Magnetic sensor for rotating electric machines

A technology of magnetic sensors and rotating electrical machines, applied in the field of magnetic sensors, can solve problems such as high cost and technical complexity, difficulty in detecting magnetic fields, and inaccurate sensor reading parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

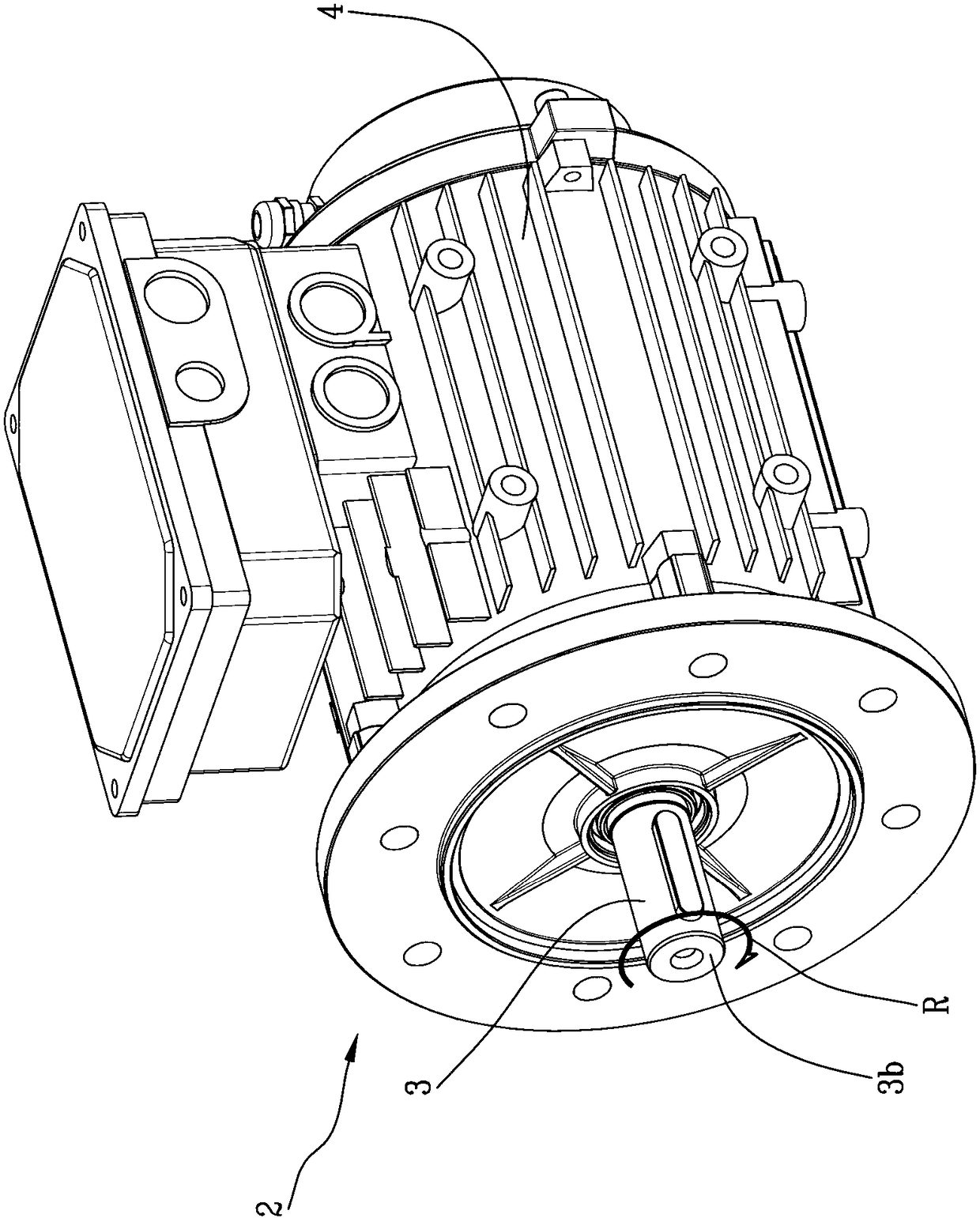

[0028] Referring to the drawings, 1 generally denotes a magnetic sensor for a rotating electrical machine 2 .

[0029] Spin Motor 2 is already in figure 1 shown in .

[0030] To illustrate the invention, the motor shaft 3 of the motor 2 and its frame 4 are shown.

[0031] The shaft 3 is configured to rotate in a rotary motion "R" and the frame 4 shown is configured to house all the components of the motor 2 which, as previously stated, are not essential to the description of the elements of the invention.

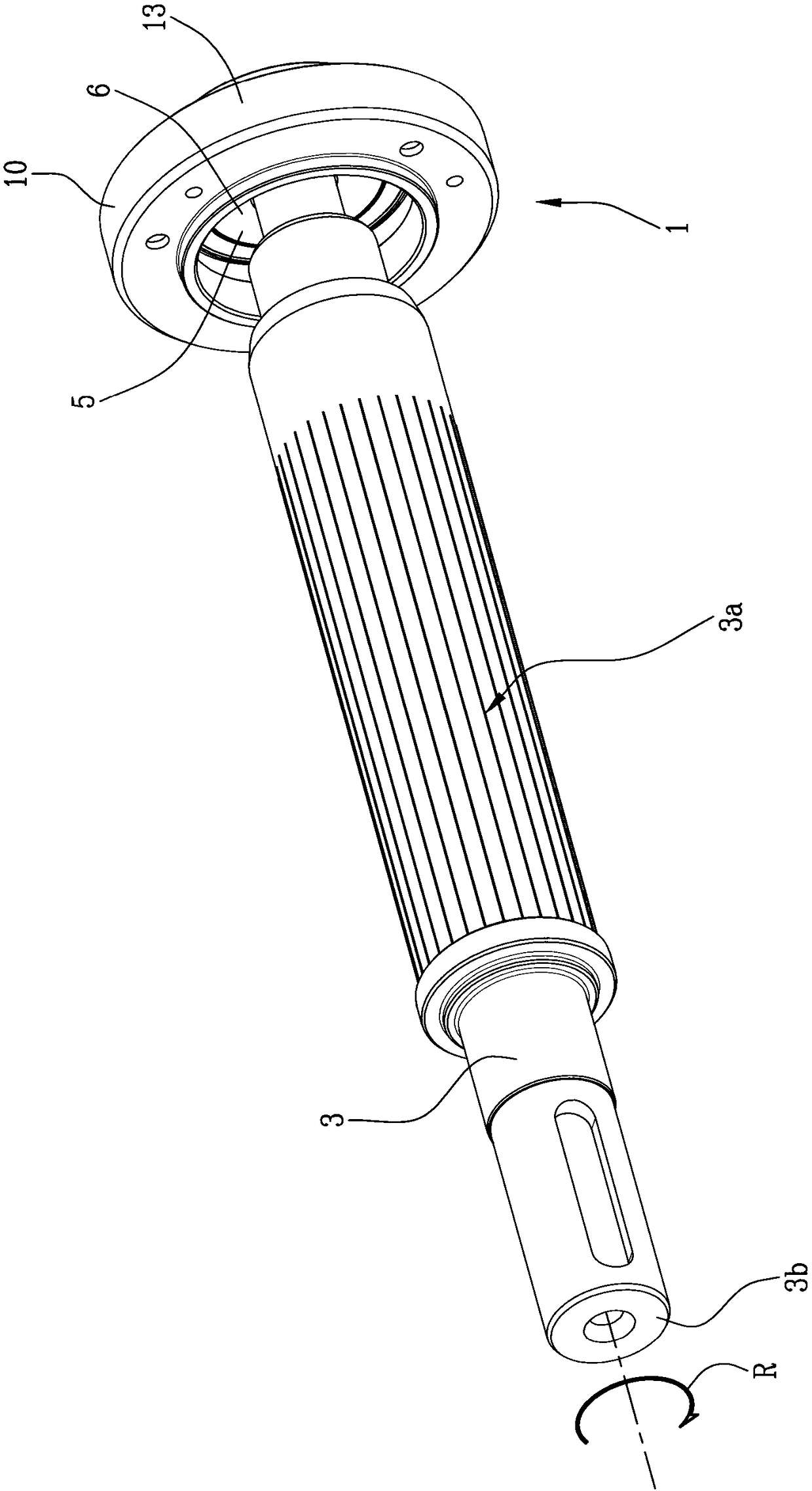

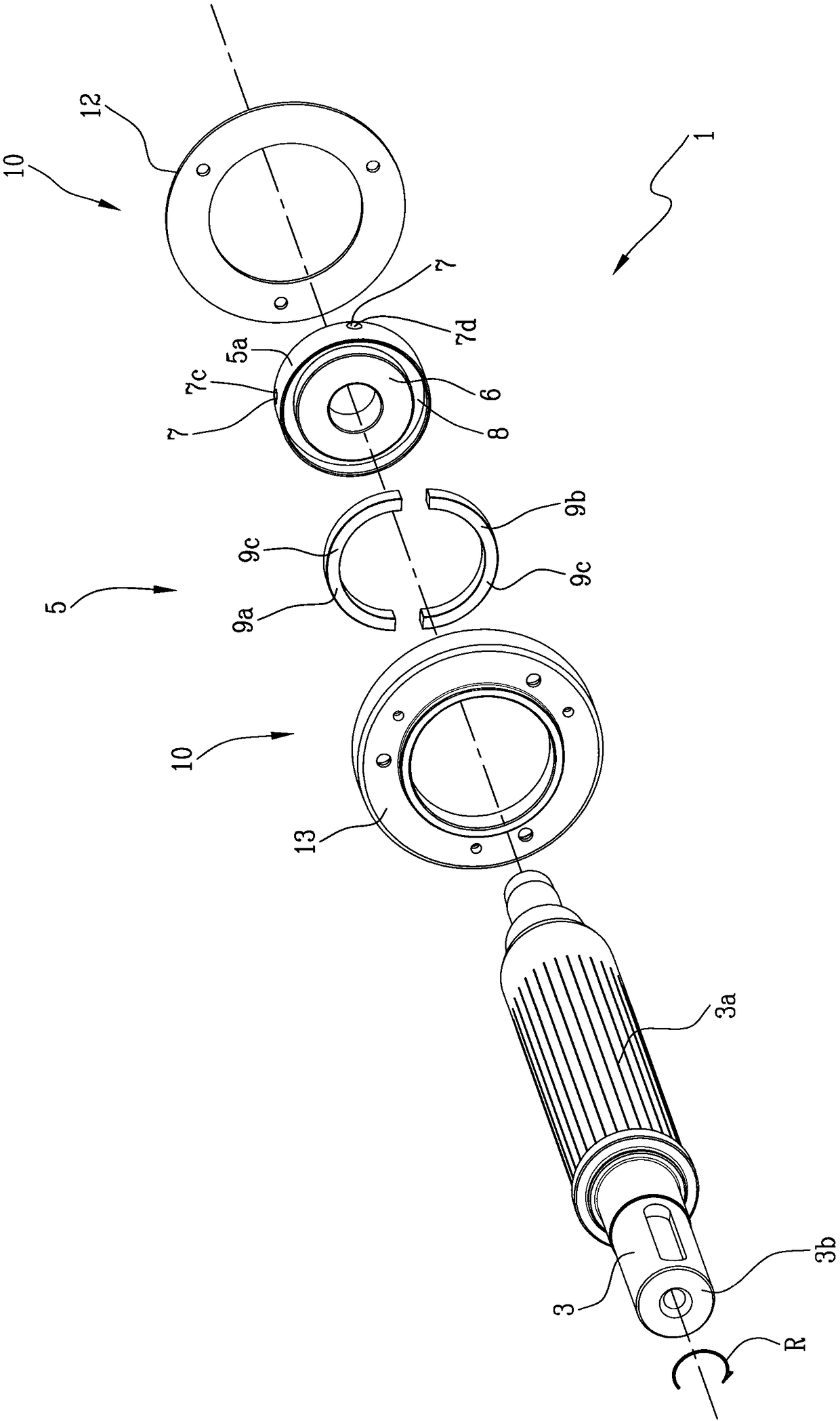

[0032] Such as figure 2 and image 3 As shown, the sensor 1 according to the invention is firmly mounted on the shaft 3 .

[0033] In particular, the sensor 1 comprises a rotating part 5 which, in use, is fixed to the side surface 3a of the shaft 3 . Preferably, the rotating part 5 of the sensor is fixed to the side surface 3 a at an intermediate point along the axis 3 . By an intermediate point is meant any point inside or outside the frame 4, preferably a point exc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap