Auxiliary support for U-shaped pipe welding

A technology of auxiliary bracket and U-shaped tube, applied in welding/cutting auxiliary equipment, auxiliary device, welding equipment, etc., can solve the problem of high cost and achieve the effect of simple structure and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

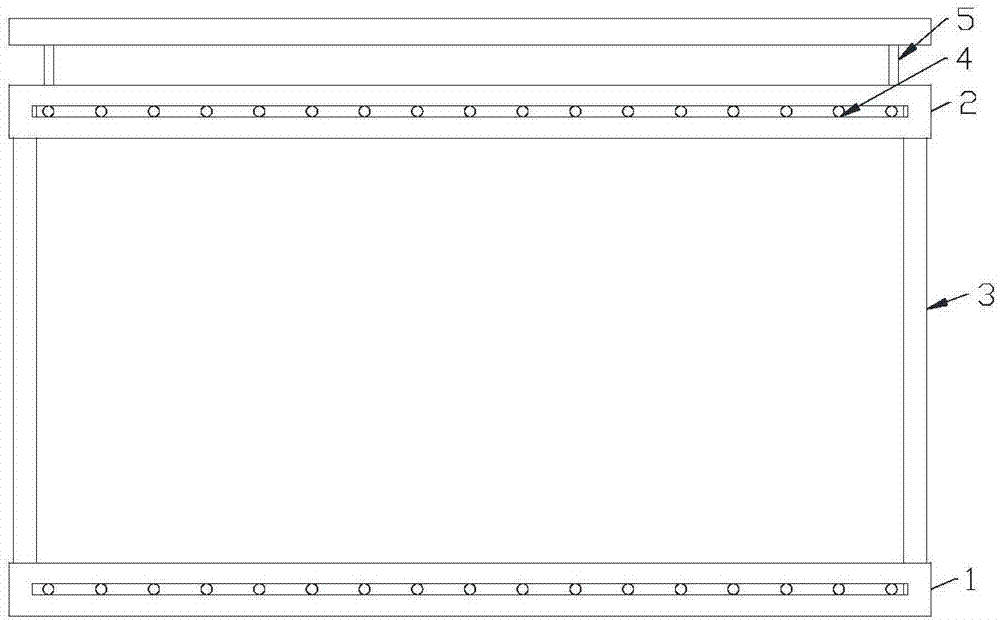

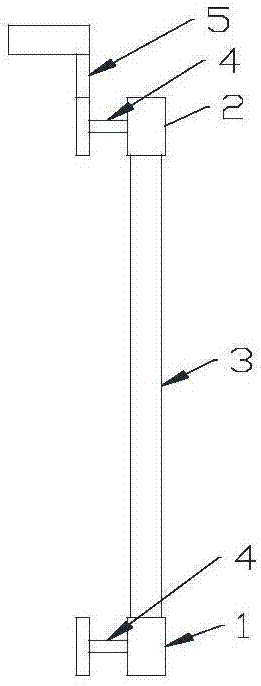

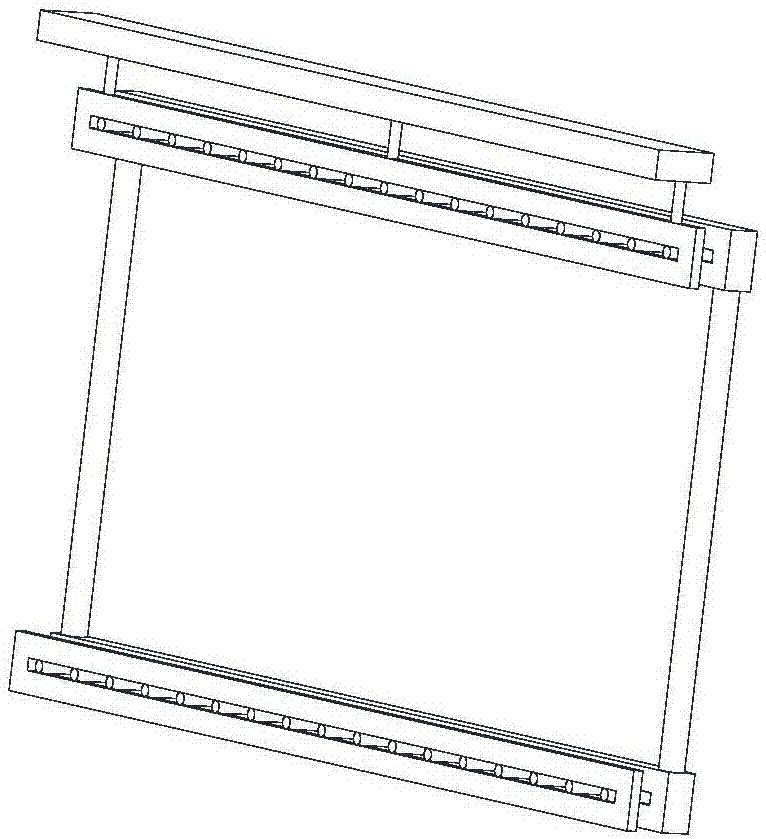

[0011] As shown in the figure, a U-shaped tube welding auxiliary support includes an upper beam 1, a lower beam 2, the upper beam 1 and the lower beam 2 are connected by columns 3 on both sides; the upper beam 1 is driven by an internal stepping motor Slide up and down on the column 3; the upper cross beam 1 and the lower cross beam 2 are divided into two parts along the horizontal direction, and the middle is connected by a connecting rod 4, and the beam is divided into two steps. The opposite sides of the beam are parallel to the vertical surface and the surface Smooth, the connecting rod 4 is driven by the stepping motor in the beam to adjust the spacing, which is used to fix the U-shaped tube to be welded in the width direction; the one side beam connected by the connecting rod 4 can move along the connecting rod to adjust the distance between the two side beams The spacing is used to fix the position in the thickness direction of the U-shaped tube.

[0012] A smooth horizontal

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap