Tower-top-load-based independent variable-pitch control method for wind generating set

A technology for wind turbines and independent pitch adjustment, which is applied in the control of wind turbines, the monitoring of wind turbines, and wind turbines, etc., to achieve the effects of reduced number, easy process, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific examples.

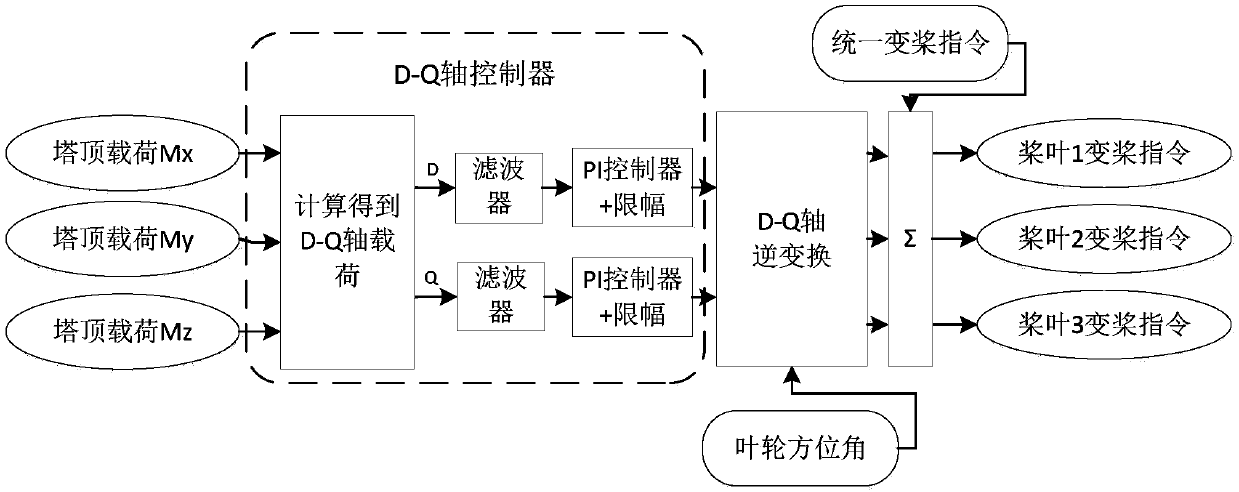

[0030] see Figure 4 As shown, the independent pitch control method for wind turbines based on tower top loads provided in this embodiment includes the following steps:

[0031] 1) First, mount the sensor on the top of the tower, and directly collect the bending moment M at the top of the tower through the sensor x , M y , M z , and then calculate the D-axis load and Q-axis load through the collected tower top load, that is, the D-Q axis load. The details are as follows:

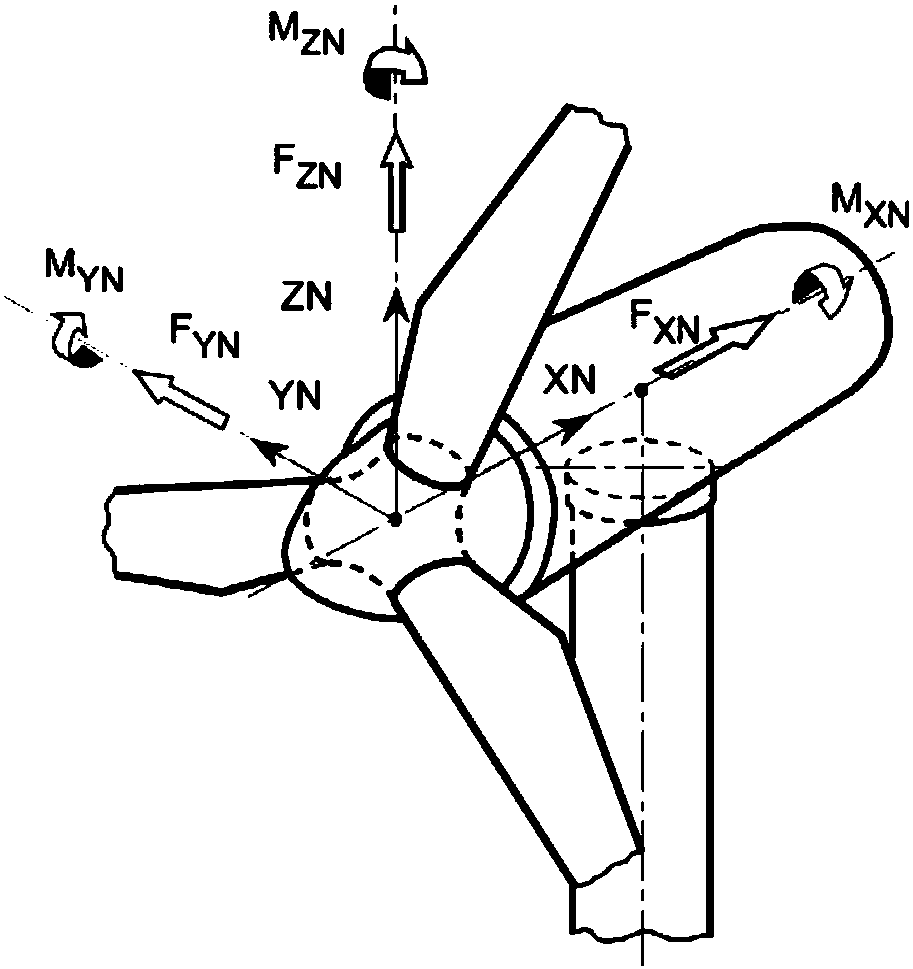

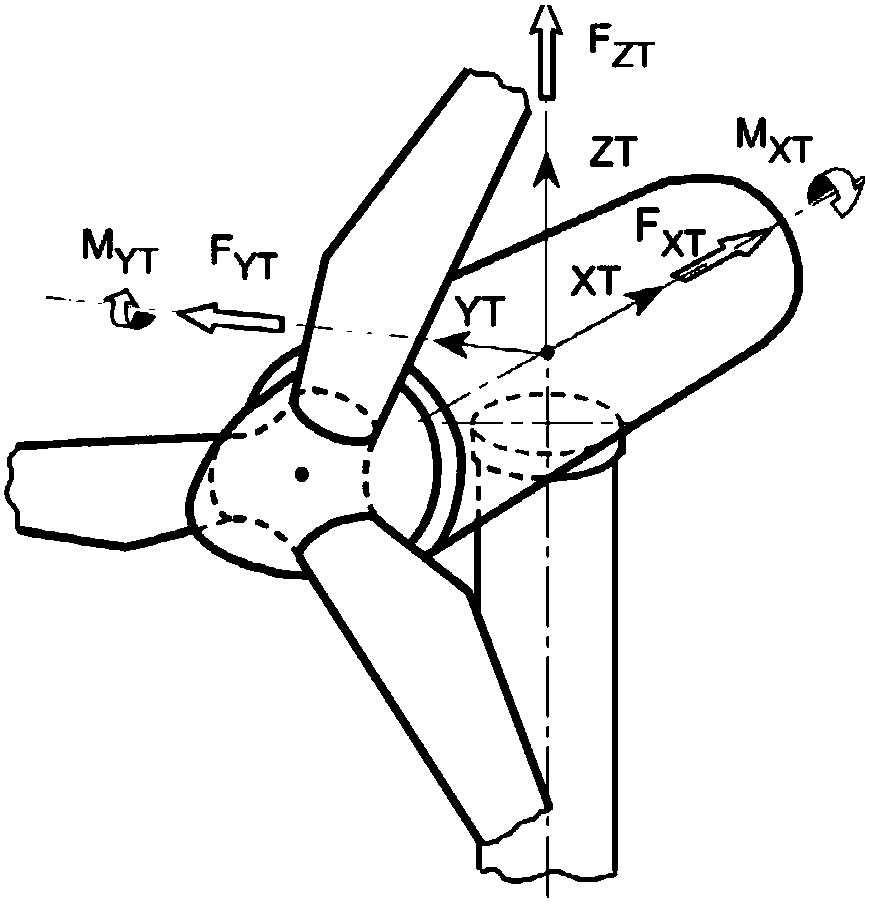

[0032] The D-axis load reflects the unbalance of the wind rotor plane pitch direction, and the Q-axis load reflects the unbalance of the impeller plane yaw direction load. In the wind turbine hub coordinate system, the D-axis load refers to the hub M y , while the Q-axis load refers to the hub M z . Hub coordinate system (GL coordinate system) The X coordinate axis points from the nose to the tail along

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap