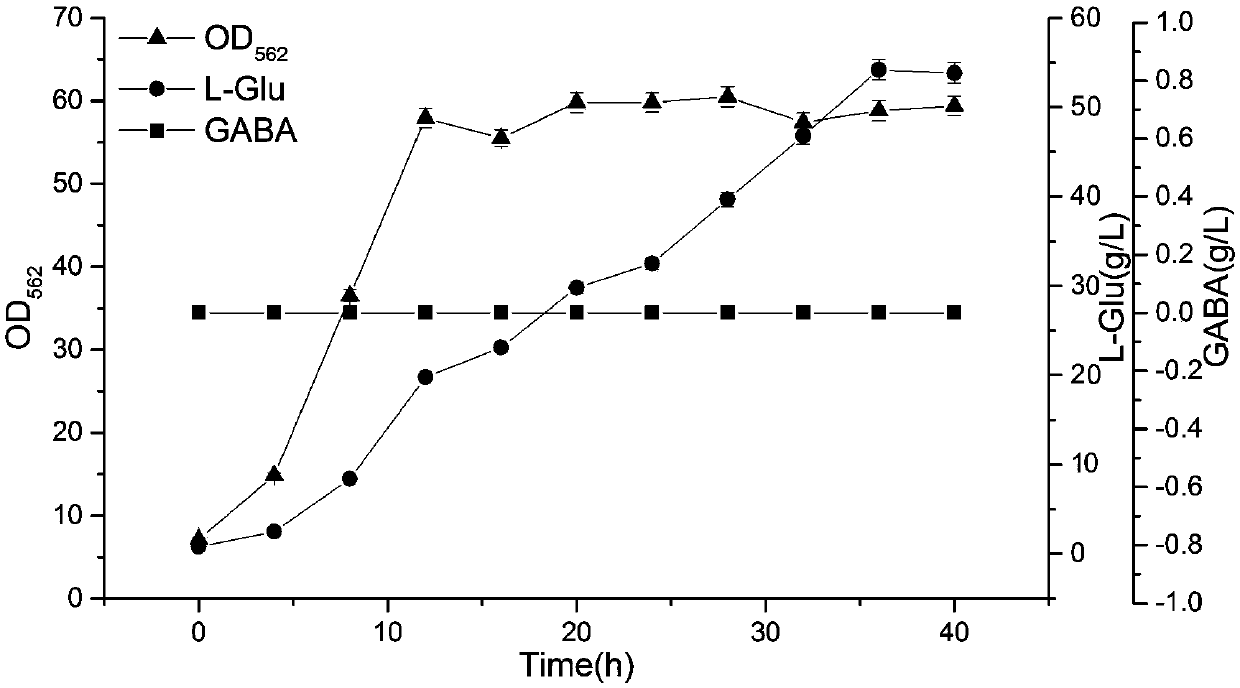

Examples

Embodiment Construction

[0060] A method for constructing a Corynebacterium glutamicum producing γ-aminobutyric acid, comprising the steps of:

[0061] (1) Design of primers

[0062] According to the glutamic acid dehydrogenase gdh gene sequence design PCR required primer P1gdh and P2gdh of the corynebacterium glutamicum bacterial strain registered in gene database GenBank; The gene sequence of described primer P1gdh is CG GAATTC ATGACAGTTGATGAGCAGGTCT, wherein the underline is the enzyme cutting point of EcoRI; the gene sequence of the primer P2gdh is GC GTC GAC TTAGATGACGCCCTGTGCCAGCA, where the underline is the restriction site of sal Ⅰ;

[0063] According to the glutamic acid decarboxylase gadB gene sequence design PCR required primer P1gadB and P2gadB of the lactobacillus plantarum strain registered in gene database GenBank; The gene sequence of described primer P1gadB is: CG GAATTC ATGGCAATGTTATACGGTAAAC, wherein the underline is the enzyme cutting point of EcoRI; the gene sequence of the primer

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap