Microwaveable coated food product and method of manufacture

A microwave heating and coating technology, applied in microwave ovens, equipment for performing this method, and bread crumb coating products, can solve problems such as drying, reduce fat intake and retention, improve taste and taste, enhance crispy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0176] In the pre-processing stage, pieces of chicken or other substrates are cut to size or comminuted as required. The matrix pieces were impregnated with the stabilizer ingredients as described in Examples 1 and 2. The product is shaped using a forming machine. A conventional forming machine may be arranged to extrude pieces of chicken substrate having a predetermined thickness and one or more shapes. The pieces were extruded on a conveyor belt arranged to deliver them to a tempura ladle containing an aqueous coating composition, as described in Example 3, to form a pre-coated product.

[0177] The main aqueous coating is applied using tempura coating equipment. This includes storage tanks for the main aqueous coating composition or pre-gel. A first lower conveyor conveys the mass below the surface of the aqueous composition. The second upper conveyor prevents the blocks from floating. This ensures complete coating of the block. The upper and lower conveyor belts are arr

example 2

[0186] Example 2: Stabilizer Composition

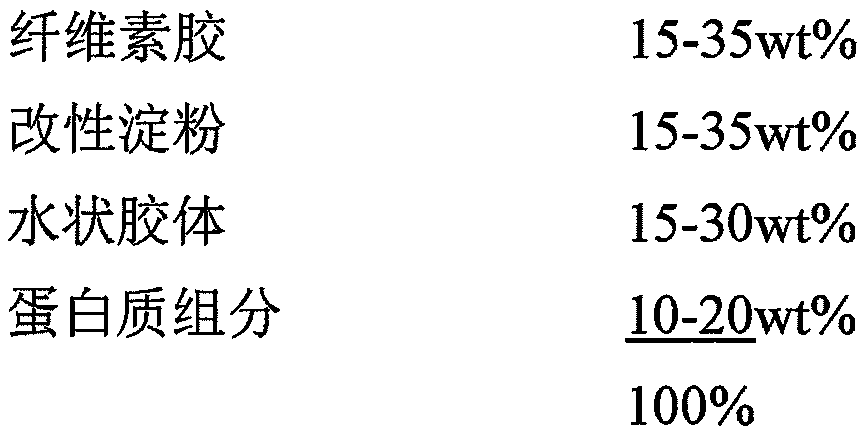

[0187] The stabilizer composition was prepared using the following ingredients:

[0188]

[0189] In use, the ingredients are dissolved in water to produce a solution having a concentration suitable to stabilize the particular substrate. For this, the dry powder mixture is partially hydrated in a basin and then poured into a chopper. Then, run the chopper for 2 to 3 minutes until the mixture is fully hydrated. The mixture can be hydrated directly in the chopper if required. Alternatively, the stabilizer can be hydrated using a high shear mixer equipped with a universal head.

[0190] Generic formulations can be adjusted to enhance their potency in specific matrices. The above formulation can be adjusted by adding citric acid (up to 1%) and ascorbic acid (up to 2%) with corresponding reductions in polydextrose (Litesse II (registered trademark)).

example 3

[0191] Example 3 - Impregnation of a substrate with a stabilizer component

[0192] A chicken mix for chicken strips or chicken nuggets was prepared using the following ingredients to be prepared as a dry mix, optionally using a hydration stabilizer component. The stabilizer of Example 1 was used.

[0193]

[0194] Chicken breasts were frozen to -3°C and smashed using a 10 mm plate. After crushing, the temperature was 0-3°C. Add water while mixing. While mixing, add the chicken whey including the following ingredients:

[0195]

[0196] Add the stabilizer according to Example 1 and allow to mix thoroughly. While mixing, add the rusks, and season to taste. Dry powder condiments are preferred. In use, this ingredient is dissolved in the water present in the matrix to form an aqueous stabilizer solution in situ.

[0197] A vacuum was drawn on the mixture to consolidate the structure, then the chicken mixture was frozen to -3°C and formed into shaped pieces.

[0198]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap