Eco-friendly sewage high-efficiency pressure filtration treatment device

An environmentally friendly sewage and treatment device technology, which is applied in water/sewage treatment, degassed water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of difficulty in meeting the requirements of small and medium-sized enterprises, high cost, and large energy consumption. , to achieve the effect of improving environmental safety, improving efficiency, improving processing efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

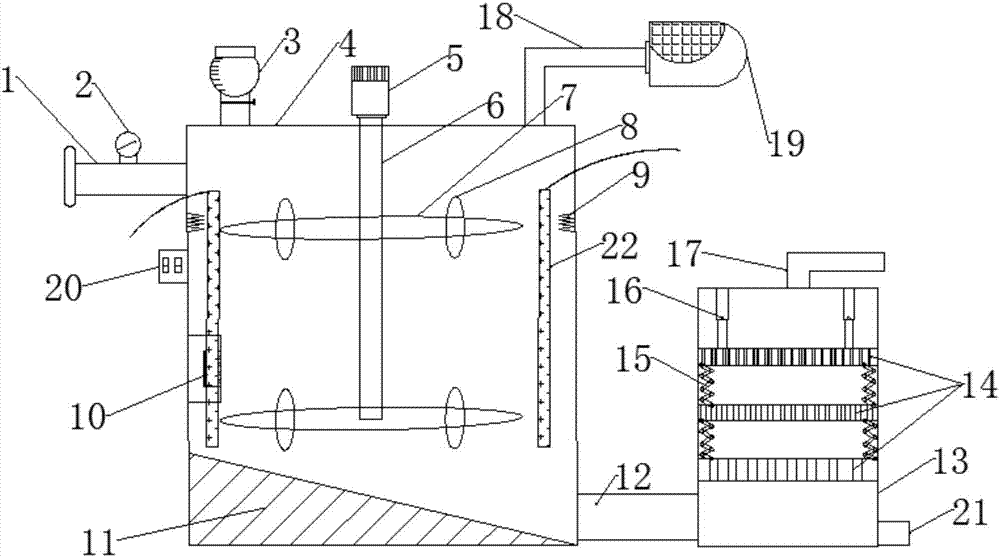

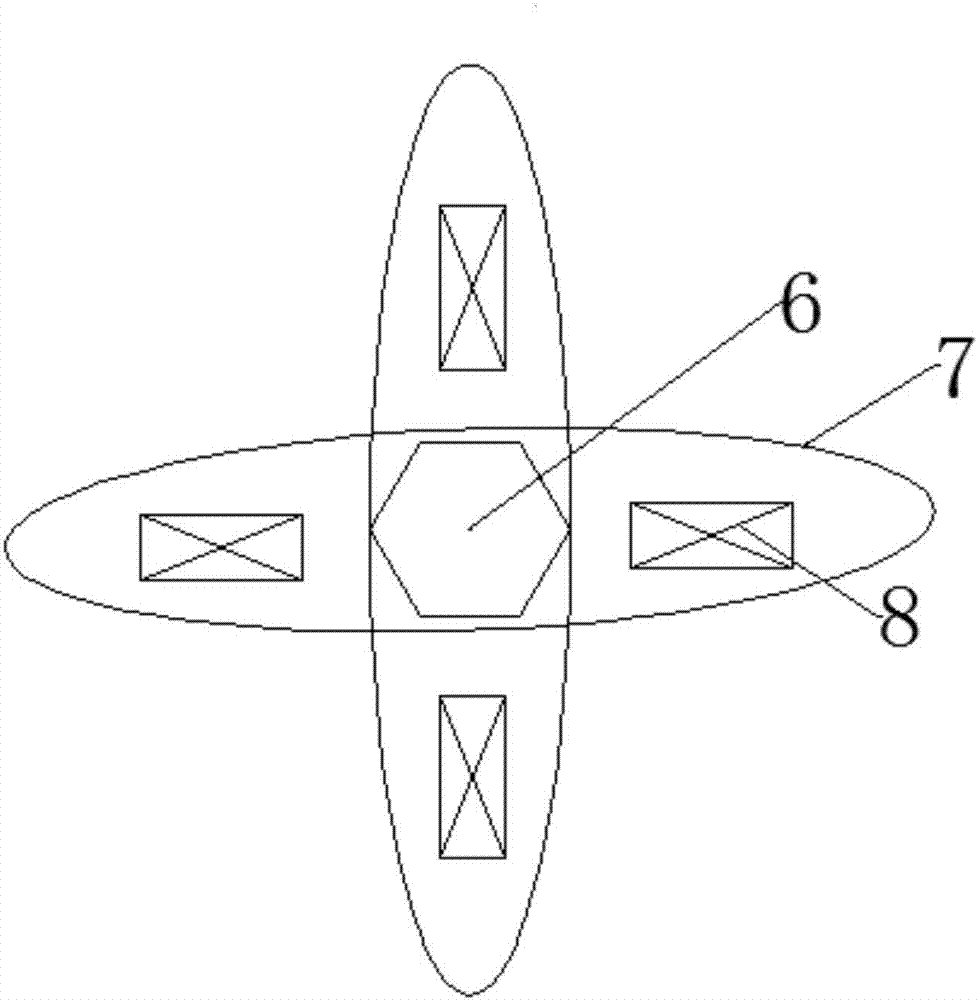

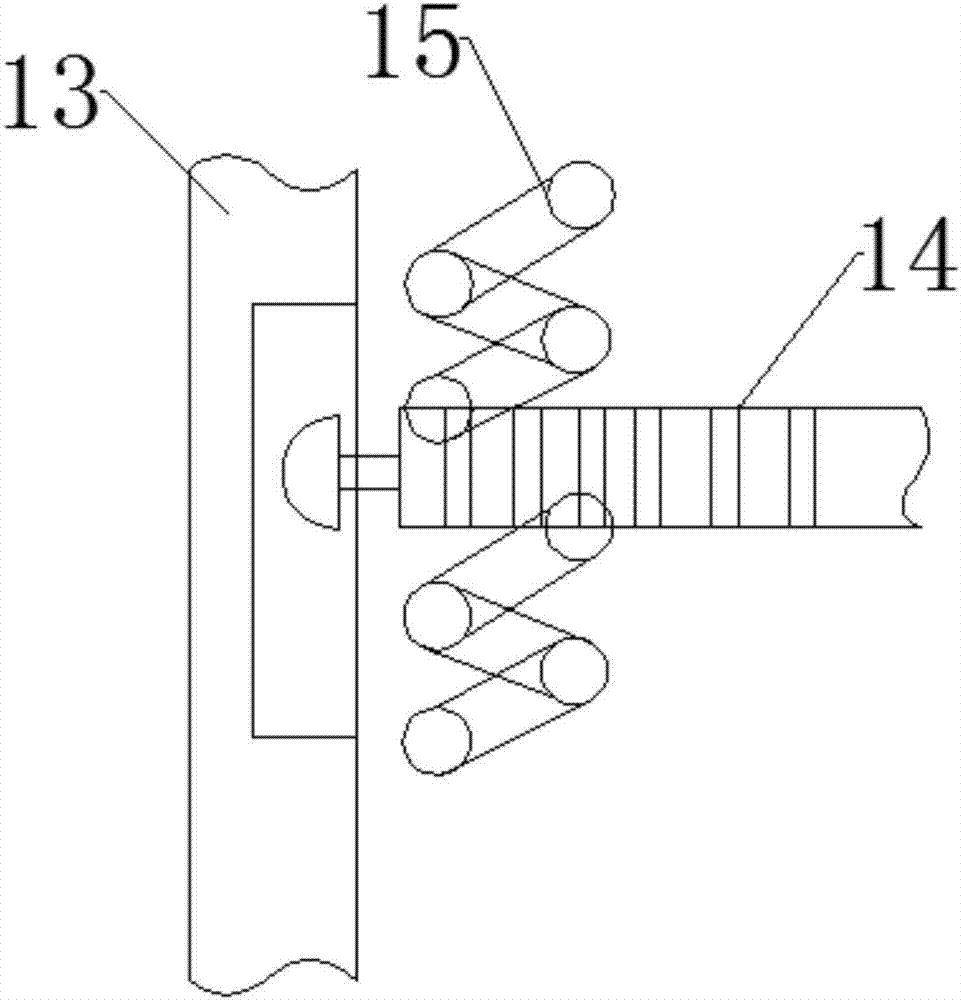

[0018] see Figure 1-3 , a high-efficiency filter press treatment device for environmentally friendly sewage, comprising a water inlet pipe 1, a chemical addition pipe 3, a treatment box 4, a stirring motor 5, a rotating shaft 6, a stirring impeller 7, auxiliary stirring blades 8, defoaming spikes 9, and a heater 10 , filter press box 13, filter plate 14, spring 15, electric telescopic rod 16, water outlet pipe 17, gas collection tank 19, impurity discharge pipe 21 and ionization rod 22, the top side wall of described treatment box 4 is connected with water inlet pipe 1 , a flow meter 2 is installed on the water inlet pipe 1, and the flow meter 2 records the amount of water entering the treatment box 4, so as to ensure an appropriate amount of water to be treated at one time, avoid too much or too little affecting the treatment of sewage, and improve

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap