Active DFIG scheduling method based on maximal reactive power margin of wind power plant

A dispatching method and technology for wind farms, which are applied in wind power generation, electrical components, circuit devices, etc., and can solve the problems of coordinated control without considering active and reactive power, and failure to fully utilize the reactive power generation capability of DFIG.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

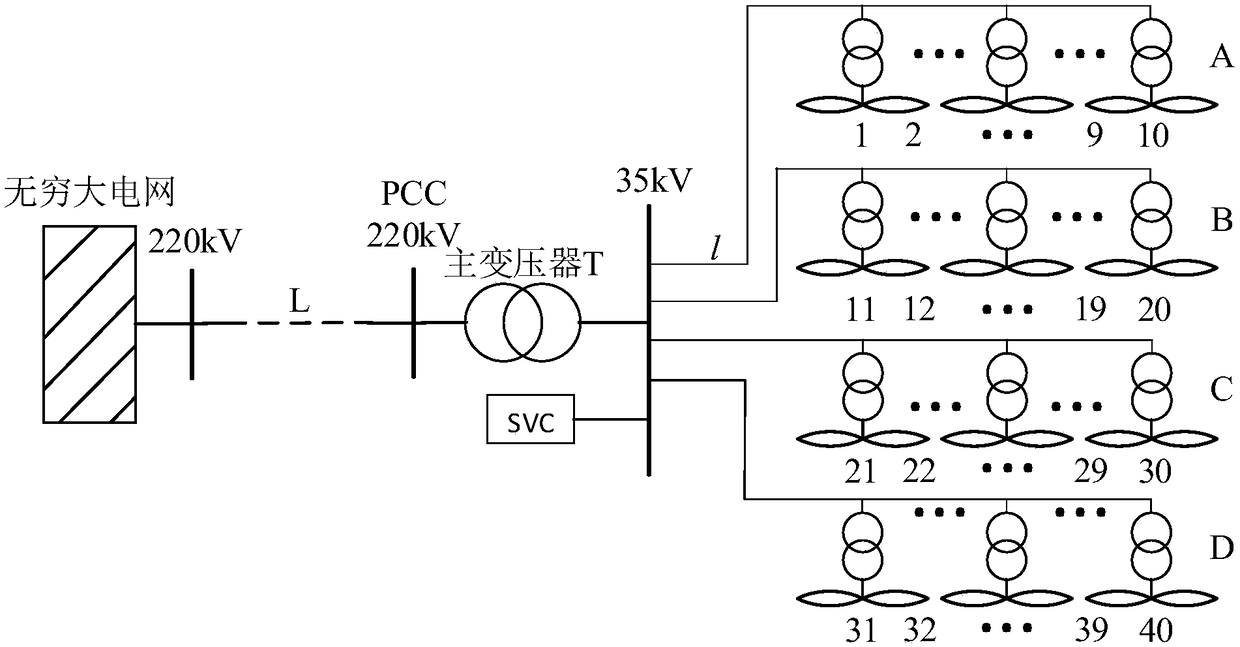

[0029] The verification cases of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the verification cases described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

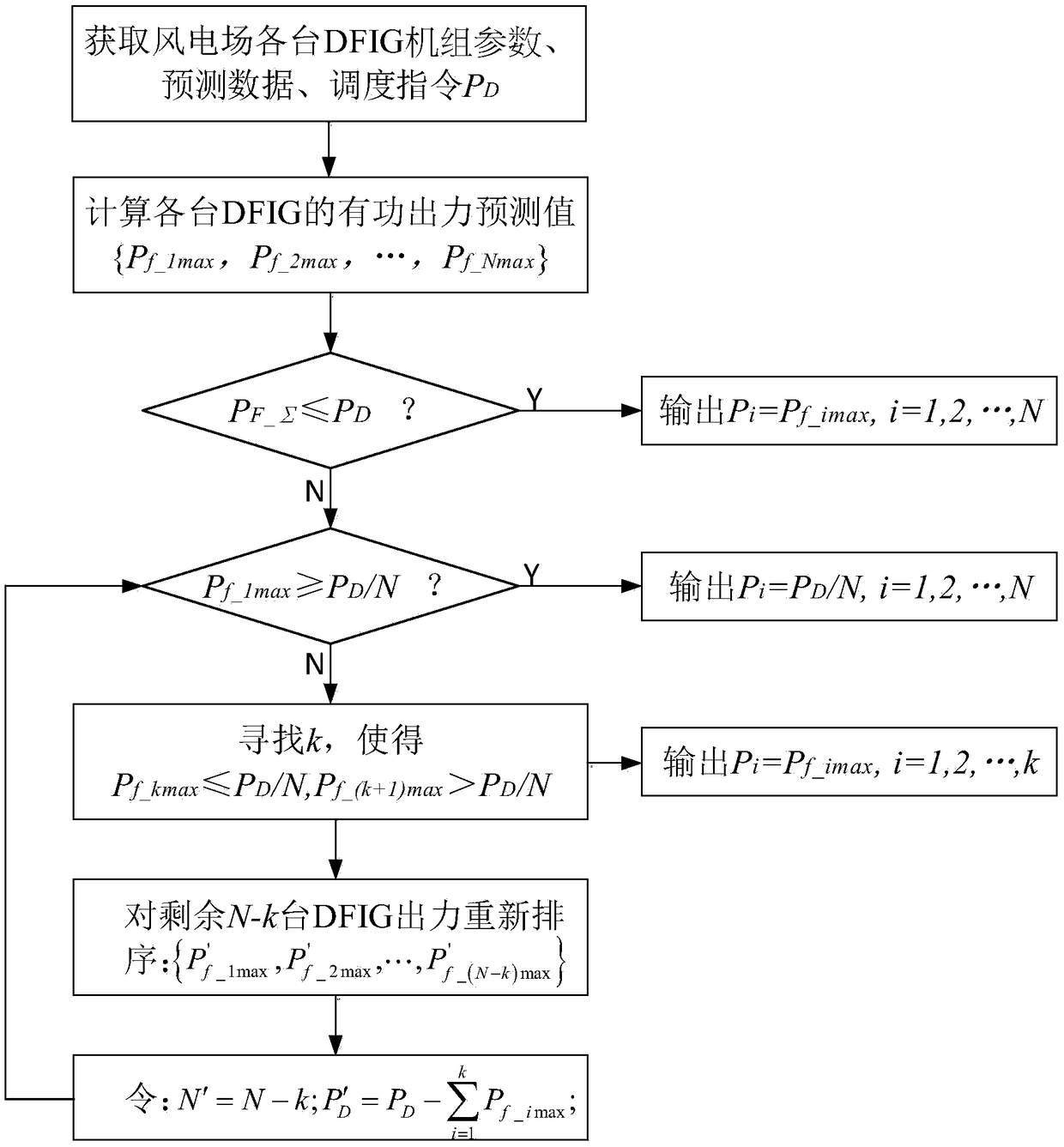

[0030] specifically, figure 1 It is a flow chart of the DFIG active power scheduling method based on the largest wind farm reactive power margin. In Figure 1, the flow chart of the scheduling method includes:

[0031] Step 1: Obtain the parameters of N DFIG units in the wind farm and the predicted value of wind speed v f ={v 1 ,v 2 ,...,v N} and the wind farm active power dispatching command P issued by the superior dispatching center D ;

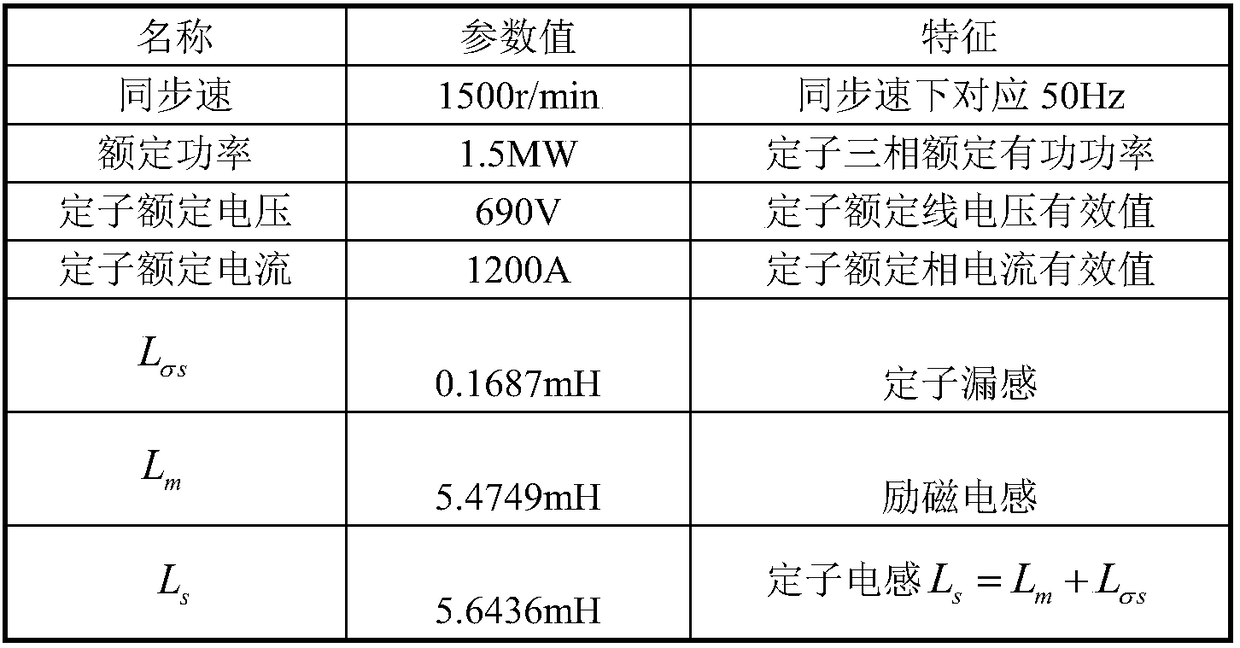

[0032] Step 2: Combined with the dynamic model of the wind turbine, calculate the predicted value of the active output of each DFIG, specifically:

[0033] Step 201: According to the dynamic model of the wind turbine, calculate the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap