Production process of heterogeneous embedded nutrient fine dried noodles

A production process and a heterogeneous technology are applied in the production process field of heterogeneous embedded nutritious noodles to achieve the effects of reducing the cost of raw materials, increasing the selling price and improving the nutritional value of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Determination of the parameters of the noodle interlayer flour sheet

[0030] 1. Determination of the parameters of interlayer flour noodles

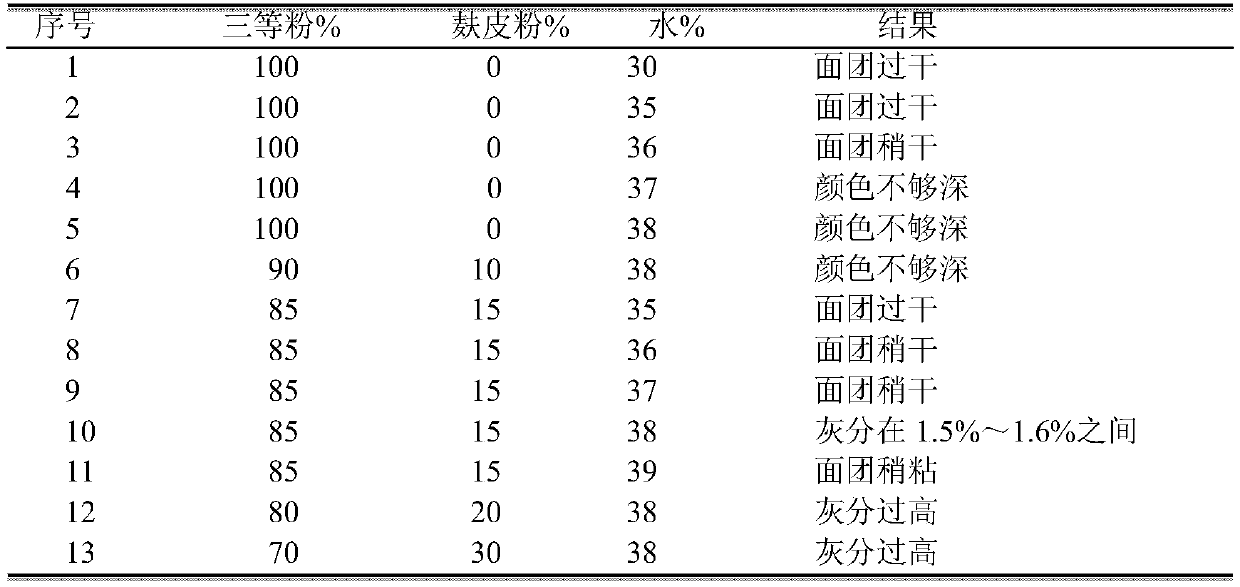

[0031] Table 1 Determination of the parameters of interlayer flour noodles

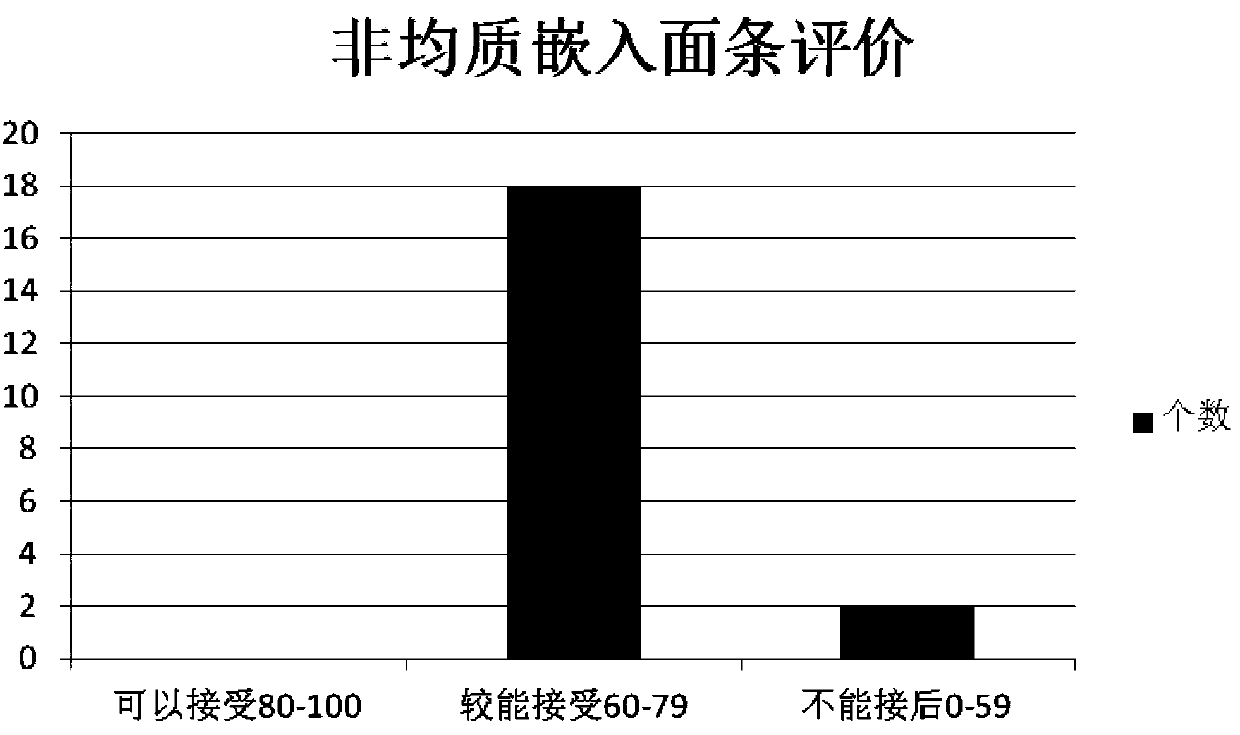

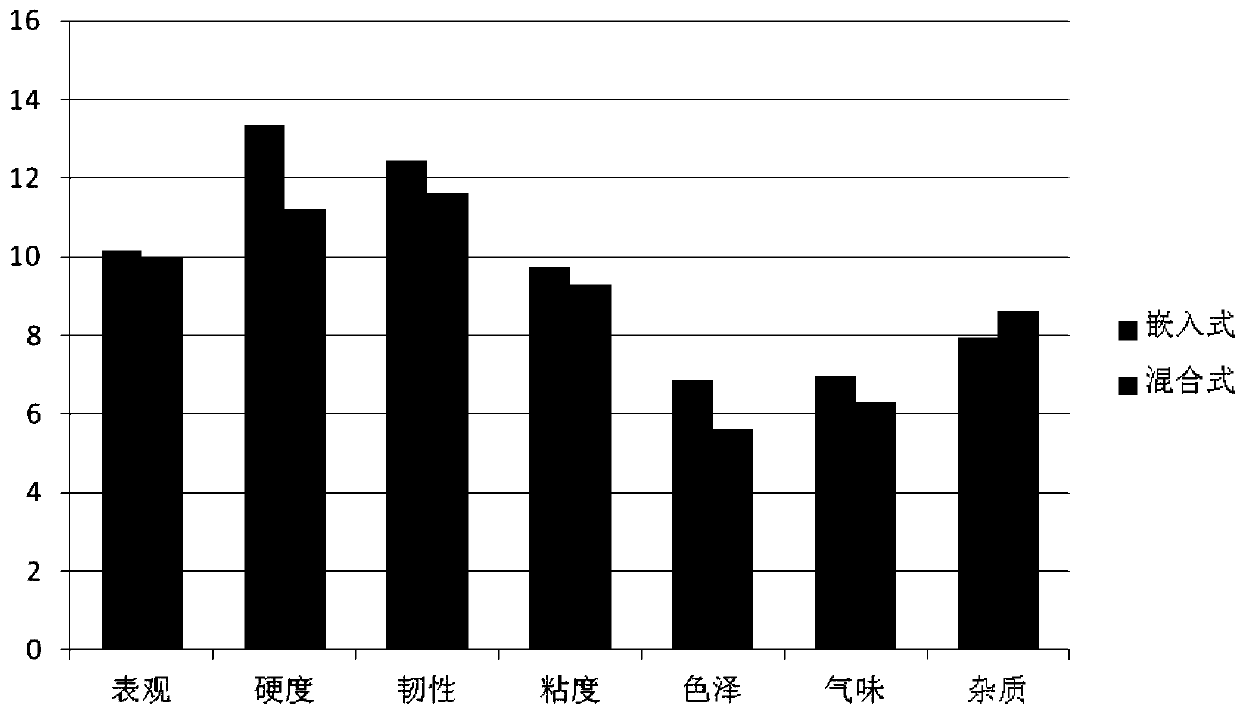

[0032]

[0033] As shown in Table 1, the flour of the interlayer flour sheet is optimized by mixing 85% third-class flour and 15% bran flour, and the amount of water added to the dough is preferably 38% of the mass of the mixed flour.

[0034] 2. Determination of the embedded thickness ratio of the interlayer

[0035] Table 2 Determination of embedded thickness ratio

[0036]

[0037] As shown in Table 2, the optimal ratio of interlayer embedding thickness is 2:3:2, because if the thickness of the interlayer is too high, it will affect its taste, and if the thickness of the interlayer is too low, it will not be obvious that there is an interlayer in the middle.

[0038] 3. Physical and chemical indicators of dried noodles

[0039] Table 3 physi

Embodiment 2

[0095] A production process for heterogeneously embedded nutritional fine noodles, comprising the following steps:

[0096] 1) Grind the bran into powder, and pass the third-class powder, first-class powder and bran powder through a 100-mesh sieve respectively. Prepare the dough with water in advance, dissolve the refined salt with warm water and mix it with water. The amount of table salt is 1% of the weight of the flour. Then put the first-class powder into the dough mixer, start the dough mixer, add water, and the dough mixer time is 15 minutes. Then put the third-class flour and bran powder into the dough mixer according to the mass ratio of 85:15, start the dough mixer, after the two flours are evenly mixed, add water with 38% of the flour mass, and the dough mixing time is 15 minutes.

[0097] 2) Primary ripening: the dough obtained in step 1) is cooked for the first time; the ripening time is 15 minutes.

[0098] 3) Tablet pressing: the dough after the primary aging is p

Embodiment 3

[0102] A production process for heterogeneously embedded nutritional fine noodles, comprising the following steps:

[0103] 1) Mix the third-class flour and bran powder at a mass ratio of 90:10, add 40% water of the mixed powder mass to knead the dough; add the first-class flour and water to knead the dough.

[0104] 2) Primary ripening: the dough obtained in step 1) is cooked for the first time; the ripening time is 12 minutes.

[0105] 3) Tablet pressing: the dough after the primary aging is pressed into a dough sheet, wherein the third-class flour, bran powder and flour dough are used to press the interlayer flour dough; the first-class flour and flour dough is pressed into the outer layer A and the outer layer B noodles; the thickness of the interlayer powder noodles is 2mm, and the thickness of the outer A and outer B noodles is 2mm.

[0106] 4) Combination and secondary aging: insert the interlayer powder dough sheet between the outer layer A and outer layer B dough sheets

PUM

| Property | Measurement | Unit |

|---|---|---|

| Extensibility | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap