Secondary mortar mixing device for dry-mixed mortar

A dry-mixed mortar and slurry mixing technology, which is applied in the direction of clay preparation equipment, cement mixing equipment, chemical instruments and methods, etc., can solve the problems of safety, local solidification, waste of resources, etc., and achieve easy transportation, prevent local solidification, and avoid The effect of wasting resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

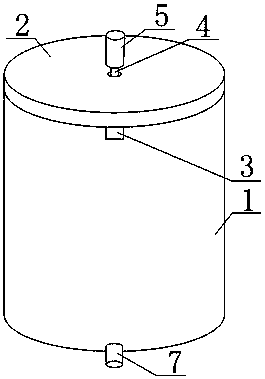

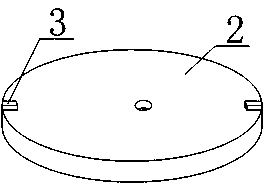

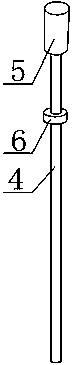

[0017] Such as figure 1 , figure 2 and image 3 As shown, the secondary mixing device for dry-mixed mortar includes a cylinder 1, a cover 2 and a mixing rod 4, wherein a gap is provided at the top of the side wall of the cylinder 1, and the cover 2 closes the bottom of the cylinder 1. The upper end is open, and the lower end surface of the cover 2 is connected with a positioning protrusion 3, the positioning protrusion 3 corresponds to the gap position of the cylinder body 1, and the size and shape match, and the cylinder body 1 and the cover 2 are inserted into the cylinder body through the positioning protrusion 3 1 for connection. The central part of the cover 2 is provided with a circular perforation, the mixing rod 4 passes through the circular perforation of the cover 2, and the lower end of the mixing rod 4 is in contact with the inner bottom of the cylinder body 1 .

[0018] In order to facilitate construction personnel to control the mixing rod 4, the upper end of th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap