Power support tower with heat dissipation structure, and working method of power support tower

A technology of heat dissipation structure and tower, which is applied to towers, electrical components, substation/distribution device casings, etc., can solve the problems of limited use stability and heat dissipation performance, affecting applicability and practicability, and achieves compact and practical structure. Good performance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

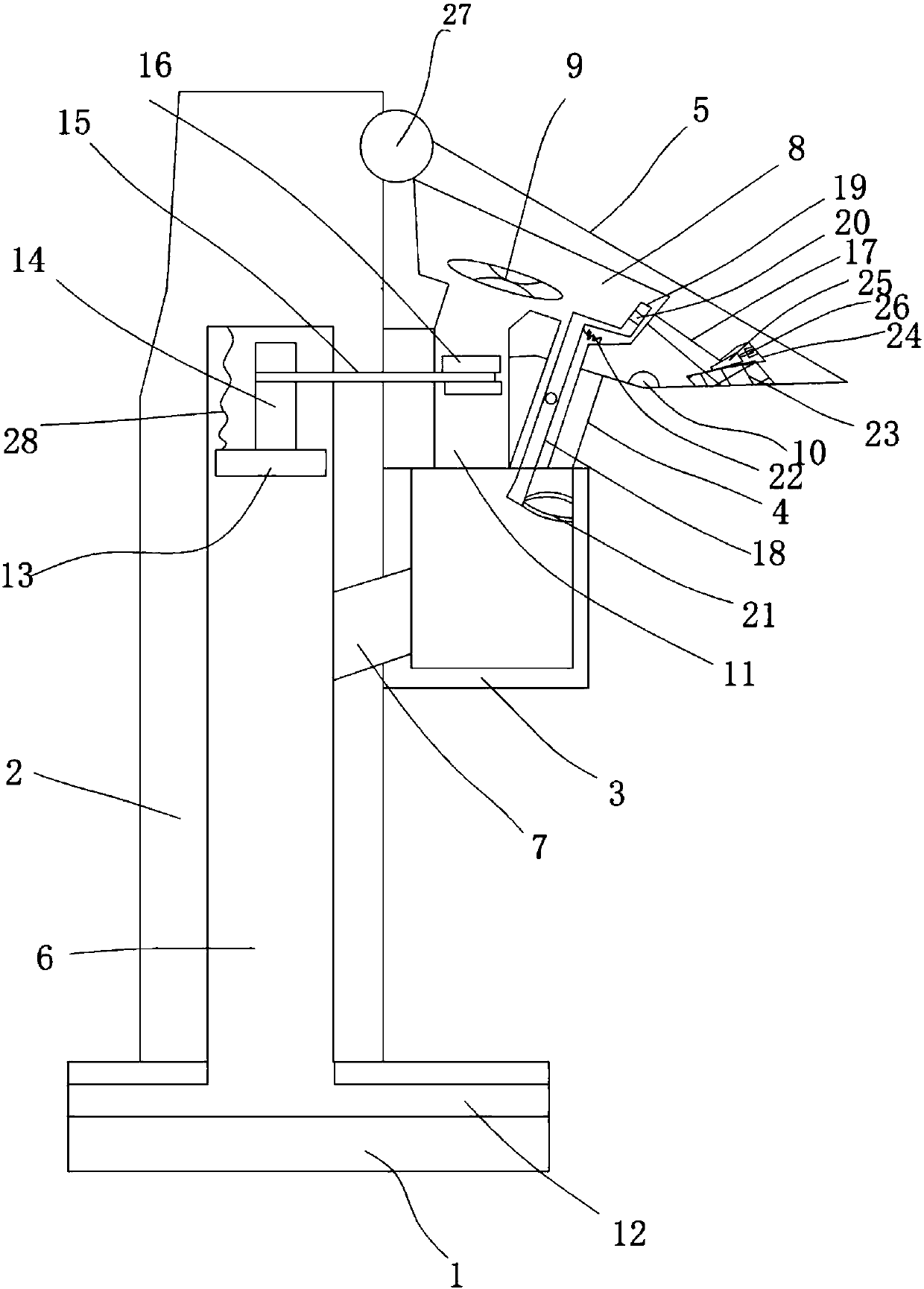

[0019] Example 1

[0020] Such as figure 1 The illustrated power supporting tower with a heat dissipation structure includes a base 1, a tower main body 2 arranged on the base 1, and a power box 3 fixed on the tower main body 2, on the top of the power box 3 A vertical support rod 4 is provided, a top cover 5 is fixed on the top of the vertical support rod 4, a heat dissipation cavity 6 is provided in the tower main body 2, and a side wall of the tower main body 2 is provided with The inner cavity of the power box 3 is connected with a heat dissipation pipe 7 and one end of the heat dissipation pipe 7 extends into the heat dissipation cavity 6. An air cavity 8 is provided in the top cover 5, and an air cavity 8 is provided in the air cavity 8 The fan 9 and the power interface 10 connected to the fan 9, an air duct 11 connecting the air cavity 8 and the inner cavity of the power box 3 is provided in the vertical support rod 4, and the base 1 is provided with the The heat dissipatio

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap