Energy supply circuit for a lighting module

A lighting module and energy supply technology, which is applied to lighting devices, lighting and heating equipment, electric light sources, etc., can solve the problems of reduced service life of light sources, and achieve the effect of reducing loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

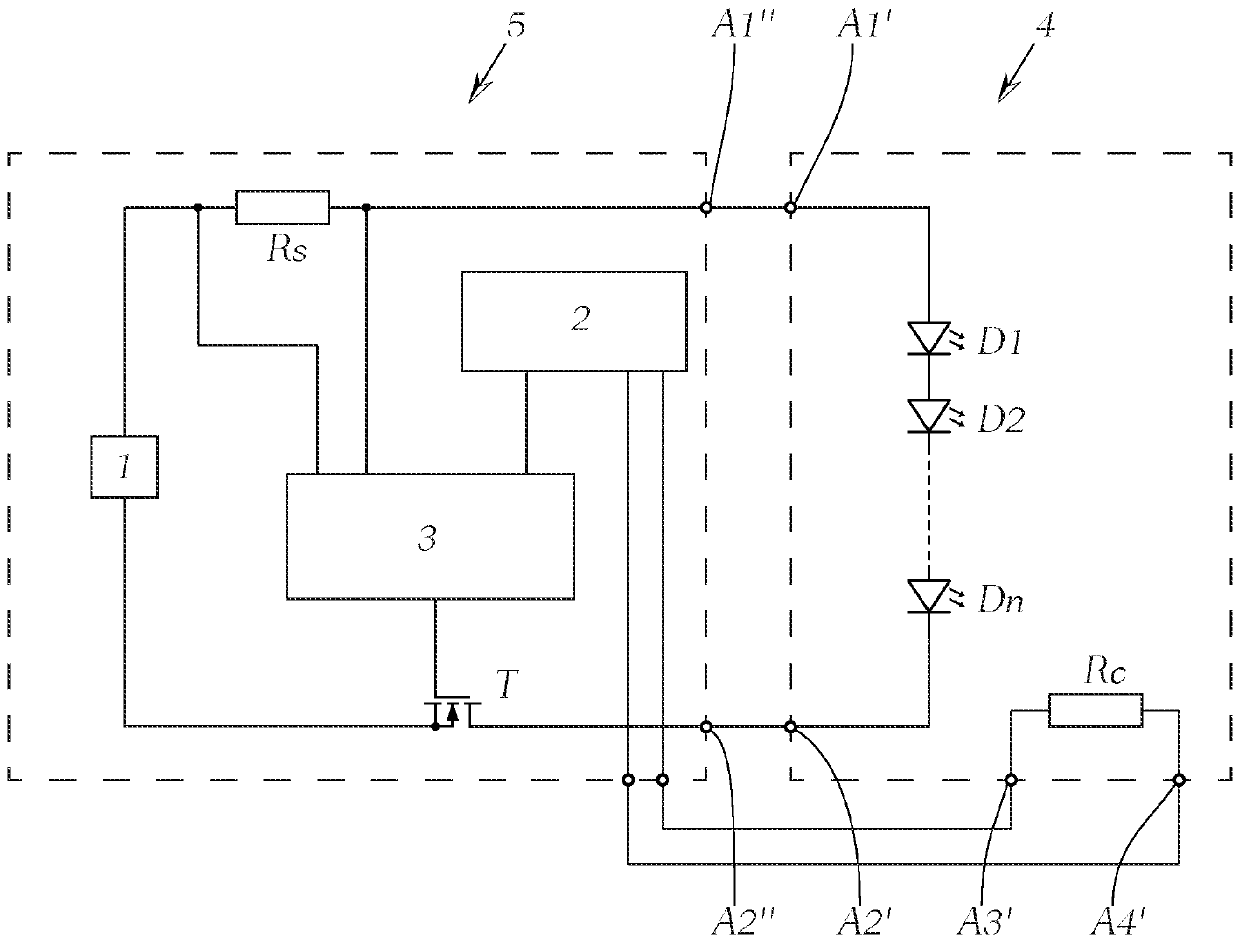

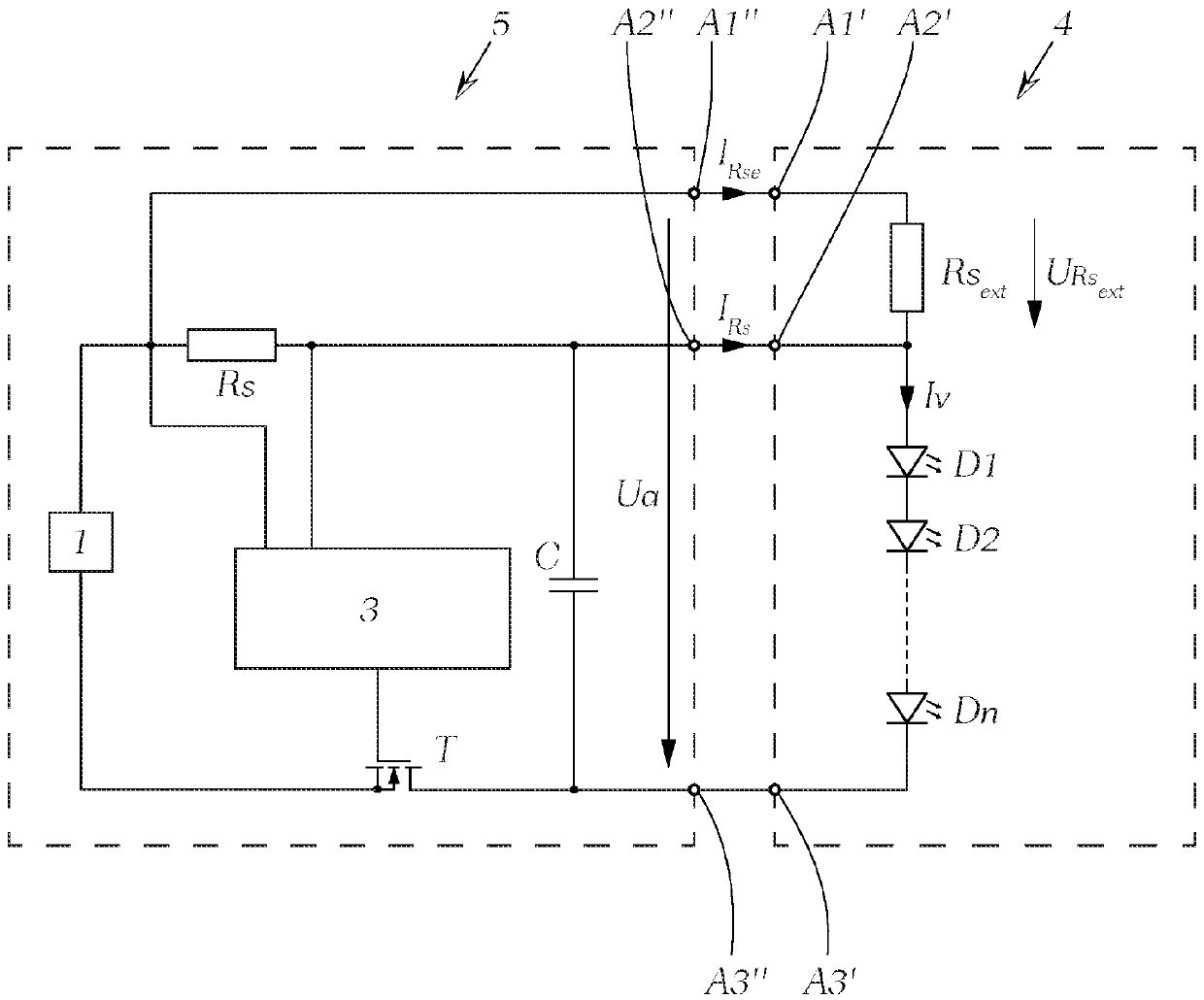

[0024] figure 1A schematic diagram of a circuit arrangement according to the prior art is shown. The circuit arrangement comprises a lighting module 4 and an energy supply circuit 5 for supplying power to the lighting module 4 . As described at the outset, the lighting module 4 has a plurality of light sources D1 , D2 to Dn, which can be passed via the corresponding connection terminal A1 of the energy supply device 5 via the connection terminals A1 ′ and A2 ′ " and A2" to power. The lighting module has a coding resistor Rc which can be contacted and evaluated by the evaluation unit 2 arranged on the energy supply device 5 via specially designed terminals A3 ′ and A4 ′. Each brightness level is assigned a coding resistor, so that the brightness level of the lighting module 4 can be deduced by analyzing the resistance value and an appropriate supply current can be set. For this purpose, the evaluation unit 2 is connected to the regulation unit 3 . A power supply unit 1 , fo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap