Collecting frame for steel pipe production technical services

A production technology, a technology of steel pipes, applied in the field of technical services, can solve problems affecting the efficiency of steel pipe production, reduce the quality of steel pipes, increase production costs, etc., and achieve the effects of improving buffering effects, improving transportation efficiency, and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

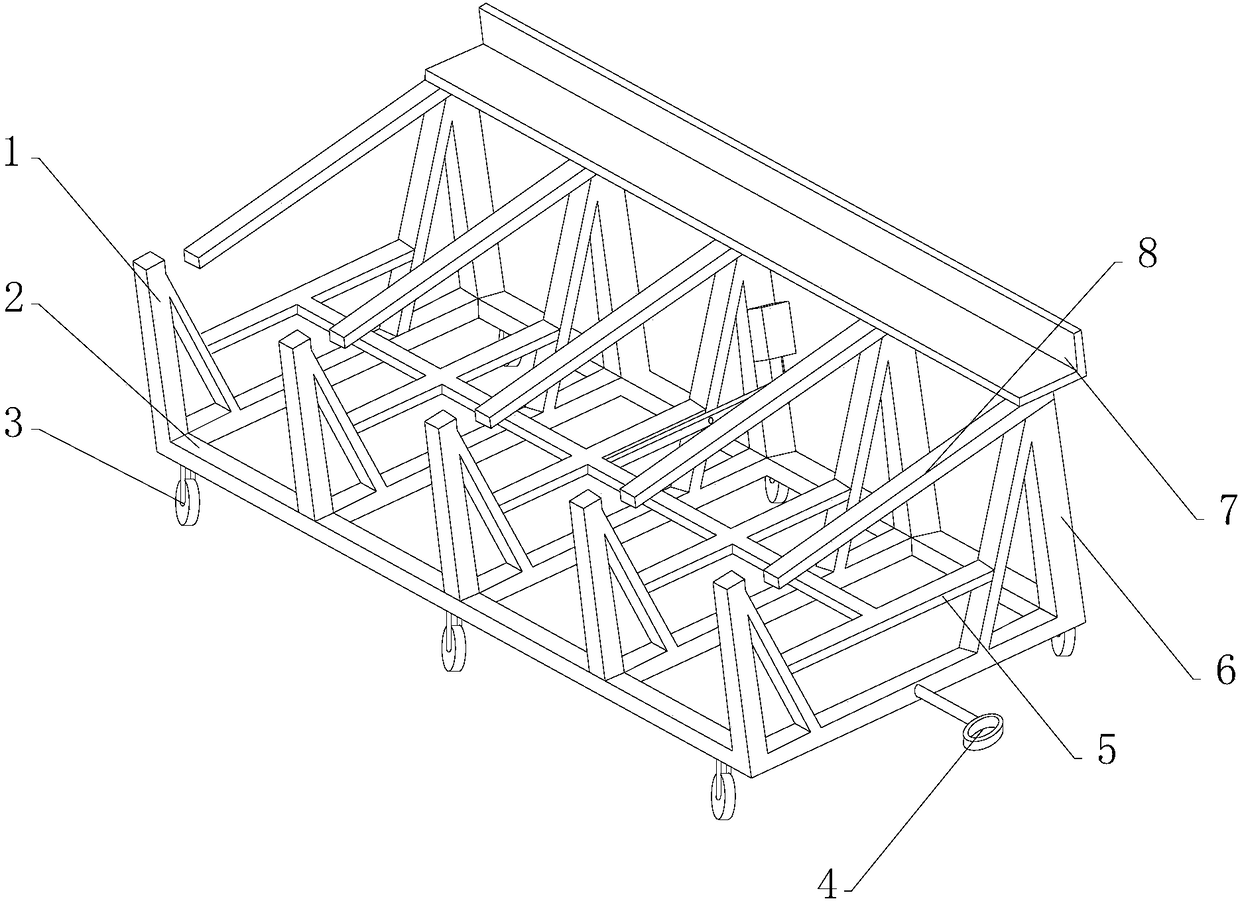

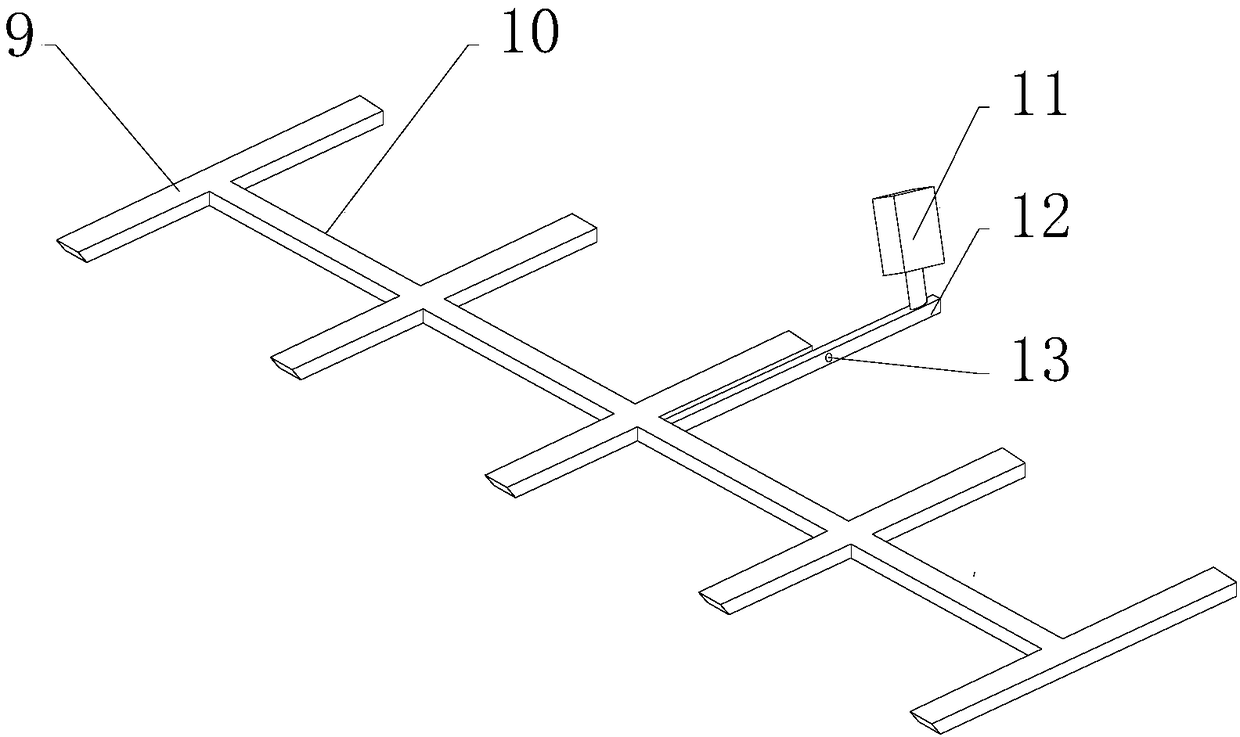

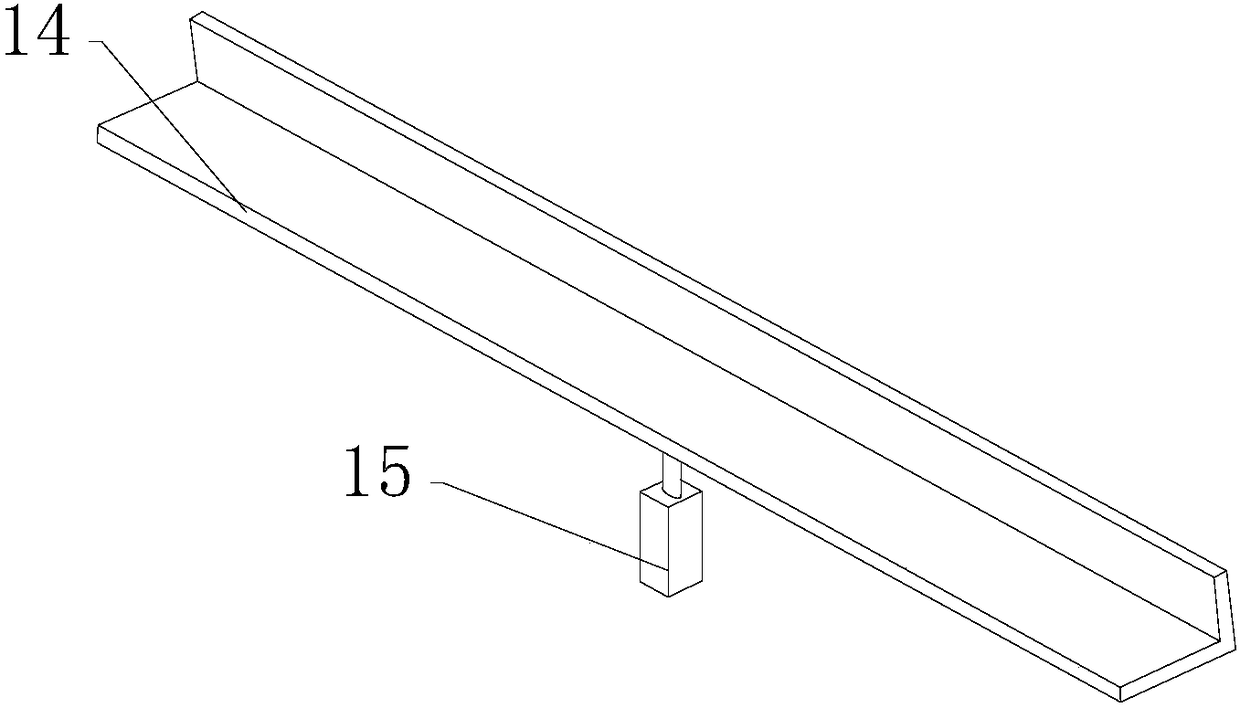

[0020] see Figure 1-Figure 4 , the present invention provides a technical solution: a collection frame for steel pipe production technical services, including a left retaining column 1, a base frame 2, a universal wheel 3, a connecting hook 4, a beam baffle mechanism 5, a right retaining column 6, Bearing mechanism 7 and guide bar 8, left retaining post 1 is provided with five, and five left retaining posts 1 are equidistantly installed on the upper end of the left part of base frame 2, and the lower end of base frame 2 is equidistantly equipped with six universal wheels 3, Connect hook 4 on the front end face of base frame 2, and right retaining post 6 is provided with five, and five right retaining posts 6 equidistantly are installed on the upper

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap